值得信赖的数控加工质量控制

了解我们如何通过 ISO 认证流程、严格检查和先进的精密工具确保每个 CNC 加工零件的一致质量。

- 最终产品合格率≥98%

- 准时交货率≥95%

- 顾客满意度≥95%

值得信赖

17年经验

CNC零件加工

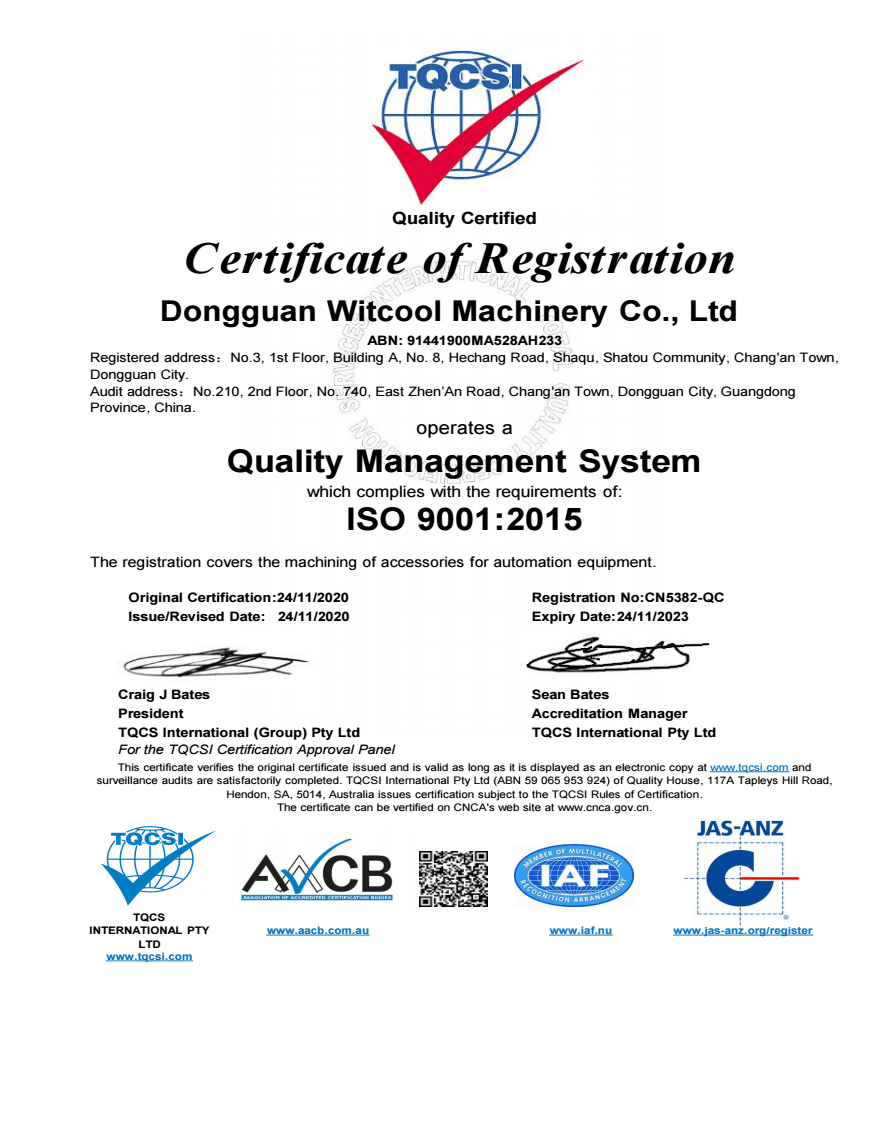

Witcool通过了全球质量标准ISO9001:2015认证,在生产过程中严格遵循质量管理体系。

我们的质量控制团队致力于确保材料质量、加工控制和出厂质量控制,以满足所有客户的要求。我们专注于不断改进我们的质量管理和产品质量。

卓越的定制制造

Witcool 致力于定制制造各个环节的持续改进和优化——从原型设计到大规模生产——包括 CNC 加工、快速原型设计和快速加工。

我们严格遵守ISO 9001:2015质量管理体系,采用标准化生产流程,并配备先进的检测设备。生产过程的每个阶段都经过仔细测量和检验,确保您的项目符合最高的质量标准。

