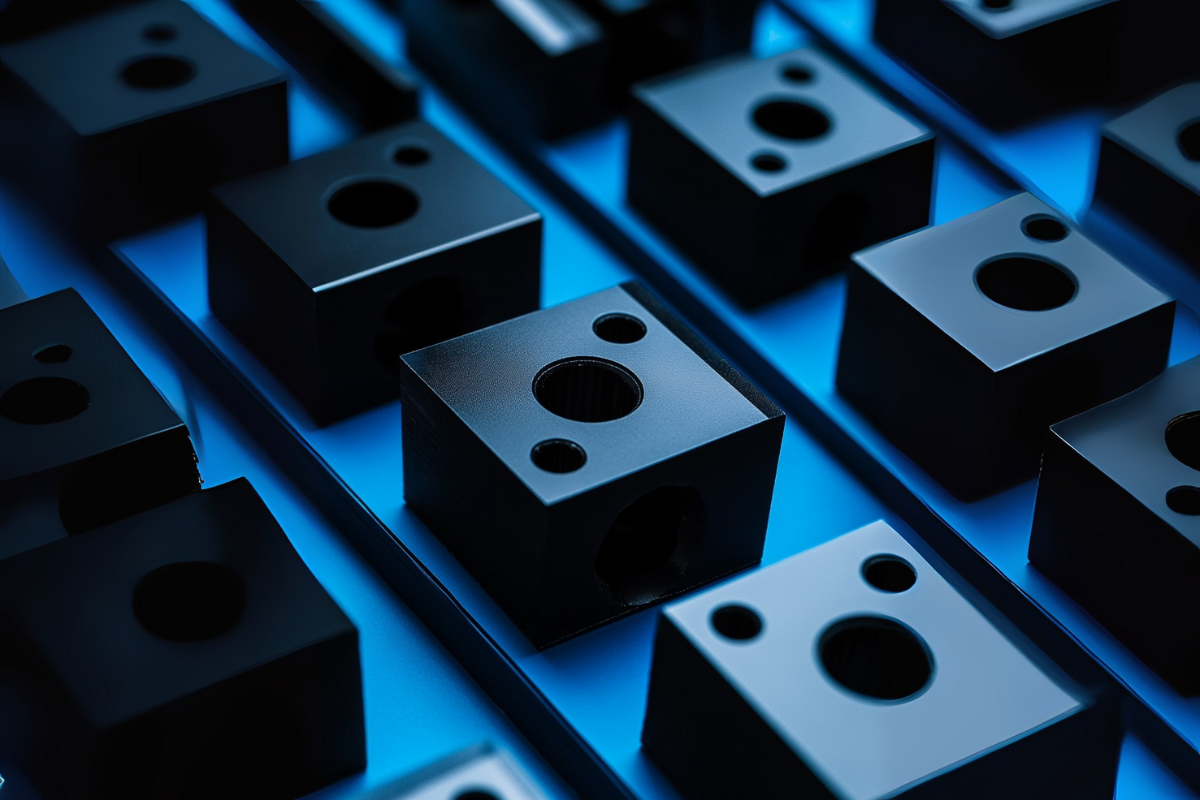

블랙 옥사이드 마감이란?

검은 산화물 마무리 손질 강철 및 기타 철 금속에 널리 사용되는 화학 표면 처리법입니다. 부품의 치수를 크게 변화시키지 않으면서 매끄럽고 검은색의 내식성 층을 형성합니다. 제조 분야에서 널리 사용되는 흑색 산화물은 기능적 특성과 미적 특성 모두에서 높은 평가를 받고 있습니다.

유형 및 프로세스 단계

유형:

- 뜨거운 검은 산화물: NaOH와 질산염을 사용하여 약 141 °C에서 욕조를 만듭니다. 자철광층을 형성하고 오일 밀봉이 필요합니다.

- 중간 온도: 온도가 낮고, 연기가 적으며, 화학적 성질과 결과가 비슷합니다.

