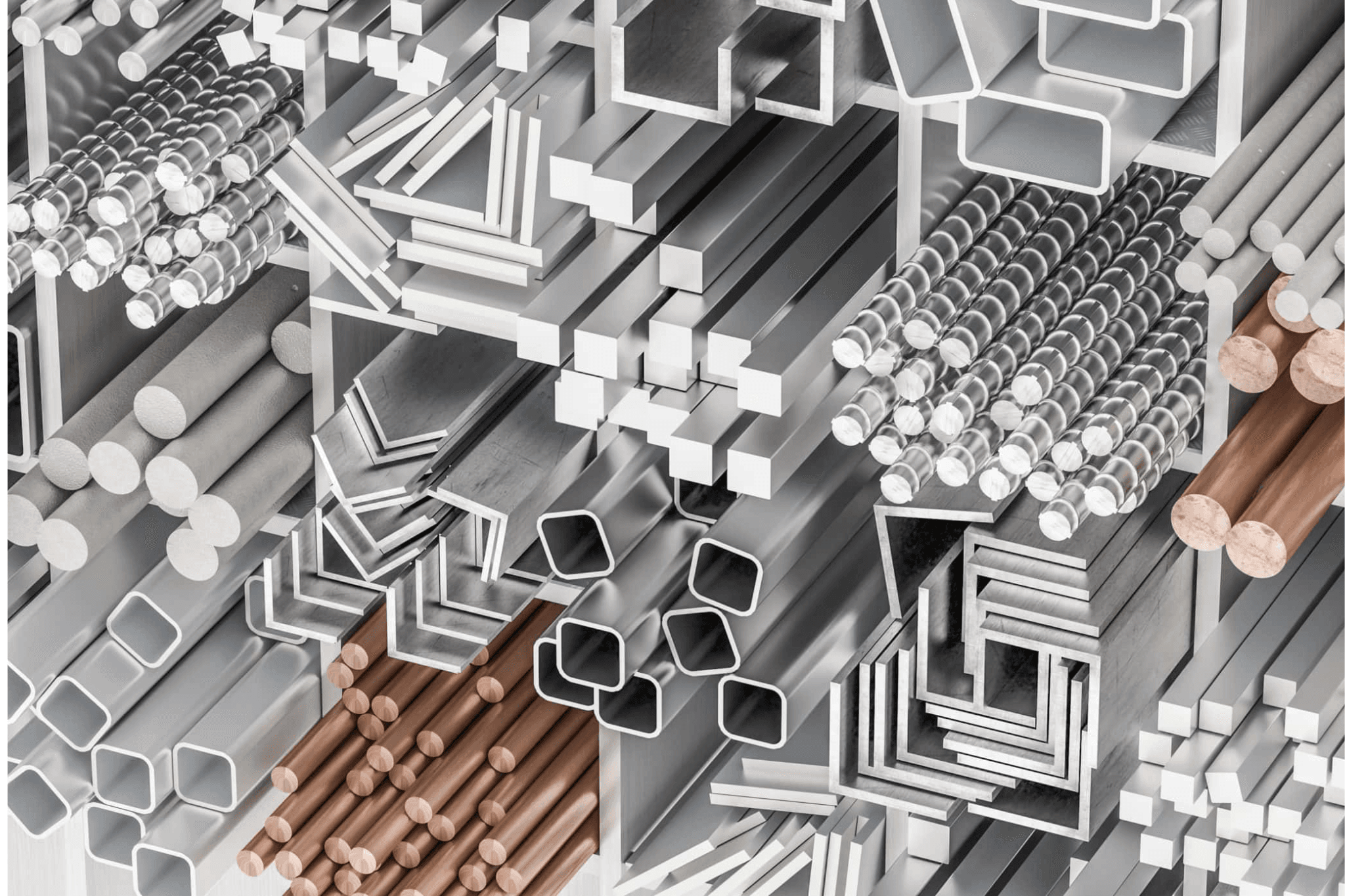

제조용 재료

프로토타입 제작과 대량 생산에 모두 적합한 수백 가지의 상업용 플라스틱, 금속, 엘라스토머 중에서 선택하세요.

- 최소한의 허용오차와 정밀도를 보장합니다.

- 낭비를 줄이고 생산 속도를 높입니다.

- 알루미늄, 강철 등의 금속 가공에 적합합니다.

- 대량 생산 시 반복성이 보장됩니다.

신뢰받는

CNC 가공의 소재

CNC 가공은 광범위한 재료를 수용하는 매우 다재다능한 공정으로, 다양한 산업과 응용 분야에 적합합니다. CNC 가공에 사용되는 재료는 여러 범주로 분류할 수 있습니다. 각 재료는 고유한 이점을 제공하여 다양한 제조 요구 사항에 적합합니다. CNC 가공을 위한 재료 선택은 강도, 무게, 내열성 및 완제품의 특정 요구 사항과 같은 요인에 따라 달라집니다.

CNC 가공을 살펴보세요: 밀링과 터닝에서 프로토타입 제작과 생산까지. 설계 최적화, 허용 오차, 나사산, 소재 선택 등에 대한 팁을 제공하는 가이드를 다운로드하세요.

