信頼できるCNC加工品質管理

ISO 認定のプロセス、厳格な検査、高度な精密ツールにより、CNC 機械加工部品のあらゆる部分で一貫した品質を確保する方法をご覧ください。

- 最終製品承認率 ≥ 98%

- 納期遵守率 ≥ 95%

- 顧客満足度 ≥ 95%

信頼される

17年の経験

CNC部品加工

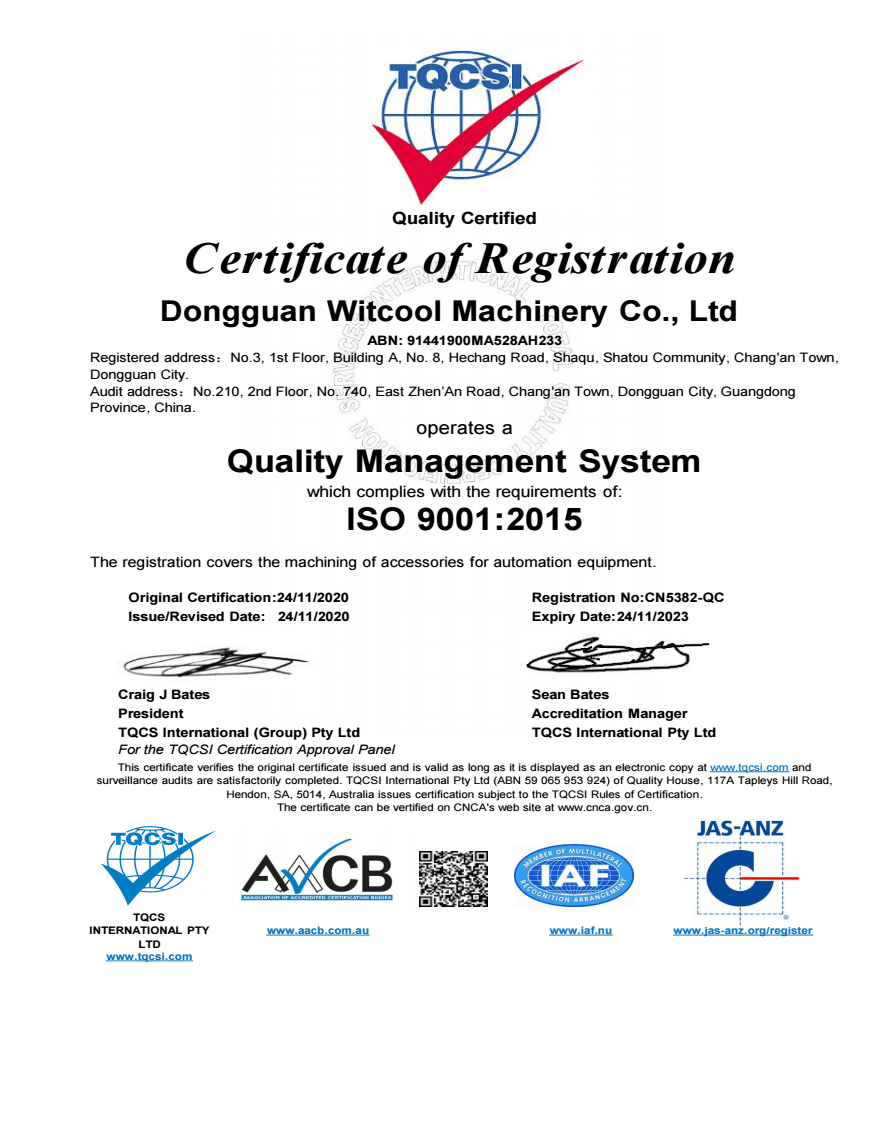

Witcool は、世界品質基準 ISO9001:2015 認証を取得しており、生産においては品質管理システムを厳格に遵守しています。

当社の品質管理チームは、すべての顧客の要件を満たすために、材料の品質、処理管理、出荷品質管理の確保に専念しています。当社は、品質管理と製品品質の継続的な改善に注力しています。

カスタム製造における卓越性

Witcool は、CNC 加工、ラピッドプロトタイピング、クイックツール作成など、試作から大量生産までカスタム製造のあらゆる側面にわたって継続的な改善と最適化に取り組んでいます。

