Sheet metal fabrication is a vital process in today’s manufacturing industry, enabling the production of everything from intricate electronic enclosures to robust automotive components. At Witcool, we specialize in delivering high-quality sheet metal solutions that meet the exacting needs of diverse industries worldwide.

What Is Sheet Metal Fabrication?

Sheet metal fabrication is the process of turning flat sheets of metal—such as aluminum, stainless steel, or carbon steel—into finished parts and assemblies. It combines a series of manufacturing techniques to achieve precise shapes, dimensions, and features tailored to specific applications.

Key Processes in Sheet Metal Fabrication

- Cutting:

Methods include laser cutting, waterjet cutting, and shearing, allowing for highly accurate and complex shapes. - Bending:

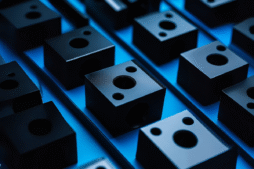

Performed with press brakes or folding machines to create angles, curves, and structural features. - Punching:

Used to create holes, slots, or custom cutouts for fasteners, wiring, or ventilation. - Welding:

Joins multiple metal parts together for strength and durability—commonly used in chassis, frames, and enclosures. - Surface Treatment:

Finishing processes like powder coating, anodizing, or plating enhance appearance and protect against corrosion.

Common Materials Used

- Stainless Steel: Corrosion-resistant and durable, ideal for medical devices, food equipment, and architectural features.

- Aluminum: Lightweight with good conductivity, often used in automotive, aerospace, and electronics.

- Carbon Steel: Strong and cost-effective, suitable for industrial machinery and structural parts.

- Copper & Brass: Used where electrical or thermal conductivity is important.

Applications Across Industries

Sheet metal fabrication serves a wide range of industries, including:

- Automotive: Body panels, brackets, and structural parts.

- Electronics: Housings, enclosures, and heat sinks.

- Aerospace: Lightweight structural components.

- Medical: Equipment frames and enclosures.

- Industrial Machinery: Panels, guards, and custom assemblies.

Why Choose Witcool for Sheet Metal Fabrication?

- Precision Engineering: Tight tolerances and consistent quality.

- Flexible Production: From rapid prototypes to mass production.

- Comprehensive Service: One-stop solutions including design support, material sourcing, fabrication, finishing, and assembly.

- Strict Quality Control: Every part is inspected to meet customer specifications and international standards.

Conclusion

Sheet metal fabrication is essential for creating durable, functional, and customized metal parts across countless industries. With advanced equipment, skilled engineers, and a commitment to quality, Witcool delivers reliable sheet metal solutions tailored to your business needs.

Ready to start your next project? Contact Witcool today to learn more about our sheet metal fabrication capabilities.