판금 제작은 오늘날 제조 산업에서 필수적인 공정으로, 정교한 전자 케이스부터 견고한 자동차 부품까지 모든 것을 생산할 수 있습니다. Witcool은 전 세계 다양한 산업의 엄격한 요구를 충족하는 고품질 판금 솔루션을 제공하는 데 특화되어 있습니다.

판금 제작이란?

판금 가공은 알루미늄, 스테인리스강, 탄소강 등의 평평한 금속판을 완제품 및 조립품으로 만드는 공정입니다. 다양한 제조 기술을 결합하여 특정 용도에 맞는 정밀한 모양, 치수 및 기능을 구현합니다.

판금 제작의 핵심 공정

- 절단:

레이저 절단, 워터젯 절단, 전단 등의 방법을 사용하여 매우 정확하고 복잡한 모양을 만들 수 있습니다. - 굽힘:

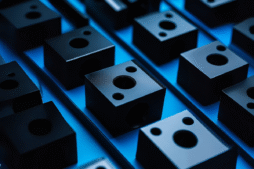

각도, 곡선 및 구조적 특징을 만들기 위해 프레스 브레이크나 폴딩 머신을 사용하여 수행됩니다. - 펀칭:

패스너, 배선 또는 환기를 위한 구멍, 슬롯 또는 맞춤형 컷아웃을 만드는 데 사용됩니다. - 용접:

여러 개의 금속 부품을 연결하여 강도와 내구성을 높입니다. 일반적으로 섀시, 프레임, 인클로저에 사용됩니다. - 표면 처리:

분말 코팅, 양극 산화 처리, 도금과 같은 마감 공정을 통해 외관이 좋아지고 부식을 방지할 수 있습니다.

일반적으로 사용되는 재료

- 스테인리스 스틸: 부식 방지 및 내구성이 뛰어나 의료 기기, 식품 장비, 건축적 특징에 이상적입니다.

- 알류미늄: 가볍고 전도성이 좋으며, 자동차, 항공우주, 전자제품에 자주 사용됩니다.

- 탄소강: 견고하고 비용 효율적이며 산업용 기계 및 구조 부품에 적합합니다.

- 구리 및 황동: 전기나 열의 전도도가 중요한 곳에 사용됩니다.

산업 전반에 걸친 응용 프로그램

판금 제작은 다음을 포함한 광범위한 산업에 적용됩니다.

- 자동차: 차체 패널, 브라켓 및 구조 부품.

- 전자제품: 하우징, 인클로저 및 방열판.

- 항공우주: 가벼운 구조적 구성 요소.

- 의료: 장비 프레임 및 인클로저.

- 산업용 기계: 패널, 가드 및 맞춤형 조립품.

판금 제작을 위해 Witcool을 선택해야 하는 이유는 무엇입니까?

- 정밀공학: 엄격한 허용 오차와 일관된 품질.

- 유연한 생산: 신속한 프로토타입부터 대량 생산까지.

- 종합 서비스: 설계 지원, 자재 조달, 제작, 마무리, 조립을 포함한 원스톱 솔루션을 제공합니다.

- 엄격한 품질 관리: 모든 부품은 고객 사양과 국제 표준을 충족하는지 검사됩니다.

결론

판금 제작은 수많은 산업 분야에서 내구성과 기능성을 갖춘 맞춤형 금속 부품을 제작하는 데 필수적입니다. Witcool은 첨단 장비, 숙련된 엔지니어, 그리고 품질에 대한 헌신을 바탕으로 고객의 비즈니스 요구에 맞춘 신뢰할 수 있는 판금 솔루션을 제공합니다.

다음 프로젝트를 시작할 준비가 되셨나요? 지금 바로 Witcool에 문의하여 판금 제작 역량에 대해 자세히 알아보세요.