当社はISO 9001:2015品質管理システムを厳格に遵守し、標準化された製造手順を適用し、高度な試験設備を活用しています。製造プロセスの各段階で綿密な測定と検査を実施し、お客様のプロジェクトが最高の品質基準を満たしていることを保証します。

当社の品質方針

高度な製造方法、厳格な品質管理、厳格な基準により、精度と耐久性が保証されます。

科学的管理法: 標準化されたプロセス、専門能力開発、効率性の向上、ベストプラクティスの実装。

リーン生産方式: 顧客志向の生産、プロセスの最適化、コスト管理、サプライチェーンの改善。

品質と効率: 品質管理の強化、コミュニケーションの改善、従業員のトレーニングにより、高品質の製品を提供します。

イノベーションと開発: 継続的な学習、知識管理、イノベーションのサポート、企業の結束の強化を促進します。

CNC加工における許容誤差

Witcool は、高度な CNC マシンを使用して、部品の加工において高い精度を確保しています。最大 ±0.005 mm の許容範囲を実現し、偏差が最小限で優れた精度の部品を製造できます。

| アイコン | 標準 | 許容範囲 | アイコン | 標準 | 許容範囲 | |

|---|---|---|---|---|---|---|

| 共通の許容範囲 | 0.0004" (±10μm / ±0.01mm) | 直径公差 | 0.00004" (±1μm / ±0.001мм) | |||

| 平坦性 | 0.00004インチ(2μm / 0.002mm) | 真っ直ぐさ | 0.00004" (1μm / 0.001mm) | |||

| 垂直性 | 0.0002" (5μm / 0.005mm) | 並列処理 | 0.0001" (2.5μм / 0.0025мм) | |||

| 丸み | 0.0002" (5μm / 0.005mm) | 同心 | 0.00002" (0.5μм / 0.0005мм) | |||

| 円筒度 | 0.0002" (5μm / 0.005mm) | 対称 | 0.0003" (8μm / 0.008mm) | |||

|

|

円形ランアウト | 0.00004" (1μm / 0.001mm) | 位置許容度 | 0.005ミリメートル |

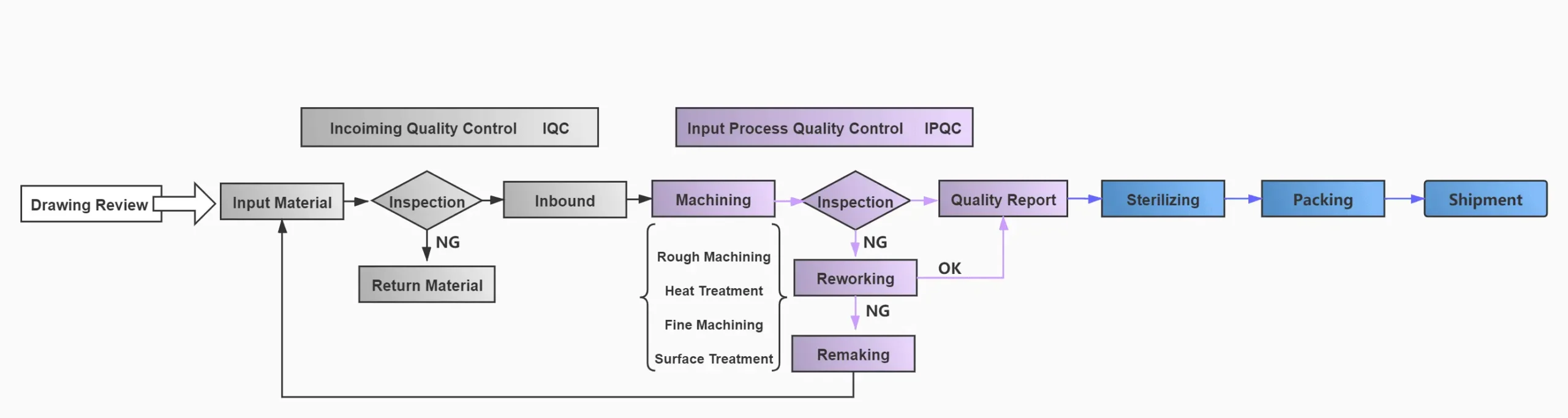

当社の品質管理フロー

Witcool では、厳格な品質管理プロセスにより、設計から最終製品に至るまで精度を保証します。

検査機器

当社の生産施設には最新の検査設備が備えられており、製造のあらゆる段階で精密な品質チェックが可能です。これにより、すべての部品がお客様の要件と業界基準を厳密に満たすことが保証されます。

