Apakah Kemasan Oksida Hitam?

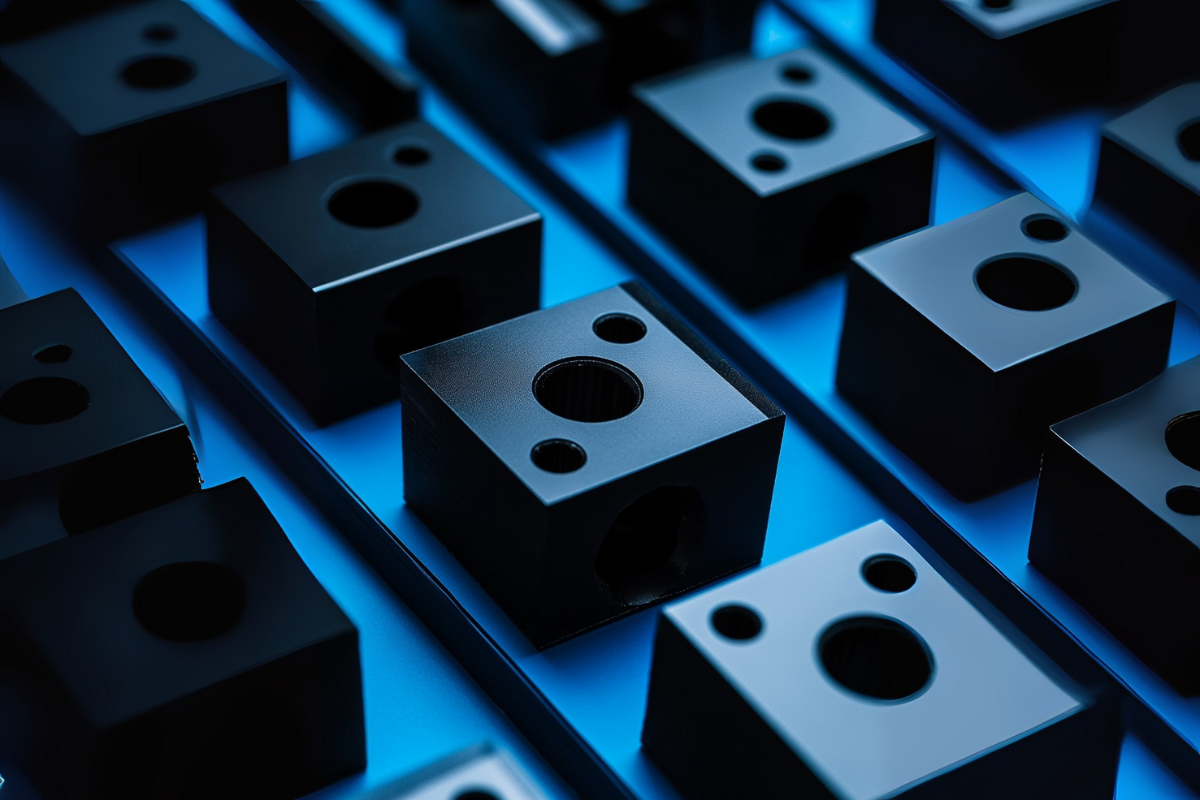

Oksida hitam penamat ialah rawatan permukaan kimia yang popular untuk keluli dan logam ferus lain. Ia menghasilkan lapisan licin, hitam, tahan kakisan tanpa mengubah dimensi bahagian dengan ketara. Digunakan secara meluas dalam pembuatan, oksida hitam dinilai untuk kedua-dua ciri fungsi dan estetiknya.

Jenis & Langkah Proses

Jenis:

- Oksida hitam panas: Mandi pada ~141 °C menggunakan NaOH dan nitrat; membentuk lapisan magnetit dan memerlukan pengedap minyak.

- Suhu pertengahan: Suhu rendah, kurang asap; kimia dan keputusan yang serupa.

