机器人和自动化部件的 CNC 加工

CNC加工保证了精确的尺寸和公差,提高了机器人的性能和可靠性。机器人和CNC加工的结合使生产更加灵活和智能。

- 确保最小公差和高精度。

- 减少浪费并加速生产。

- 适用于加工铝和钢等金属。

- 保证批量生产的可重复性。

值得信赖

为什么 CNC 加工对机器人如此重要

CNC 加工为机器人提供精密的零件,增强其稳定性和可靠性。CNC 机床可制造复杂的组件,加工各种材料,确保耐用性和一致性。

- 高精度:

关节、齿轮等关键部件需要微米级的精度,而这可以通过CNC加工来实现。 - 复杂设计:

CNC 机器可以加工复杂的形状,确保机器人的功能。 - 材料选择:

CNC 可以加工从铝到钛的各种材料,确保在高负载条件下的耐用性。 - 可靠性:

CNC加工的零件精度高,确保系统性能稳定。

服务和解决方案

Witcool CNC Machining 提供高精度 CNC 加工服务,提供推动创新并在零件制造中提供卓越性能的定制解决方案。

数控加工

通过铣削、车削和后处理创建精确而复杂的结构,非常适合复杂的原型和功能性金属零件。

压铸

快速生产铸件和中间工具,并针对一致的质量进行优化以进行大规模生产。

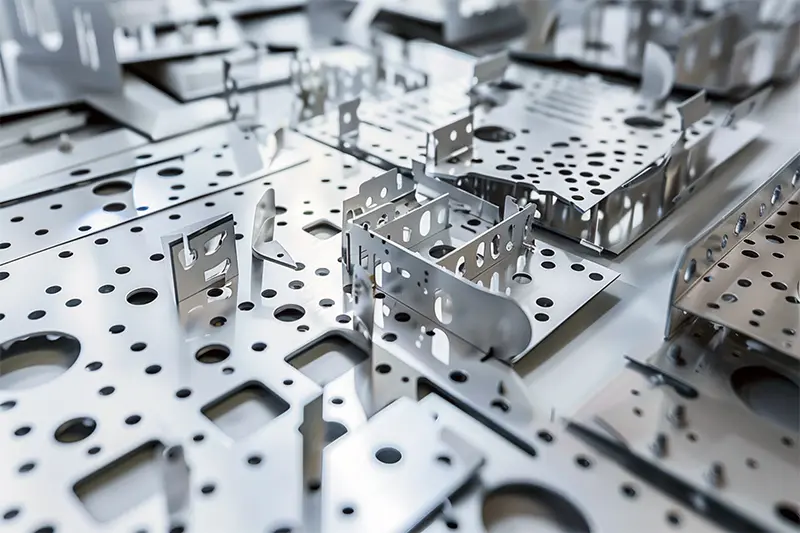

钣金加工

为各种应用提供形成精密金属部件的灵活性,确保适应性和准确性。

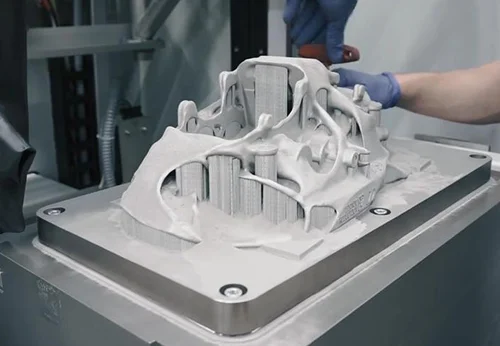

3D 打印

一种快速而多功能的工艺,可使用多种材料快速创建复杂的形状,非常适合创新设计。

材料和表面处理

材料

我们提供各种材料,包括金属、塑料和复合材料。

表面处理

我们的高品质表面处理增强了零件的耐用性和外观,满足了光滑表面和纹理表面的要求。

机器人制造能力

凭借在机器人行业的丰富专业知识,Witcool 与 ABB 和 Universal Robots 合作,提供顶级 CNC 加工解决方案。我们致力于精准和创新,这使我们能够制造符合严格质量标准的复杂机器人组件。通过采用尖端技术,我们始终与合作伙伴不断变化的需求保持一致。