我们的质量方针

先进的制造方法、严格的质量控制和严格标准确保了精度和耐用性。

科学管理: 标准化流程、专业化发展、提高效率、实施最佳实践。

精益制造: 以客户为导向的生产、流程优化、成本控制、供应链改进。

质量和效率: 加强质量控制、改善沟通和员工培训,以提供高质量的产品。

创新与发展: 促进持续学习、知识管理、支持创新、增强公司凝聚力。

CNC 加工中的公差

Witcool 采用先进的 CNC 机器来确保加工部件的高精度。我们提供高达 ±0.005 毫米的公差,使我们能够生产偏差最小且精度极高的部件。

| 图标 | 标准 | 宽容 | 图标 | 标准 | 宽容 | |

|---|---|---|---|---|---|---|

| 常见公差 | 0.0004" (±10μm / ±0.01мм) | 直径公差 | 0.00004" (±1μm / ±0.001мм) | |||

| 平整度 | 0.00004 英寸(2 微米 / 0.002 微米) | 平直度 | 0.00004 英寸(1 微米 / 0.001 мм) | |||

| 垂直度 | 0.0002 英寸(5μм / 0.005мм) | 并行性 | 0.0001" (2.5μм / 0.0025μм) | |||

| 圆度 | 0.0002 英寸(5μм / 0.005мм) | 同心度 | 0.00002" (0.5μм / 0.0005μм) | |||

| 圆柱度 | 0.0002 英寸(5μм / 0.005мм) | 对称 | 0.0003 英寸(8μм / 0.008мм) | |||

|

|

圆跳动 | 0.00004 英寸(1μм / 0.001мм) | 位置公差 | 0.005毫米 |

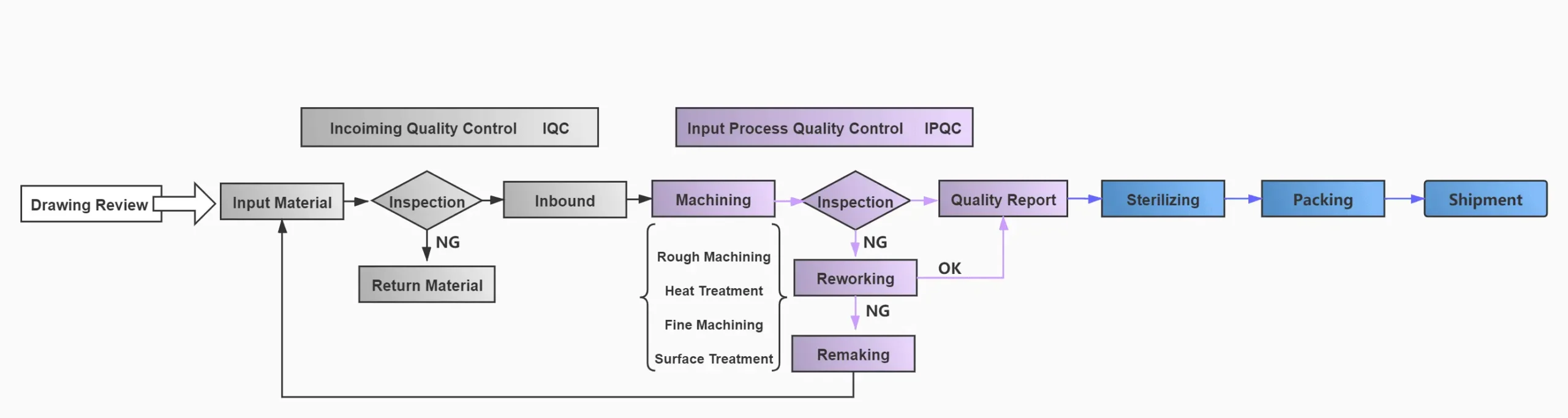

我们的质量控制流程

在 Witcool,我们严格的质量控制流程确保从设计到最终产品的精确度。

检测设备

我们的生产设施配备现代化的检测设备,确保每个生产环节都进行精确的质量检查,确保每个部件都严格符合您的要求和行业标准。

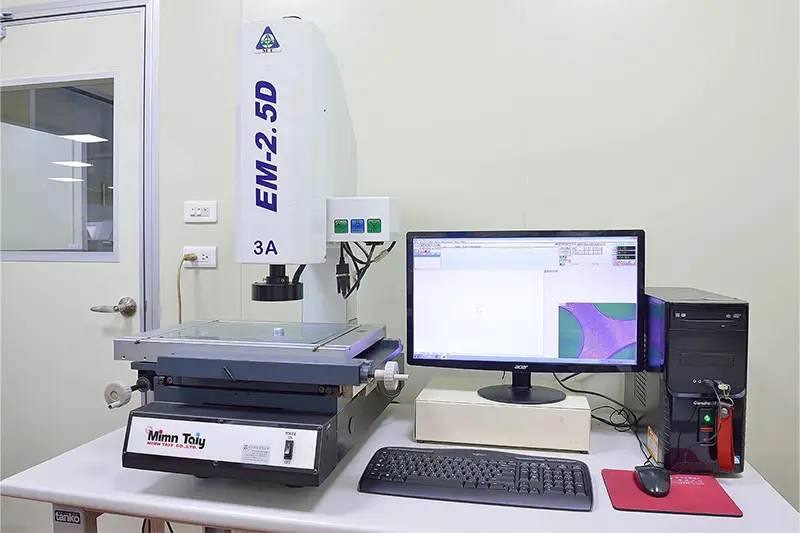

2.5D坐标测量机

用于检查机械加工零件的尺寸和形位公差,确保加工精度满足规定的要求。

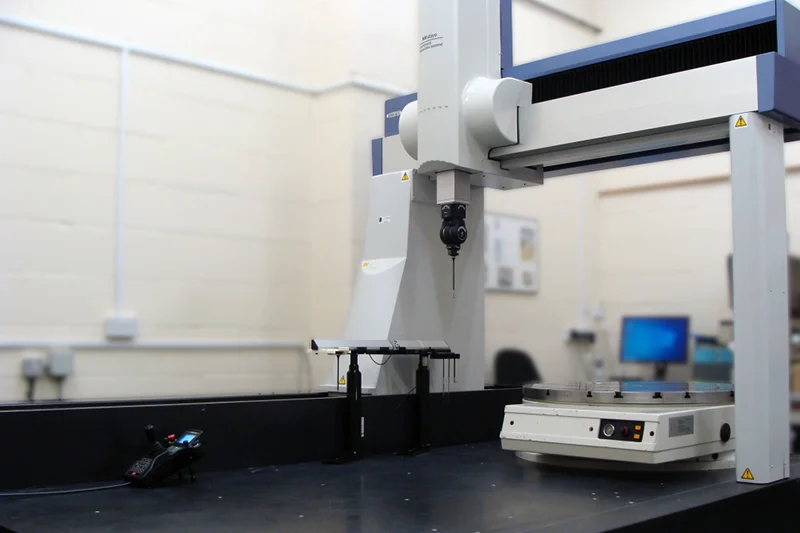

坐标测量机(CMM)