- Oksida hitam sejuk: Proses suhu bilik mendepositkan kuprum‑selenide daripada oksida sebenar; lebih mudah untuk penggemar tetapi kurang tahan lama

Langkah Proses:

The proses oksida hitam melibatkan merendam bahagian keluli dalam satu siri mandian kimia. Berikut ialah aliran kerja biasa:

- Pembersihan: Bahagian dibersihkan dengan teliti untuk menghilangkan minyak, karat dan kerak.

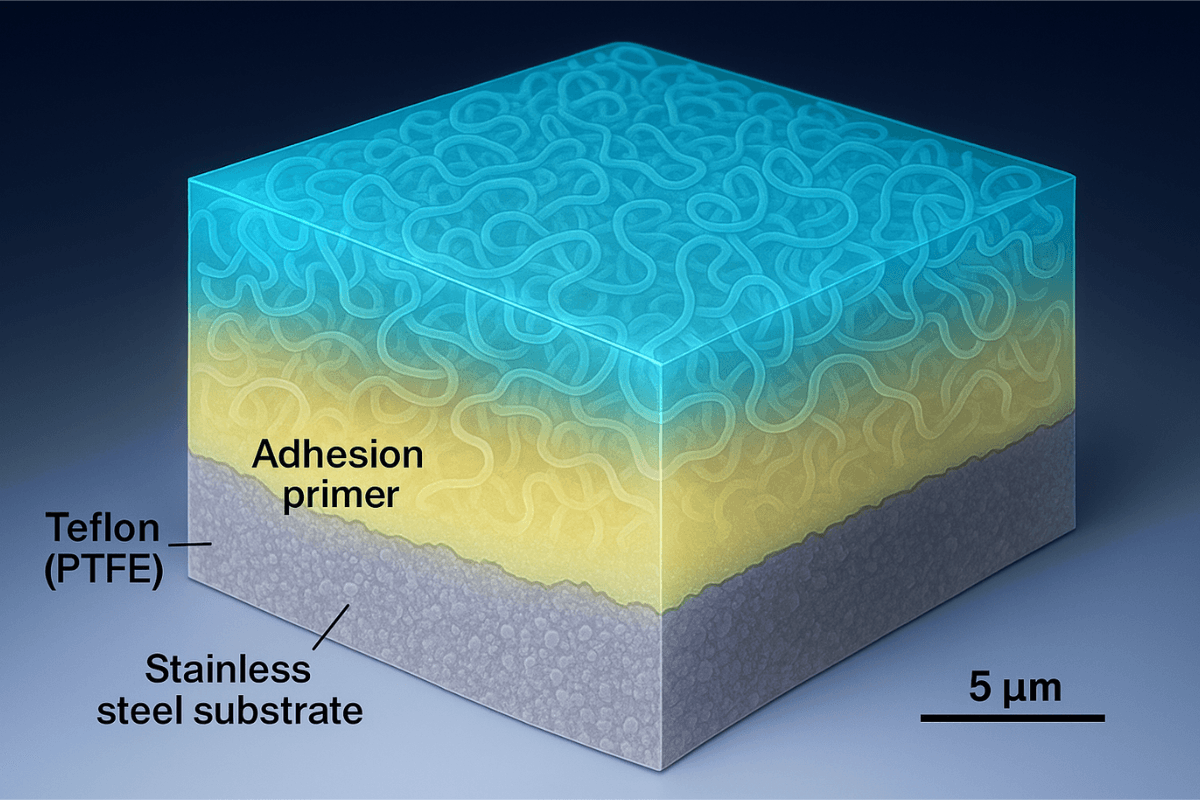

- menghitam: Bahagian yang dibersihkan diletakkan dalam larutan alkali panas yang mengandungi garam pengoksida. Tindak balas membentuk lapisan magnetit (Fe₃O₄) pada permukaan keluli.

- Membilas: Bahagian dibilas untuk menghilangkan bahan kimia.

- pengedap: Sealant (selalunya minyak atau lilin) digunakan untuk meningkatkan ketahanan kakisan.

Faedah Utama Oksida Hitam untuk Keluli

Rintangan kakisan: Lapisan oksida hitam memberikan perlindungan sederhana terhadap karat, terutamanya apabila ditutup dengan minyak.