“我们对 CNC 加工团队提供的精度和质量印象深刻。他们为我们的工业机器人提供的结构部件在精度、耐用性和轻量化设计方面超出了我们的预期。他们能够满足严格的公差并在我们加快的时间表内交付原型,这对我们的产品开发过程至关重要。我们期待在未来的项目上继续合作!” ---- ABB 机器人

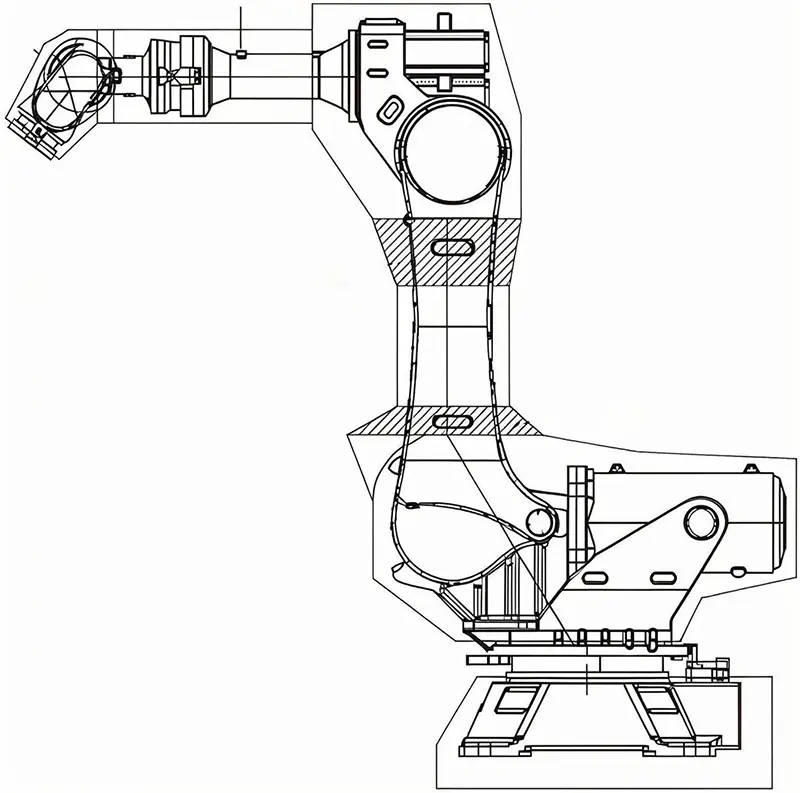

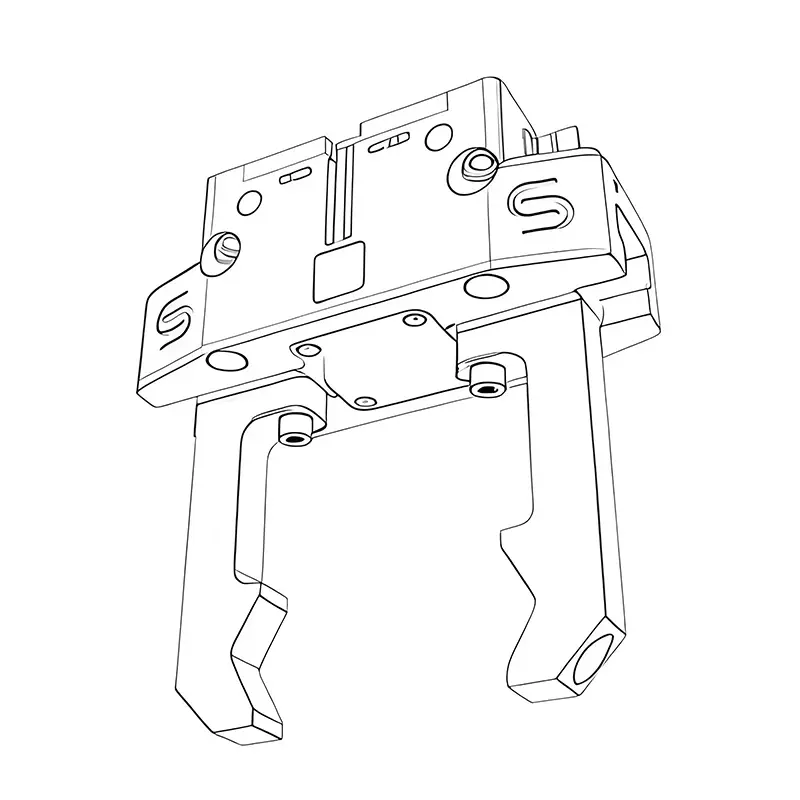

工业机器人框架的精密数控加工

ABB Robotics 需要为其工业机器人配备高精度结构部件,包括底座和关节外壳。这些部件需要严格的公差以确保平稳运行和结构稳定性。这些部件专为汽车制造和物流自动化等行业的重型应用而设计。

● 5 轴 CNC 加工: 实现复杂的几何形状和高精度。

● 铝合金加工: 轻质耐用的材料可提高机器人的效率。

● 表面处理: 阳极氧化可提高耐腐蚀性并延长使用寿命。

1.尺寸精度达到±0.005mm以内,满足ABB的严格要求。

2、部件重量减少15%,提升机器人的能源效率。

3.两周内交付原型,加快了ABB的开发时间表。

“CNC 加工团队提供的定制装配夹具和固定装置大大提高了我们的生产效率。他们对细节的关注和实现严格公差的能力确保了我们协作机器人装配过程中始终如一的质量。我们也感谢他们致力于在不影响质量的情况下满足我们严格的时间表。他们是值得信赖的合作伙伴,我们强烈推荐他们的服务。” ---- Universal Robots

协作机器人装配夹具的精密数控

Universal Robots 需要定制的装配夹具和固定装置来简化其协作机器人 (Cobot) 的生产。这些工具需要确保在装配和测试过程中精确对准,最大限度地减少人为错误并提高生产效率。

