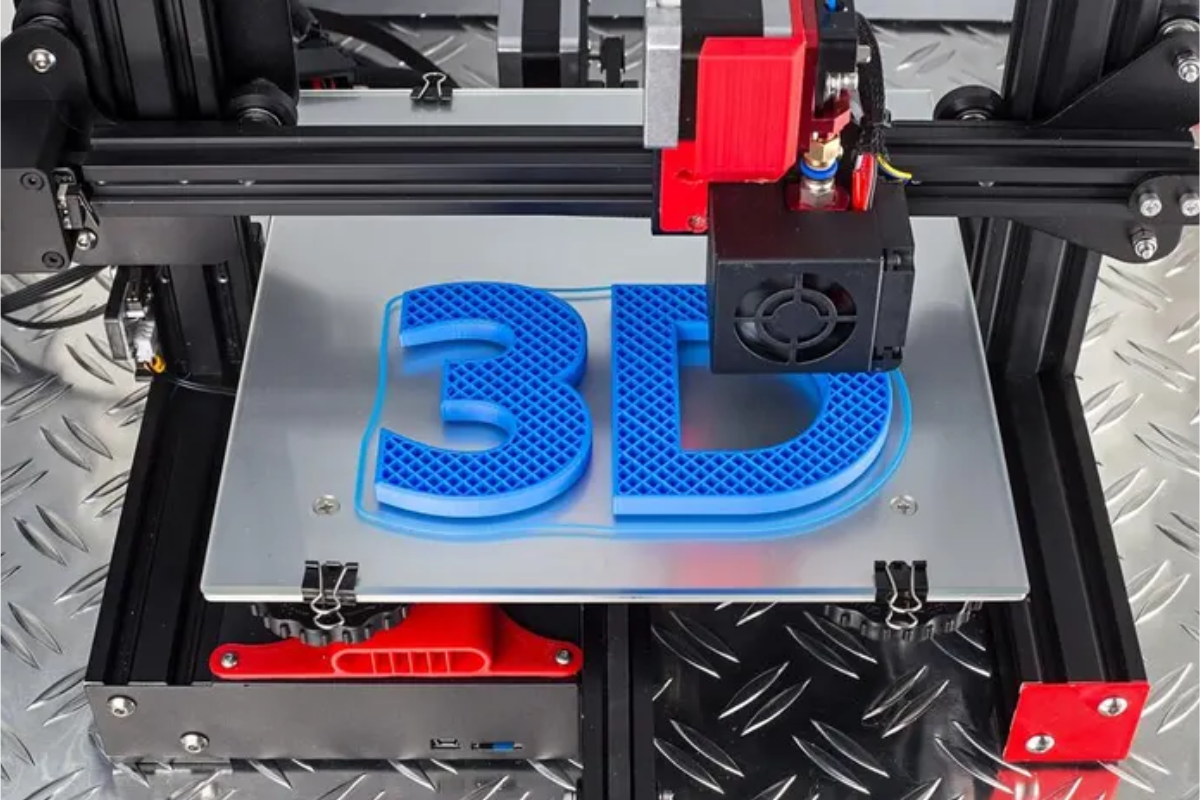

3D打印彻底改变了制造业,为原型设计和小批量生产提供了灵活的解决方案。但任何3D打印部件的成功都始于选择合适的材料。在Witcool,我们深知材料选择并非易事——因此,我们在此提供一份概述,以帮助您做出明智的决定。

常见的3D打印材料类型

1.塑料(聚合物)

- PLA(聚乳酸):

一种可生物降解、易于打印的塑料。成本低廉、色彩丰富,是制作原型和视觉模型的理想选择。 - ABS(丙烯腈丁二烯苯乙烯):

耐用且抗冲击,适用于功能部件、外壳和汽车应用。 - PETG(聚对苯二甲酸乙二醇酯):

兼具强度和柔韧性;用于需要耐化学性的机械零件、容器和组件。 - 尼龙(聚酰胺):

坚固、灵活、耐磨——常用于齿轮、铰链和工业部件。

2.树脂

- 标准树脂:

提供高细节和光滑的表面,非常适合原型、牙科模型和珠宝。 - 工程树脂:

专用树脂可增加强度、柔韧性或耐热性;适用于功能原型和最终用途部件。

3.金属

- 不锈钢、铝、钛:

用于航空航天、汽车和医疗植入物的工业3D打印。这些金属具有优异的强度、耐热性和耐用性。 - 应用:

高性能、承重组件、定制工具和功能性最终用途零件。

4.复合材料

- 碳纤维或玻璃纤维增强:

填充纤维的塑料或尼龙,用于增强强度和刚度。用于汽车、机器人和无人机部件。

如何选择合适的材料

- 目的: 您的零件是原型、功能工具还是最终用途产品?

- 机械性能: 考虑强度、柔韧性、耐用性和耐温性。

- 表面处理: 您需要的是流畅的外观,还是功能特性更重要?

- 行业要求: 某些应用,例如医疗或航空航天,需要经过认证的材料。

Witcool的3D打印能力

在Witcool,我们提供各种3D打印材料,以满足您项目的需求——从快速原型到可直接生产的部件。我们的专家可以根据您的规格推荐最佳材料,帮助您快速高效地获得最佳效果。

结论

选择合适的 3D 打印材料是项目成功的关键。随着塑料、树脂、金属和复合材料等材料的不断涌现,制造商如今拥有比以往更大的灵活性。请联系 Witcool 探讨您的项目,并找到适合您业务的理想 3D 打印解决方案。