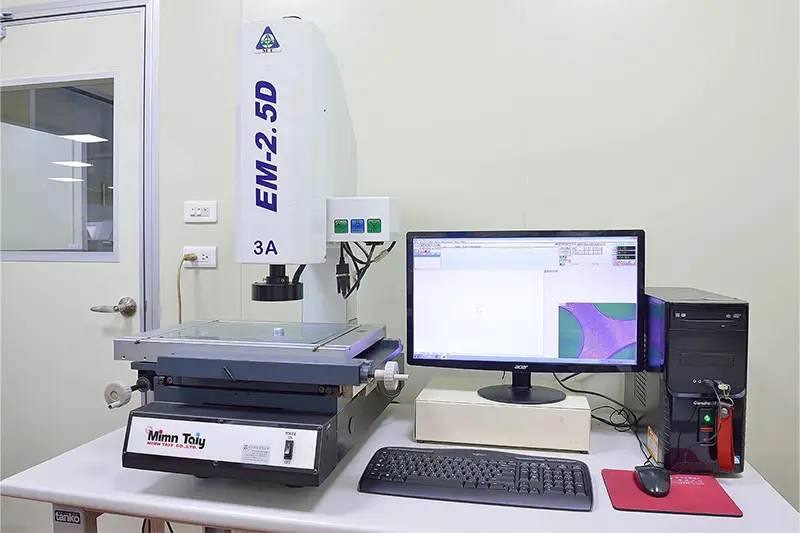

2.5D CMM

機械加工部品の寸法と幾何公差をチェックし、機械加工精度が指定された要件を満たしていることを確認するために使用されます。

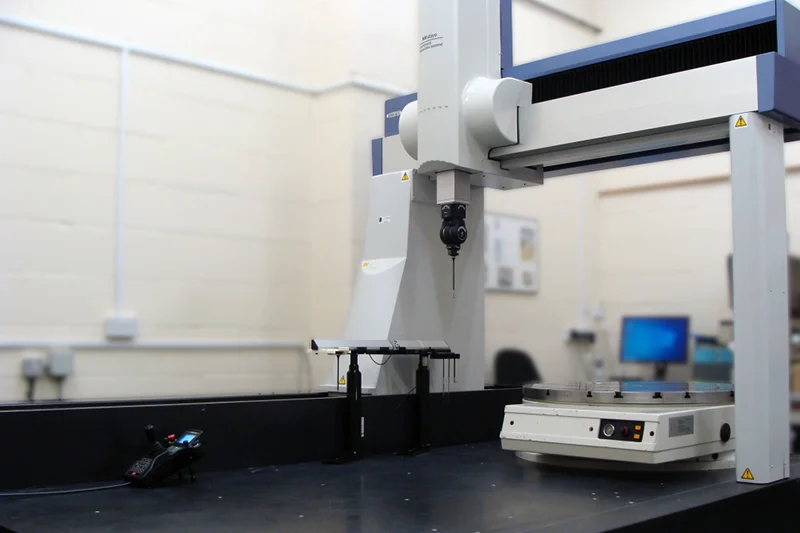

座標測定機(CMM)