- 차가운 검은 산화물: 실제 산화물보다는 구리 셀레나이드를 증착하는 실온 공정; 취미가들에게는 더 쉽지만 내구성이 떨어짐

프로세스 단계:

그만큼 블랙옥사이드 공정 강철 부품을 일련의 화학 용액에 담그는 과정이 포함됩니다. 일반적인 작업 흐름은 다음과 같습니다.

- 청소: 부품을 철저히 세척하여 기름, 녹, 이물질을 제거합니다.

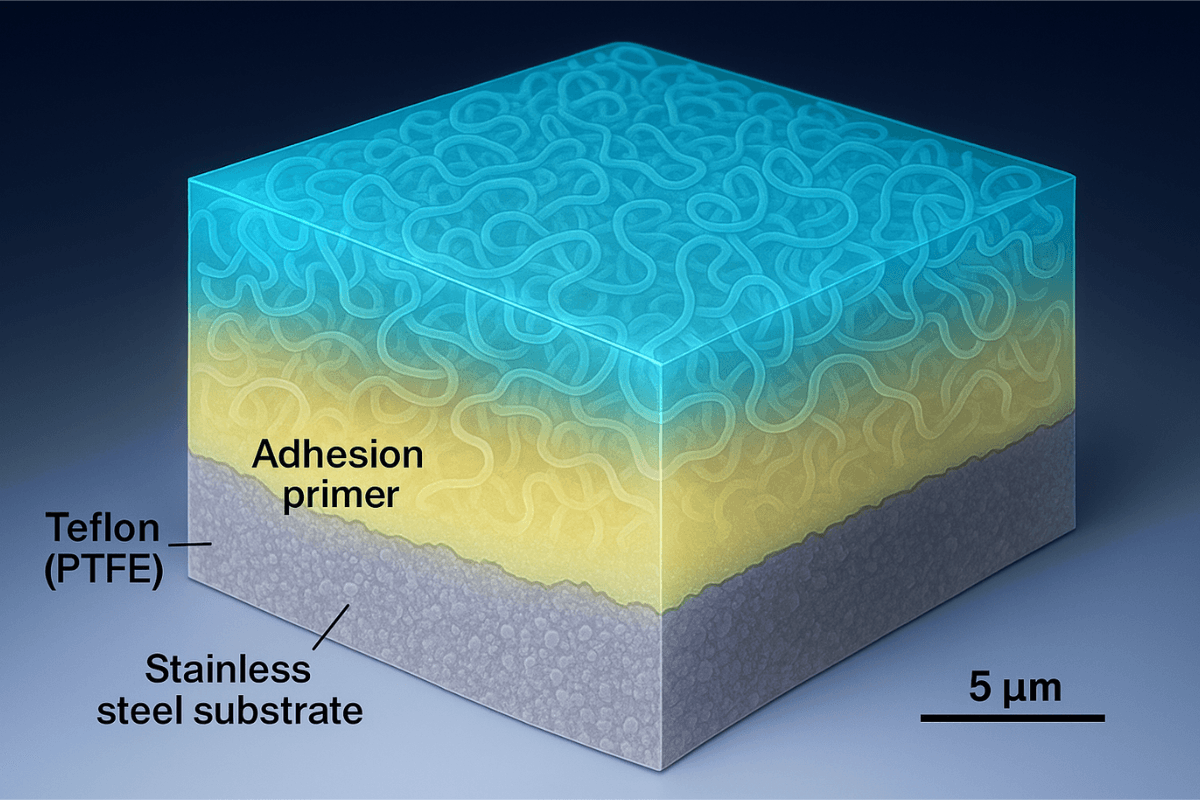

- 검게 변함: 세척된 부품을 산화염이 포함된 뜨거운 알칼리 용액에 담급니다. 이 반응으로 강철 표면에 자철광(Fe₃O₄) 층이 형성됩니다.

- 헹구기: 화학 물질을 제거하기 위해 부품을 헹굽니다.

- 밀봉: 실런트(종종 오일이나 왁스)를 발라 부식 저항성을 높입니다.

강철용 블랙옥사이드의 주요 이점

부식 저항성: 검은 산화층은 특히 오일로 밀봉했을 때 녹에 대한 적당한 보호 기능을 제공합니다.