금속 CNC 가공

다양한 산업에 적용되는 CNC 가공용 광범위한 금속. 일회성 프로토타입과 최종 사용 맞춤형 부품에 모두 이상적입니다.

| 이름 | 설명 | 가격 | ||

|---|---|---|---|---|

|

알류미늄 | 높은 가공성과 연성이 우수함 강도 대 무게 비율. |

$ $ $ $ $ | 즉시 견적 받기 |

|

스테인리스 스틸 | 높은 인장강도, 부식에 강함 및 온도. |

$ $ $ $ $ | 즉시 견적 받기 |

|

연강 | 높은 가공성과 용접성, 높은 강성. | $ $ $ $ $ | 즉시 견적 받기 |

|

놋쇠 | 마찰이 적고 전기 전도성이 우수합니다. 황금색 외관 |

$ $ $ $ $ | 즉시 견적 받기 |

|

구리 | 열 및 전기 전도성이 우수합니다. | $ $ $ $ $ | 즉시 견적 받기 |

|

합금강 | 강도와 피로 저항성이 우수합니다. | $ $ $ $ $ | 즉시 견적 받기 |

|

공구강 | 경도와 강성이 높고 내마모성이 우수합니다. | $ $ $ $ $ | 즉시 견적 받기 |

|

티탄 | 강도 대 중량 비율이 우수하여 다음과 같은 용도로 사용됩니다. 항공우주, 자동차, 의료 산업. |

$ $ $ $ $ | 즉시 견적 받기 |

|

인코넬 | 튼튼하고 부식에 강한 니켈 합금입니다. | $ $ $ $ $ | 즉시 견적 받기 |

|

인바 | 매우 낮은 계수를 갖는 니켈 합금 열팽창. |

$ $ $ $ $ | 즉시 견적 받기 |

플라스틱 CNC 가공

다양한 산업에 적용되는 CNC 가공용 플라스틱의 광범위한 범위. 일회성 프로토타입과 최종 사용 맞춤형 부품에 모두 이상적입니다.

| 이름 | 설명 | 가격 | ||

|---|---|---|---|---|

|

포엠(POM) | 고강성, 고정밀, 저마찰, 간편함 기계로. |

$ $ $ $ $ | 즉시 견적 받기 |

|

나일론 | 우수한 기계적 성질, 내열성, 화학물질과 마모에 대한 저항성이 뛰어납니다. |

$ $ $ $ $ | 즉시 견적 받기 |

|

ABS | 일반 열가소성, 충격에 강하고 가공이 쉬움 기계로. |

$ $ $ $ $ | 즉시 견적 받기 |

|

몰래 엿보다 | 고강도 열가소성 플라스틱으로 높은 내성을 가지고 있습니다 온도와 화학물질 노출. |

$ $ $ $ $ | 즉시 견적 받기 |

|

PTFE | 마찰이 적고, 화학 및 열에 강함 영향. |

$ $ $ $ $ | 즉시 견적 받기 |

|

폴리카보네이트 | 고강도, 우수한 충격 저항성, 투명한. |

$ $ $ $ $ | 즉시 견적 받기 |

|

폴리에틸렌 | 강도 대 중량 비율이 우수하고 내구성이 뛰어납니다. 영향과 기상 조건. |

$ $ $ $ $ | 즉시 견적 받기 |

|

비닐 | 뛰어난 내화학성, 내후성, 강성도 우수합니다. | $ $ $ $ $ | 즉시 견적 받기 |

|

PMMA(아크릴) | 투명한 단단한 플라스틱으로 종종 사용됩니다. 유리 대체물 |

$ $ $ $ $ | 즉시 견적 받기 |

|

애완 동물 | 뛰어난 내마모성을 갖춘 내구성 있는 플라스틱 높은 기계적 강도를 가지고 있습니다. |

$ $ $ $ $ | 즉시 견적 받기 |

|

폴리프로필렌 | 뛰어난 내화학성, 식품 등급 이용 가능한 옵션 |

$ $ $ $ $ | 즉시 견적 받기 |

|

지-10 | 강도가 높고, 수분흡수율이 낮아 우수함 전기 절연성, 내화학성 등이 뛰어납니다. |

$ $ $ $ $ | 즉시 견적 받기 |

|

FR4 | 난연성 유리 섬유 에폭시 라미네이트. | $ $ $ $ $ | 즉시 견적 받기 |

질문과 답변

Witcool은 CNC 가공 분야에서 풍부한 경험을 보유하고 있으며, 고객의 요구 사항을 정확히 충족하는 다양한 고품질 소재를 제공하여 모든 프로젝트에서 신뢰성, 품질 및 혁신을 보장합니다.

CNC 가공에 가장 일반적으로 사용되는 금속은 무엇입니까?

인기 있는 금속으로는 알루미늄(6061 및 7075), 스테인리스 스틸(316, 304), 황동, 구리가 있습니다. 이러한 소재는 강도, 내구성, 가공 용이성으로 인해 가치가 있습니다.

CNC 가공에서 재료 선택이 중요한 이유는 무엇입니까?

재료는 제품의 기계적 특성, 내열성 및 비용을 결정합니다. 각 재료는 스테인리스 스틸의 내식성이나 알루미늄의 경량성과 같은 고유한 특성을 가지고 있습니다.

CNC 가공에 알루미늄을 사용하는 이점은 무엇입니까?

알루미늄은 가볍고, 가공하기 쉽고, 내구성이 뛰어납니다. 6061 및 7075와 같은 합금은 가공성과 오래 지속되는 특성으로 인해 인기가 있습니다.

스테인리스강을 가공할 때 어떤 어려움이 발생합니까?

스테인리스 강철의 경도는 기계 가공을 어렵게 만들 수 있으며, 도구 마모를 피하기 위해 더 강한 도구와 더 느린 가공이 필요합니다.

어떤 플라스틱이 CNC 가공에 가장 적합합니까?

인기 있는 플라스틱으로는 ABS, 아세탈, PEEK 등이 있으며, 이는 내화학성, 경량성, 가공 정밀도가 뛰어나서 높이 평가받고 있습니다.

CNC 가공을 위한 소재를 선택할 때 어떤 요소를 고려해야 합니까?

주요 요소로는 강도, 내열성, 비용, 양극 산화 처리나 코팅 등의 2차 공정과의 재료 적합성 등이 있습니다.