Penampilan yang Diperbaiki: Memberi bahagian kemasan seragam, hitam matte, mengurangkan silau dan meningkatkan estetika.

Kestabilan Dimensi: Salutan sangat nipis (0.5–2.5 mikron), mengekalkan toleransi yang ketat.

Kos-Efektif: Kos yang lebih rendah daripada penyaduran atau pengecatan, terutamanya untuk pengeluaran volum tinggi.

Pelinciran: Mengurangkan geseran pada bahagian yang bergerak.

Aplikasi Perindustrian

Kemasan oksida hitam untuk keluli digunakan dalam:

- Automotif: Pengikat, bahagian enjin, kurungan

- Kejuruteraan Aeroangkasa & Ketepatan: Gear, galas, komponen toleransi tinggi

- Senjata api & Alatan: Bahagian pistol, sepana, perkakasan, alatan pembedahan

- Komponen Mesin & Elektronik: Lekapan, suis, alatan elektrik

Perbandingan dengan Kaedah Kemasan Logam Lain

| Kaedah | Ketebalan | Rintangan Kakisan | Penampilan | kos |

|---|---|---|---|---|

| Oksida Hitam | ≤ 2 µm | Sederhana (apabila dimeterai) | Hitam Matte | rendah |

| Penyaduran Zink | Lebih tebal | lebih baik | Logam terang | Sederhana |

| Salutan Serbuk | tebal | Cemerlang | Pelbagai warna yang luas | Lebih tinggi |

| Anodizing (Aluminium) | Nipis ke sederhana | Tinggi (penebat) | Pelbagai warna | Sederhana hingga tinggi |

Soalan Lazim

S: Adakah kemasan oksida hitam berfungsi untuk semua logam?

A: Oksida hitam terutamanya untuk logam ferus (keluli, besi). Proses khas diperlukan untuk keluli tahan karat, tembaga, atau zink.

S: Sejauh manakah tahan lama salutan oksida hitam?

J: Ia menawarkan rintangan haus dan kakisan sederhana, terutamanya apabila disapu minyak, tetapi tidak sekukuh salutan yang lebih tebal.

S: Bagaimanakah bahagian bersalut oksida hitam harus dikekalkan?

J: Bahagian oksida hitam hendaklah sentiasa disapu minyak atau wax untuk mengekalkan ketahanan kakisannya. Elakkan pembersih atau bahan pelelas yang keras yang boleh menanggalkan lapisan pelindung dan mengurangkan keberkesanan.

S: Bolehkah oksida hitam digunakan pada logam bukan keluli?

ya. Keluli tahan karat, tembaga, zink, dan juga logam serbuk boleh dihitamkan menggunakan proses yang disesuaikan; kaedah sejuk selalunya menggunakan kuprum-selenide dan bukannya magnetit.

S: Adakah kemasan oksida hitam menjejaskan sifat mekanikal bahagian keluli?

J: Tidak, kemasan oksida hitam tidak menjejaskan sifat mekanikal keluli, seperti kekuatan atau kekerasan. Ia adalah rawatan permukaan yang sangat nipis yang terutamanya meningkatkan penampilan dan rintangan kakisan tanpa mengubah bahan asas.

S: Adakah kemasan oksida hitam mesra alam?

J: Kemasan oksida hitam menggunakan bahan kimia yang memerlukan pengendalian dan pelupusan yang teliti, tetapi banyak kemudahan moden mengikut peraturan alam sekitar dan keselamatan yang ketat. Sesetengah proses telah dibangunkan untuk mengurangkan kesan alam sekitar, jadi sentiasa pilih pembekal yang bereputasi baik yang mengikut amalan mesra alam.

Kesimpulan & Sumber Lanjutan

Kemasan oksida hitam untuk keluli ialah cara yang cekap untuk meningkatkan penampilan, mengurangkan silau dan menawarkan perlindungan kakisan. Salutan nipis, kos efektif adalah sesuai untuk banyak bahagian industri. Untuk penyelesaian kemasan oksida hitam tersuai atau untuk mengetahui lebih lanjut tentang perkhidmatan kami, hubungi kami atau kunjungi kami kategori rawatan permukaan keluli.