YTOTにおけるグローバル光学レンズイノベーション

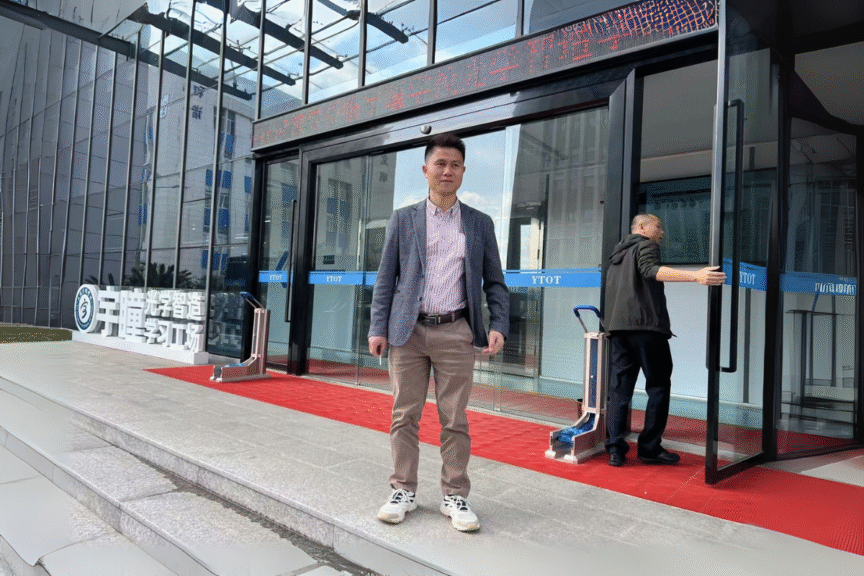

最近、ウィットクール・マシナリーのチームは、 YTOT、世界有数の光学レンズメーカーです。 グローバル光学レンズイノベーション YTOTの光学レンズ製造における画期的なアプローチの中核を成すのが、この技術です。この特別ツアーでは、視覚技術の未来を牽引する先進技術、精密エンジニアリング、そして創造的なプロセスを深く掘り下げます。

CNC 加工サービス プロバイダーとして、当社はサプライ チェーンにおける精度と信頼性の重要性を理解しています。これは、特に光学レンズ製造の分野において、YTOT が高度なレンズ製造において明確に共有している価値観です。