● 3 轴 CNC 加工: 非常适合生产高精度平面和角表面。

● 高强度钢加工: 能够承受制造环境中的反复使用。

● 定制设计: 针对 Universal Robots 独特的装配工作流程进行定制。

1.通过20%增强了装配精度,大大降低了返工率。

2.制造的夹具公差为±0.01毫米,确保质量始终如一。

3. 在四周内交付工具,满足了 Universal Robots 紧张的生产计划。

将机器人技术与 CNC 加工相结合的好处

Witcool CNC Machining 提供高精度 CNC 加工服务,提供定制解决方案,促进创新并在零件制造中提供出色的性能。

提高生产力

机器人可以连续运行,无需休息或疲劳,从而提高生产量并缩短交货时间。这使得制造更加高效和及时。

提高精度

机器人可以实现高精度,这在生产医疗设备和其他应用的复杂组件时尤为重要。高精度可确保产品质量稳定,并减少差异。

降低成本

从长远来看,使用机器人可以减少劳动力成本并最大限度地减少错误,通过降低劳动力费用和缺陷纠正带来显著的经济效益。

灵活性和可扩展性

机器人系统可以轻松重新配置以执行各种任务,使制造商能够适应不断变化的生产需求。这确保了生产管理的灵活性,并能够扩大生产以满足不断增长的需求。

质量保证

Witcool 提供≤5μm 的 CNC 精度(通过 ISO 9001:2015 认证),QA 通过率为 99.8%。5 阶段检查流程确保机器人组件符合 MIL-STD-1916 标准。自 2012 年以来,已为 200 多家工业机器人制造商提供服务,缺陷率为 0.002%。医疗级钛加工能力(符合 ISO 13485 标准)。

