イノベーションの課題に立ち向かう

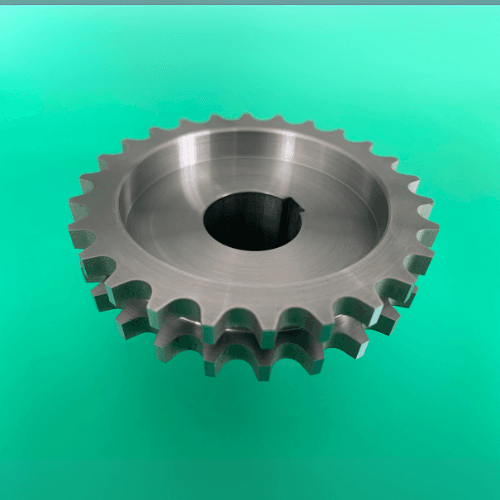

生産性の向上は包装業界では極めて重要であり、効果的な戦略の 1 つとして包装機械に CNC 部品を使用する方法があります。このケース スタディでは、高品質の CNC 部品を導入することで、業務を効率化し、ダウンタイムを削減し、全体的な生産性を向上させる方法を探ります。

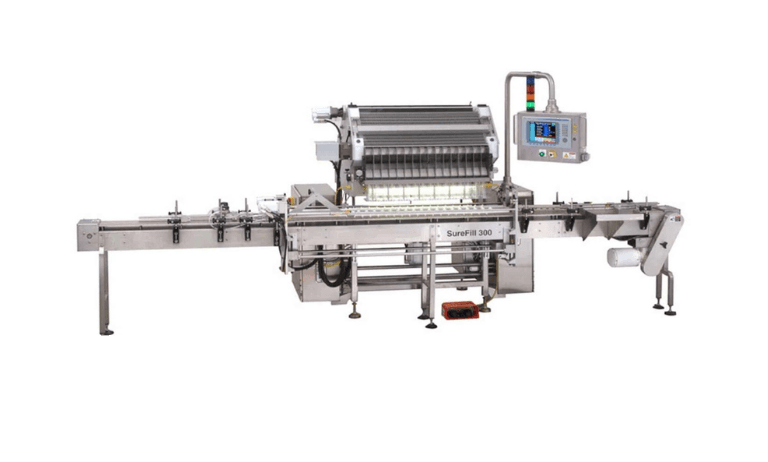

当社のクライアントの 1 社は、高速缶詰充填システムを設計する先進的な企業であり、競争の激しい包装機械市場で、複雑な設計を画期的な機械の要求を満たす実際の高品質部品に変換するという課題に直面していました。

正確な部品を作る

クライアントは、高い不良率と非協力的なベンダーと戦っていたが、当社と提携した。 CNC部品製造これにより、生産スケジュールが脅かされ、機械独自の速度の利点が損なわれる恐れがありました。当社のお客様が所有する機械は、従来の市場モデルを 5 倍上回る性能を実現し、効率基準を引き上げる設計でした。しかし、信頼できる部品がなければ、この山の頂上に到達することは不可能でした。

転機

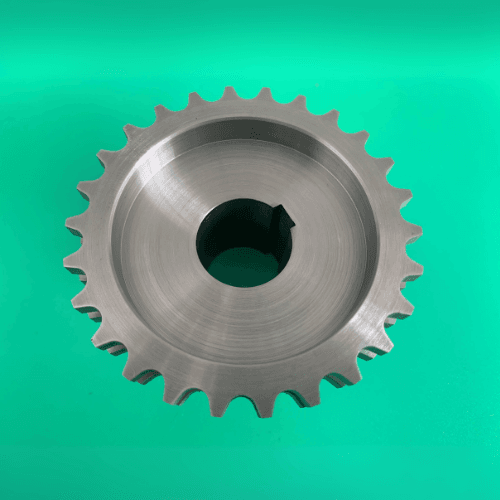

緊急性を認識し、当社はすぐに行動を起こしました。顧客は、変更された設計に合う新しい部品セットを要求しました。通常、サプライヤーは、この要求に困難な手順を踏むことになります。しかし、当社の戦略は独特でした。必要な原材料をすぐに入手し、生産機械を新しい要件に合わせて変更することで、部品を迅速に納品しました。

インパクトと印象

その結果、クライアントの生産効率が大幅に向上しました。組み立てとデバッグのプロセスを迅速化し、ダウンタイムを削減することで、クライアントの期待に応えるだけでなく、期待を上回る成果を上げました。コンポーネントの品質に満足していただけたことに加え、クライアントは、迅速かつ専門的にコミュニケーションを取り、問題を解決する当社の能力に特に感銘を受けました。

結論: 迅速かつ高品質なコラボレーション

このコラボレーションは、単なる取引のやり取りではなく、イノベーションと精密生産を組み合わせることで何が達成できるかを示すものです。当社はお客様と共にあり、お客様が高速梱包機で市場を席巻し続ける中、高品質の部品と迅速なサポートで障害を成功に変える準備ができています。

成功を視覚化する: プロセス図

当社のプロセスをさらにわかりやすくするために、次のマーメイド図では、お客様が生産上の障害に遭遇してから当社の支援を受けて効率性が飛躍的に向上するまでの過程を示しています。

グラフ LR A[クライアントの最初の課題] -->|最適ではない部品品質| B(欠陥の特定) B --> C[設計の更新が必要] C -->|当社に連絡| D[即時のサプライヤー対応] D --> E[迅速な材料調達] D -->|迅速な再設計| F[生産プロセスの適応] E --> G[強化された部品製造] F --> G G --> H[徹底した品質管理] H -->|部品の配送| I[クライアントによる機械の組み立て] I --> J[機械のデバッグとテスト] J -->|必要な速度の達成| K[生産効率の向上] K --> L[クライアントの満足度と市場の混乱]

この図は、クライアントとの迅速な対応とコミュニケーションにより、効率が向上し、プロジェクトが成功することを示しています。

パッケージングにおける CNC の未来

このケーススタディは、包装業界における精度と品質の重要性を強調しています。CNC 加工は、企業が生産能力を高め、高い品質基準を維持できるようにすることで、ゲームチェンジャーであることが証明されています。包装業界が進化し続けるにつれて、CNC 部品の役割は拡大すると予想され、競争力を維持するためにこの技術を採用する企業が増えています。

精度と進歩の分野における当社のストーリーは、単一のクライアントの達成で終わるものではありません。むしろ、品質とコラボレーションへの継続的な献身です。私たちは、先見の明のある人々がアイデアを実現するための推進力となります。CNC コンポーネント製造の専門家として、Witcool チームは機械加工のスキルだけでなく、イノベーションの核心を理解することにも長けています。

効果、品質、そして前進につながるコミュニケーションを重視するパートナーをお探しなら、当社がお手伝いします。

ご質問やご提案、あるいはお客様の取り組みの実現に当社がどのように貢献できるかについてのご相談などがありましたら、直接ご連絡ください。一緒に創造し、発明し、成長しましょう。

今すぐご連絡ください!