개선된 외관: 부품에 균일하고 무광택의 검은색 마감을 주어 눈부심을 줄이고 미적 감각을 향상시킵니다.

차원 안정성: 코팅은 매우 얇아서(0.5~2.5마이크론) 엄격한 허용 오차를 유지합니다.

비용 효율성: 도금이나 페인팅보다 비용이 저렴하며, 특히 대량 생산 시에 유용합니다.

매끄러움: 움직이는 부분의 마찰을 줄입니다.

산업용 응용 분야

강철용 블랙 산화물 마감 다음에서 사용됩니다:

- 자동차: 패스너, 엔진 부품, 브라켓

- 항공우주 및 정밀공학: 기어, 베어링, 고내구성 부품

- 총기 및 도구: 총기 부품, 렌치, 하드웨어, 수술 도구

- 기계 부품 및 전자 제품: 조명기구, 스위치, 전기공구

다른 금속 마감 방법과의 비교

| 방법 | 두께 | 부식 저항성 | 모습 | 비용 |

|---|---|---|---|---|

| 검은 산화물 | ≤ 2마이크로미터 | 중간(밀폐 시) | 매트 블랙 | 낮은 |

| 아연 도금 | 더 두껍다 | 더 나은 | 밝은 금속성 | 중간 |

| 파우더 코팅 | 두꺼운 | 훌륭한 | 넓은 색상 범위 | 더 높은 |

| 아노다이징(알루미늄) | 얇음~중간 | 높은 (절연) | 다양한 색상 | 중간~높음 |

자주 묻는 질문

질문: 블랙 산화물 마감은 모든 금속에 적용 가능한가요?

A: 흑색 산화물은 주로 철 금속(강철, 철)에 사용됩니다. 스테인리스강, 구리, 아연에는 특수 공정이 필요합니다.

질문: 블랙옥사이드 코팅은 얼마나 내구성이 있나요?

답변: 특히 오일을 칠했을 때 적당한 마모 및 부식 방지 기능을 제공하지만 두꺼운 코팅만큼 견고하지는 않습니다.

질문: 검은색 산화물 코팅된 부품은 어떻게 관리해야 합니까?

A: 흑색 산화물 부품은 내식성을 유지하기 위해 정기적으로 오일이나 왁스를 발라야 합니다. 보호층을 벗겨내고 효과를 저하시킬 수 있는 강한 세척제나 연마제는 사용하지 마십시오.

질문: 검은 산화물을 비철금속에도 적용할 수 있나요?

네. 스테인리스 스틸, 구리, 아연, 심지어 분말 금속까지도 맞춤형 공정을 통해 흑화할 수 있습니다. 냉간 가공에서는 자철광 대신 구리-셀레나이드를 사용하는 경우가 많습니다.

질문: 검은 산화 마감 처리가 강철 부품의 기계적 특성에 영향을 미칩니까?

A: 아니요, 흑색 산화 피막 처리는 강도나 경도와 같은 강철의 기계적 특성에 큰 영향을 미치지 않습니다. 이는 매우 얇은 표면 처리로, 기본 소재를 변형시키지 않고 외관과 내식성을 주로 향상시킵니다.

질문: 블랙옥사이드 마감은 환경 친화적인가요?

A: 블랙 옥사이드 마감에는 취급 및 폐기 시 주의가 필요한 화학 물질을 사용하지만, 많은 현대식 시설에서는 엄격한 환경 및 안전 규정을 준수합니다. 환경 영향을 줄이기 위해 일부 공정이 개발되었으므로, 친환경적인 관행을 따르는 평판 좋은 업체를 항상 선택하세요.

결론 및 추가 자료

강철용 흑색 산화 피막은 외관을 개선하고 눈부심을 줄이며 부식 방지 기능을 제공하는 효율적인 방법입니다. 얇고 비용 효율적인 코팅은 다양한 산업용 부품에 적합합니다. 맞춤형 흑색 산화 피막 솔루션을 원하시거나 서비스에 대해 자세히 알아보시려면 문의하기 또는 저희를 방문하세요 강철 표면 처리 카테고리.