提供尺寸和坐标的精确三维测量,确保零件符合设计图。

光学测量机

用于复杂形状和表面的非接触测量,确保几何精度和控制。

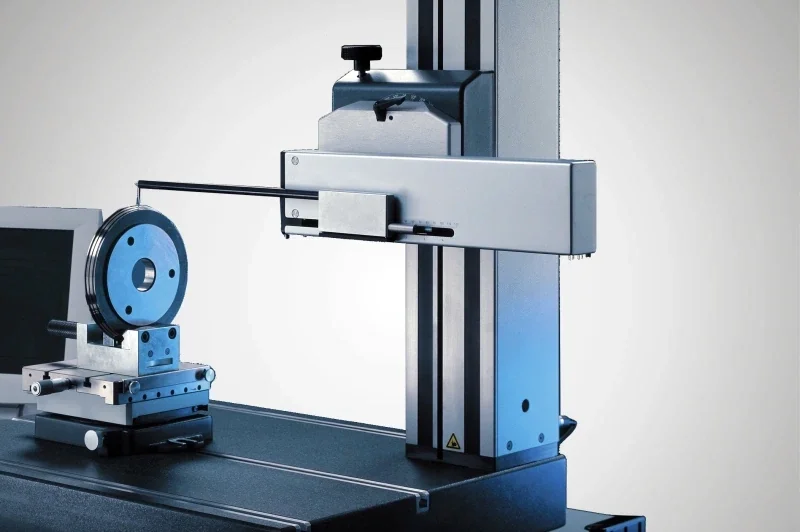

轮廓测量机

检查零件的轮廓和外形,帮助验证是否符合设计要求和标准。

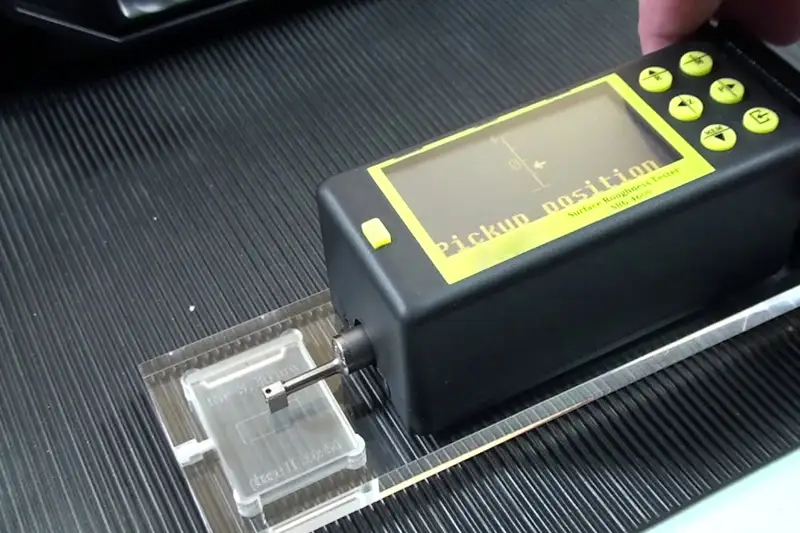

表面粗糙度测试仪

通过测量粗糙度来评估表面质量,这对于零件的功能和耐用性至关重要。

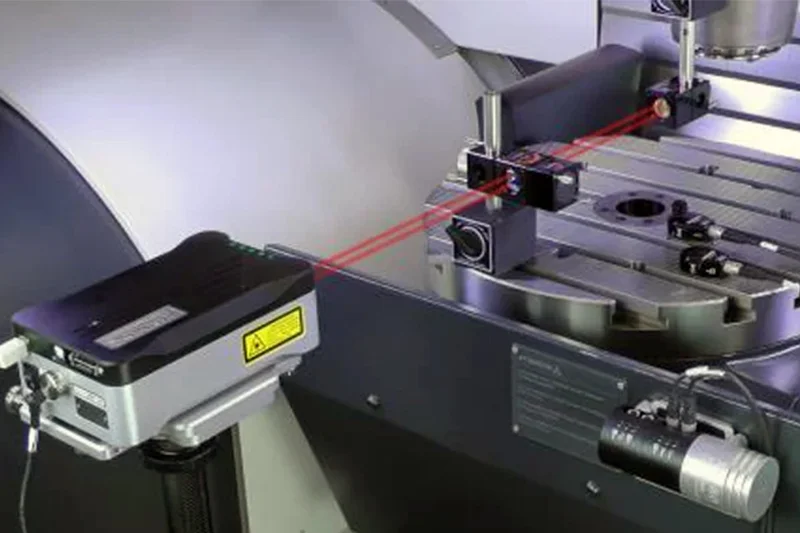

激光干涉仪

使用高精度激光测量监控几何参数和零件对准的准确性。

高度尺

用于测量高度、深度和其他零件尺寸,通常与表面板结合使用。

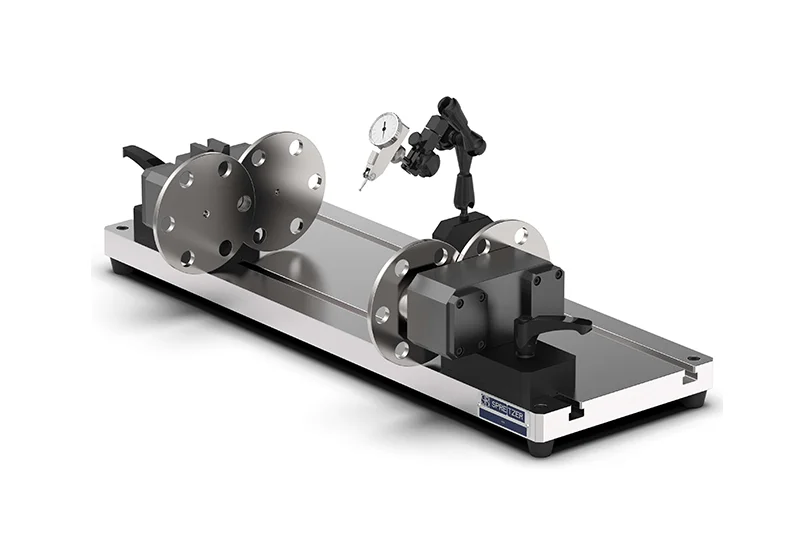

同心度测试仪

测量孔或轴的同心度,以确保机械系统正确对准和运转。

涂层测厚仪

在生产或修复过程中控制涂层的厚度,以确保符合耐用性和保护标准。

硬度计

测量材料的硬度,帮助确定其抵抗机械应力和磨损的能力。

我们的质量文件

Witcool 遵循严格的流程,确保定制部件符合最高的制造标准。我们可根据要求提供证书和报告。以下质量文件适用于我们所有的制造技术,包括 CNC 加工、钣金制造、3D 打印和压铸。

坐标测量机(CMM)检验报告

使用坐标测量机提供精确测量,以验证产品是否符合指定尺寸。

材料证书(仅限金属)

确认金属的成分和质量,确保材料符合标准和可追溯性要求。

标准测量协议

确保使用校准工具进行测量的准确性和一致性,并遵守规定的准确性和公差要求。

首件检验报告 (FAIR)

包括对第一个生产样品的详细检查,以确认符合所有设计和合同要求。

RoHS证书

验证是否符合欧盟 RoHS 指令,确保产品不含有害物质并符合安全法规。

REACH合规证书

确认符合欧盟 REACH 法规,确保化学物质的安全管理并遵守环境标准。

符合性证书

证明产品符合要求和图纸中规定的所有质量和安全标准。

持续改进

在威酷,我们深知持续提升品质和效率是保持竞争力的关键。因此,我们致力于持续改进和优化两个核心领域:

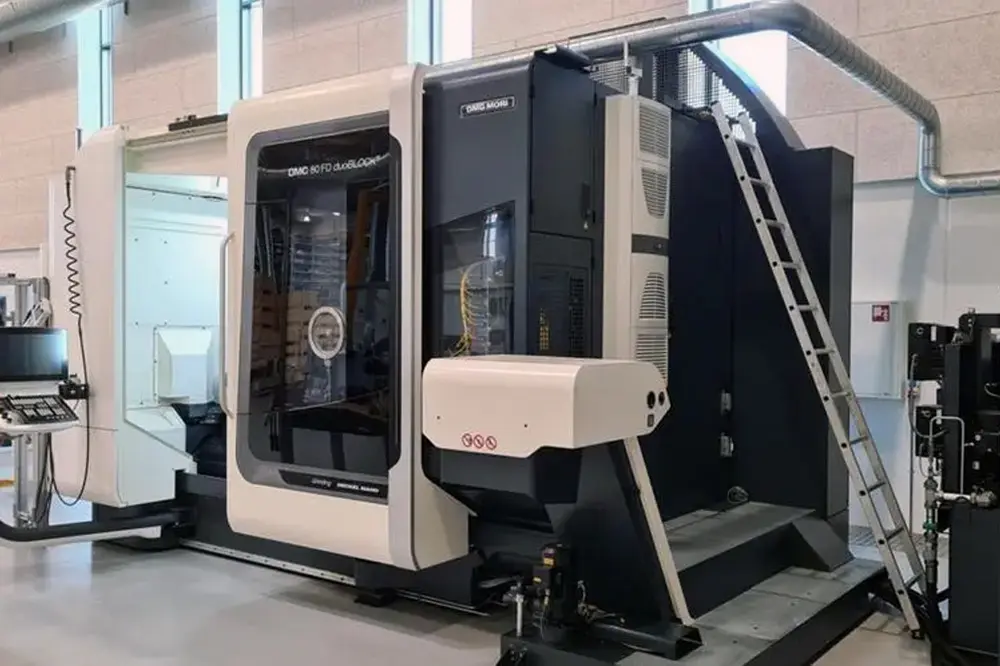

先进设备和技术的实施

我们每两年评估并采用尖端设备和数控加工技术,以确保我们的制造流程与最新的行业进步保持同步。这些升级不仅提高了生产效率,还显著提升了我们产品的精度和质量。例如,我们最近从瑞士引进了一台最先进的五轴加工中心,这极大地提升了我们加工复杂零件的能力。

员工培训与发展

为了确保我们的团队保持与时俱进的知识和技能,我们每三个月进行一次内部培训,并至少每年两次邀请外部专家进行技术交流。此外,我们积极参与中国机械工程学会(CMES)和中国机械工业协会(CMMA)等行业协会组织的培训项目。这些举措帮助我们的员工了解最新的行业趋势,并提高他们解决实际挑战的能力。

问答

在威酷,我们严格控制数控加工过程的每个阶段,确保产品的高质量和高精度。我们遵循标准,并实施创新,提供可靠的解决方案,以提升每个项目的质量。

为什么质量控制在 CNC 加工中很重要?

质量控制确保产品符合既定标准,有助于防止缺陷,保持客户满意度,并支持制造过程的整体可靠性。

CNC加工中的关键质量控制参数有哪些?

主要参数包括尺寸精度、公差、表面光洁度和材料完整性。遵守这些参数对于加工部件的功能至关重要。

CNC加工中如何进行质量检验?

在 Witcool,质量检验包括尺寸测量、材料分析以及使用 CMM 和光学系统等先进的检验设备来验证是否符合规格。

熟练的操作员在确保质量方面发挥什么作用?

我们熟练的操作员可以检测到自动化系统可能错过的细微之处,确保机器具有最佳性能并及早发现潜在问题。

客户如何确保 CNC 加工过程中的保密性?

Witcool 通过应用严格的协议(包括安全文件传输和保密协议 (NDA))优先考虑保密性,以保护您的设计。

如果发现 CNC 加工零件存在质量问题,该怎么办?

一旦发现质量问题,我们将立即停止生产,调查根本原因,并采取纠正措施,防止问题再次发生。如有任何延误或问题,我们将及时通知客户。