寸法と座標の正確な 3 次元測定を提供し、部品が設計図面に準拠していることを保証します。

光学測定機

複雑な形状や表面の非接触測定に使用され、幾何学的な精度と制御を保証します。

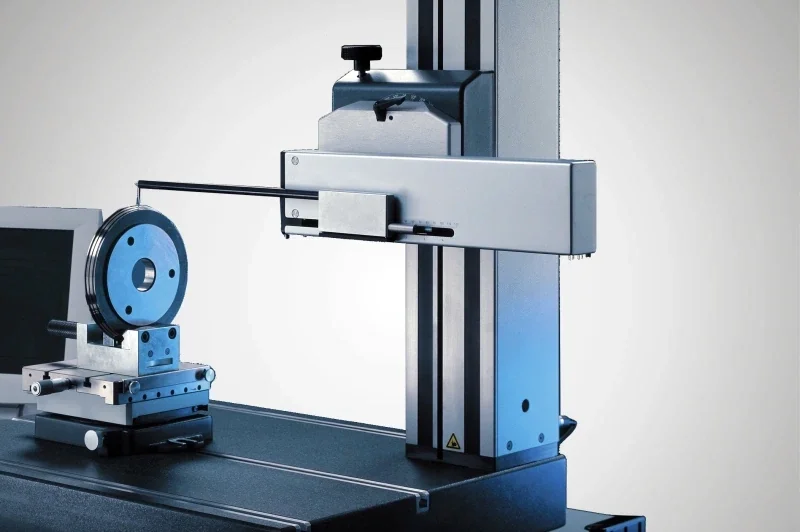

輪郭測定機

部品のプロファイルと輪郭を検査し、設計要件と標準への準拠を確認するのに役立ちます。

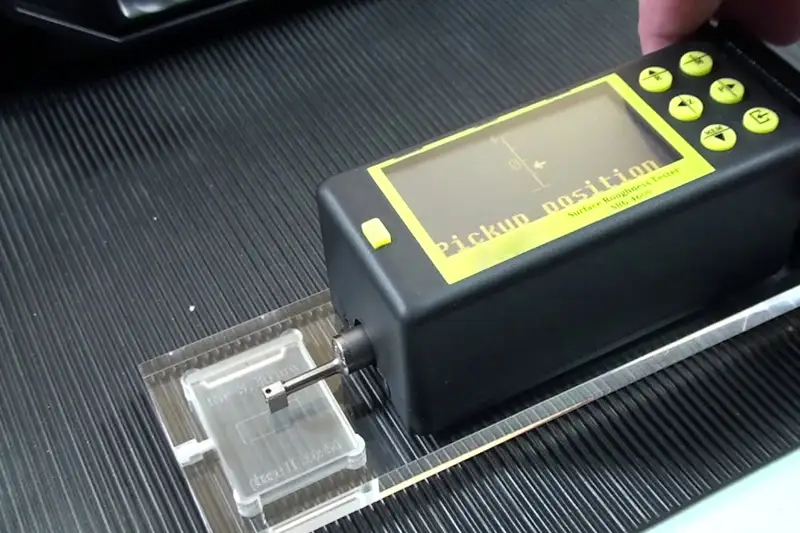

表面粗さ試験機

部品の機能性と耐久性に重要な粗さを測定することで表面品質を評価します。

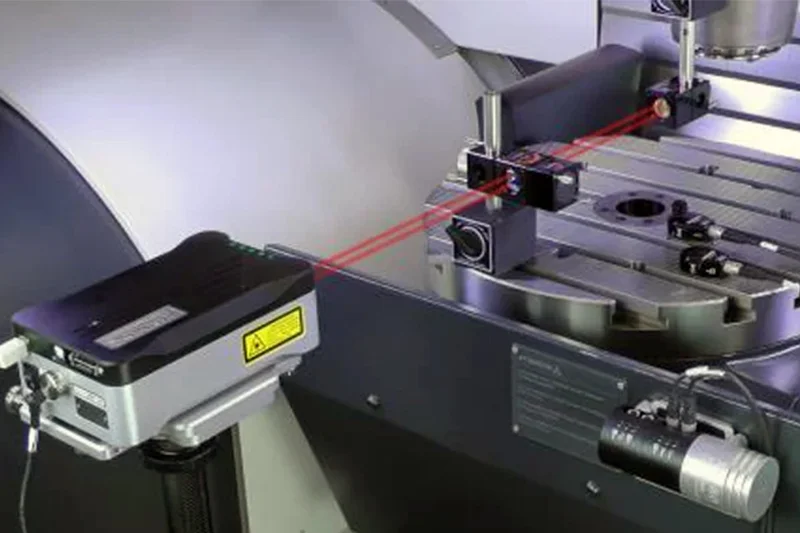

レーザー干渉計

高精度レーザー測定を使用して、幾何学的パラメータと部品の位置合わせの精度を監視します。

高さゲージ

通常は定盤と組み合わせて、高さ、深さ、その他の部品の寸法を測定するために使用されます。

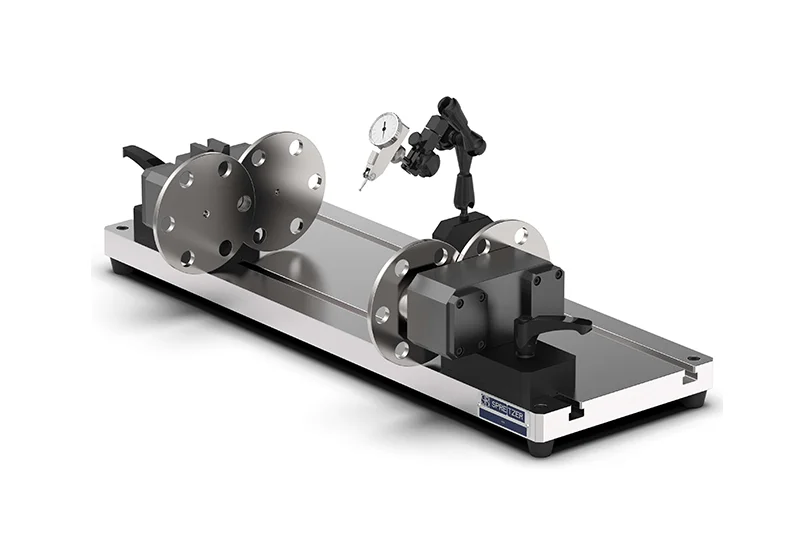

同心度試験機

穴またはシャフトの同心度を測定して、機械システムの適切な位置合わせと機能を確認します。

コーティング厚さ計

耐久性と保護の基準に準拠するために、製造中または修理中にコーティングの厚さを制御します。

硬度計

材料の硬度を測定し、機械的なストレスや摩耗に対する耐性を判断するのに役立ちます。

当社の品質ドキュメント