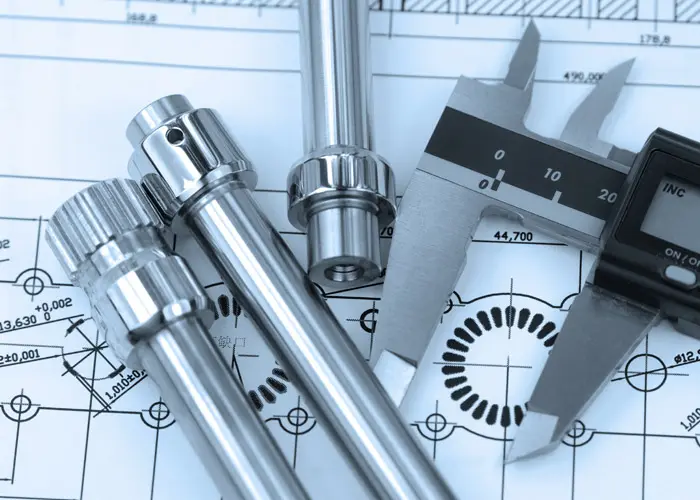

精密加工与质量控制

在机器人行业,CNC 加工对于生产执行器、齿轮和机械臂等关键部件至关重要。Witcool 在生产的每个阶段都实施严格的质量控制措施,确保每个零件都符合最严格的公差规范。我们实施了全面质量管理 (TQM) 系统,实时监控每个生产步骤,以最大限度地减少缺陷和错误。为了保证整个过程的精确度,我们使用先进的坐标测量机 (CMM) 和光学测量系统。

质量控制流程:

原材料检验:

生产开始前,所有材料都经过严格检查,以确保符合设计标准和行业规范。

过程检验:

在生产的每个关键阶段,都会实施控制检查点,以防止错误的积累并确保符合规范。

最终检查和验证:

生产完成后,会对尺寸、表面质量和公差进行彻底检查,以确保完全符合技术要求。

- 这些流程确保每个阶段的最高质量,保证最终产品的可靠性。

认证和行业标准

我们的制造业务已通过 ISO 9001 认证,确保所有机器人组件均符合国际质量标准。此外,我们的材料和工艺符合 RoHS 和 REACH 等行业法规,确保符合环境和安全标准。

材料和加工标准

机器人部件需要具有高强度、高精度和耐用性的材料。Witcool 选择符合行业规范的材料,包括铝合金、不锈钢和钛合金,并采用优化的加工参数,以保证完全符合严格的要求。

产品测试和验证

Witcool 在每个生产阶段都进行全面的测试和验证,包括疲劳、耐腐蚀和冲击强度测试,这些测试对于机器人部件至关重要。这些测试验证了我们的零件在极端条件下的卓越性能和可靠性。

具体测试和验证流程:

疲劳测试:

模拟长期使用过程中组件的负载应力,以防止在张力下发生故障。

耐腐蚀测试:

评估暴露在高湿度或腐蚀性环境中的部件的材料耐腐蚀性能。

冲击测试:

评估部件在突然冲击或高压下的强度和耐久性。

尺寸验证:

使用高精度测量系统测量零件精度,以确保符合微米级公差。

综合追踪系统

威酷采用数字化追溯系统,记录从原材料到成品的每个阶段,确保生产过程随时可追溯。此方法可提高管理透明度,并有助于快速解决潜在的质量问题。

客户反馈和持续改进

我们积极听取机器人行业客户的反馈意见,不断提高我们的 CNC 加工能力。通过改进我们的工艺和采用尖端的加工技术,Witcool 确保交付的机器人部件超出了行业的最高标准。

常见问题

CNC 加工在机器人技术中至关重要,它可以精密制造框架、接头和工具等零件,同时通过高质量的解决方案支持创新和自动化。

CNC加工在机器人技术中扮演什么角色?

CNC 加工对于制造机器人系统中使用的精密部件(包括框架、接头和定制工具)至关重要。

哪些类型的机器人部件是使用 CNC 加工制造的?

CNC加工可生产高精度、高质量的机器人框架、齿轮系统、外壳、末端执行器和装配夹具。

CNC加工的机器人零件通常使用哪些材料?

铝、钛、不锈钢和工程塑料等材料由于强度高、重量轻而被经常使用。

CNC加工如何确保机器人部件的准确性?

CNC 加工使用先进的软件和多轴机器来实现严格的公差和一致的精度。

为什么 CNC 加工是机器人零件原型制作的首选?

CNC 加工具有生产速度快、精度高、处理复杂设计的灵活性等特点,非常适合制作原型。

CNC加工可以处理机器人的定制设计吗?

是的,CNC加工高度适应独特和复杂的设计,满足机器人应用的特定要求。