製造業の卓越性に関する会議

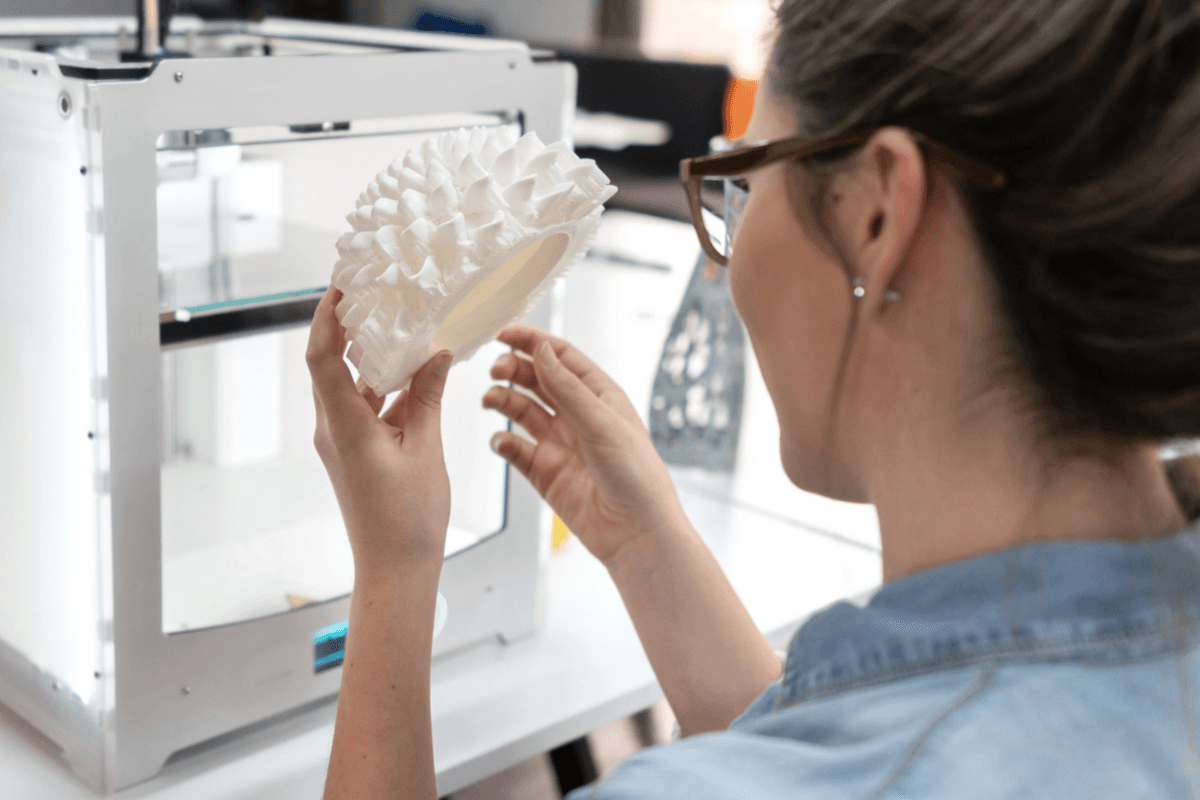

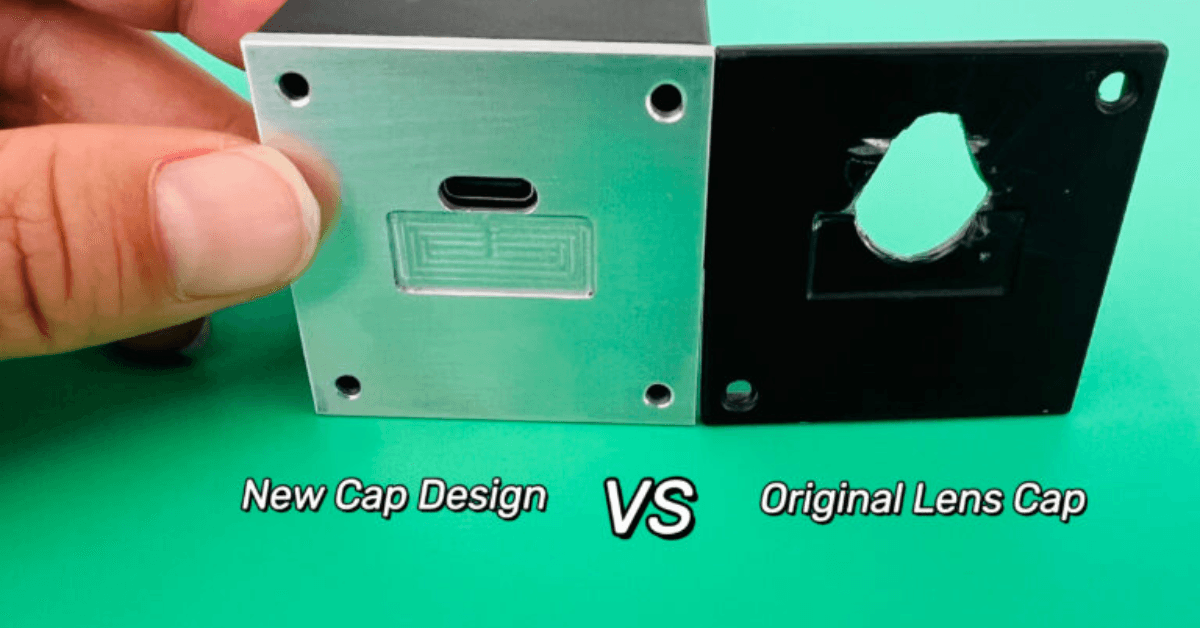

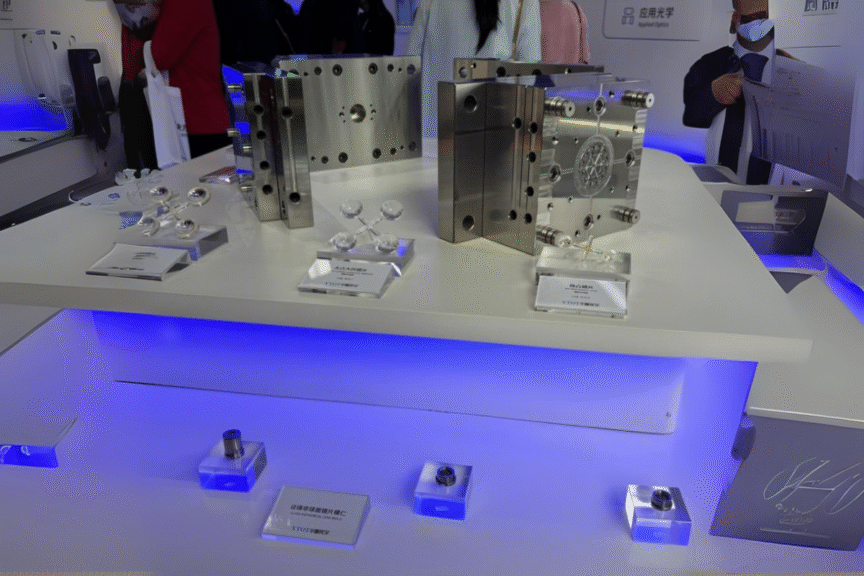

YTOTの最先端施設では、光学レンズ製造におけるイノベーションが、高品質なカスタム加工部品といかに密接に結びついているかを目の当たりにしました。自動化された組立ラインから綿密に管理されたクリーンルームまで、YTOTの工程のあらゆる段階は、卓越した光学的透明性と性能を実現するために設計されています。彼らの成功は、レンズ設計だけでなく、あらゆる機械部品の精度にも左右されることを目の当たりにし、感銘を受けました。多くの部品は、 CNC加工光学レンズ製造における専門知識を強調しました。

Witcoolが光学リーダーをどのようにサポートしているか

今回の訪問で、サプライチェーン全体にわたる強固なパートナーシップの重要性を再確認しました。Witcoolは、YTOTのような企業に対し、機器、工具、組立ライン向けの高精度部品の製造をカスタムCNC加工サービスで提供しています。厳しい公差、複雑な形状、そして多様な材料に関する専門知識を活かし、光学業界のお客様に最も厳しい要件を満たす部品をお届けしています。

共に未来を築く

CNC加工と光学レンズ製造の連携は、監視、自動車ビジョン、医療用画像処理、マシンビジョンといった分野における技術の進歩に不可欠です。WitcoolはYTOTのような革新的な企業と緊密に連携することで、部品だけでなく、世界的な品質基準に貢献する信頼性の高いソリューションを提供することで、両業界の進歩に貢献しています。

YTOTを去るにあたり、彼らの卓越性へのこだわりに感銘を受け、精密さとビジョンが真に融合する製造エコシステムの一員であることを誇りに思います。私たちは共に、完璧に機械加工された部品一つ、そして世界クラスのレンズ一つ一つを創り上げ、光学技術の未来を形作っていくことに貢献していきます。