Witcoolは、カスタムパーツが最高の製造基準を満たすよう、厳格な手順を踏んでいます。ご要望に応じて、証明書やレポートもご提供いたします。以下の品質証明書は、CNC加工、板金加工、3Dプリント、ダイカストなど、当社のすべての製造技術に適用されます。

座標測定機(CMM)検査レポート

座標測定機を使用して正確な測定を行い、製品が指定された寸法を満たしているかどうかを確認します。

材料証明書(金属のみ)

金属の組成と品質を確認し、材料が標準とトレーサビリティの要件を満たしていることを確認します。

標準測定プロトコル

校正されたツールを使用し、指定された精度と許容範囲の要件を遵守することで、測定の精度と一貫性を保証します。

初回物品検査報告書(FAIR)

すべての設計および契約要件への準拠を確認するための最初の生産サンプルの詳細な検査が含まれます。

RoHS証明書

EU RoHS 指令への準拠を検証し、製品に有害物質が含まれず、安全規制を満たしていることを確認します。

REACHコンプライアンス証明書

EU REACH 規則への準拠を確認し、化学物質の安全な管理と環境基準の遵守を保証します。

適合証明書

製品が要件と図面に指定されているすべての必要な品質および安全基準を満たしていることを証明します。

継続的な改善

Witcoolでは、品質と効率性の継続的な向上が競争力維持の鍵であると考えています。そのため、以下の2つの中核分野における継続的な改善と最適化に取り組んでいます。

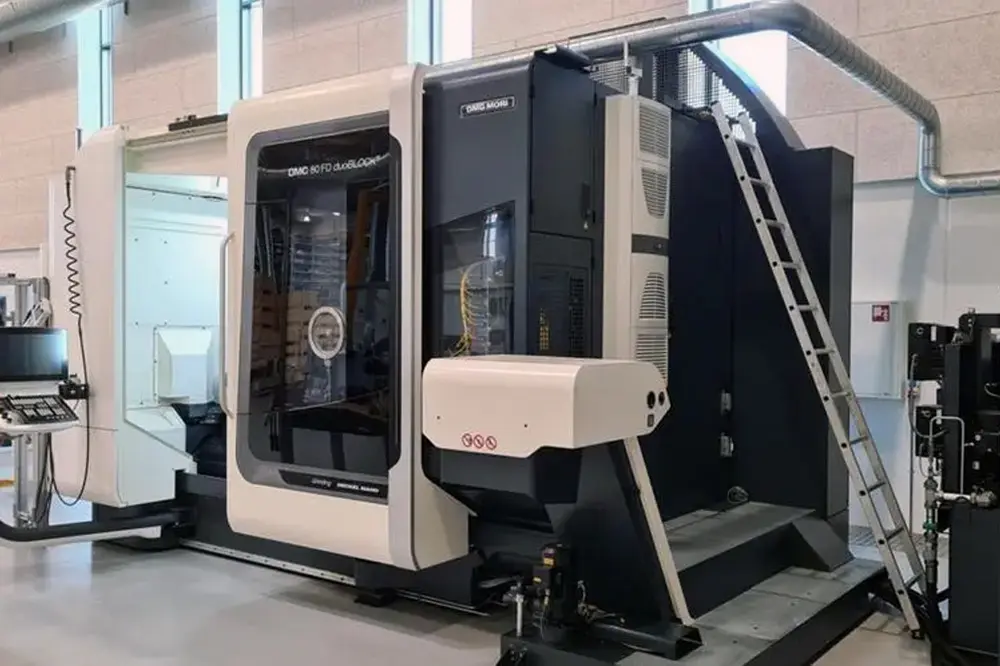

先進的な設備と技術の導入

当社では、製造プロセスが常に業界の最新技術に合致するよう、2年ごとに最先端の設備とCNC加工技術を評価し、導入しています。これらのアップグレードは、生産効率の向上だけでなく、製品の精度と品質を大幅に向上させます。例えば、最近ではスイス製の最新鋭5軸加工センターを導入し、複雑な部品の加工能力を大幅に向上させました。

従業員の研修と開発

チームの知識とスキルを常に最新の状態に保つため、3ヶ月ごとに社内研修を実施し、少なくとも年に2回は外部の専門家を招いて技術交流を行っています。さらに、中国機械工程学会(CMES)や中国機械工業協会(CMMA)などの業界団体が主催する研修プログラムにも積極的に参加しています。これらの取り組みにより、スタッフは最新の業界動向を把握し、実践的な課題解決能力を向上させることができます。

質問と回答

Witcoolでは、CNC加工プロセスのあらゆる段階を厳格に管理し、高い製品品質と精度を確保しています。標準規格を遵守し、革新的な技術を導入することで、あらゆるプロジェクトの品質向上に貢献する信頼性の高いソリューションを提供しています。

CNC 加工において品質管理が重要なのはなぜですか?

品質管理は、製品が定められた基準を満たしていることを保証し、欠陥を防止し、顧客満足度を維持し、製造プロセス全体の信頼性をサポートします。

CNC 加工における重要な品質管理パラメータは何ですか?

主なパラメータには、寸法精度、公差、表面仕上げ、材料の完全性などが含まれます。これらを遵守することは、機械加工部品の機能性にとって不可欠です。

CNC加工では品質検査はどのように行われますか?

Witcool では、品質検査に寸法測定、材料分析、CMM や光学システムなどの高度な検査機器の使用が含まれ、仕様への準拠を検証します。

熟練したオペレーターは品質の確保にどのような役割を果たすのでしょうか?

当社の熟練したオペレーターは、自動化システムが見逃す可能性のある微妙な点を検出し、最適な機械パフォーマンスと潜在的な問題の早期発見を保証します。

CNC 加工中にクライアントの機密性をどのように保証できますか?

Witcool は、安全なファイル転送や秘密保持契約 (NDA) などの厳格なプロトコルを適用して機密性を最優先し、お客様のデザインを保護します。

CNC 加工部品に品質上の問題が見つかった場合はどうなりますか?

品質問題が判明した場合は、生産を停止し、根本原因を調査し、再発防止のための是正措置を実施します。遅延や問題が発生した場合は、速やかにお客様にご連絡いたします。