CNC加工サービス

- 最小注文数量なし、1個から5000個以上まで

- ISO 9001: 2015 認証取得

- 許容誤差は±0.005mmと非常に狭い

- 最短1日のリードタイム

信頼による

オンデマンド製造

即時の価格設定、プロジェクトのリードタイム、

および DFM フィードバック。

- *アップロードはすべて安全かつ機密に保たれます。

*デザインファイルをお送りいただく場合は、 ヴィヴィアン

プロフェッショナルチーム

Witcool は、製造プロセスを熟知したプロフェッショナルなチームです。

最高品質

Witcool は ISO 9001:2015 監査に合格し、常に品質第一の原則に従っています。

迅速な配達

各種精密金属部品を短期間で製造することができました。

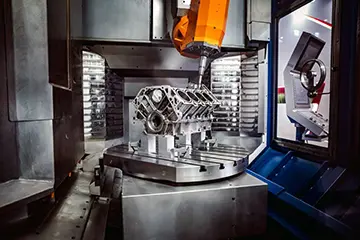

当社のCNC加工サービス

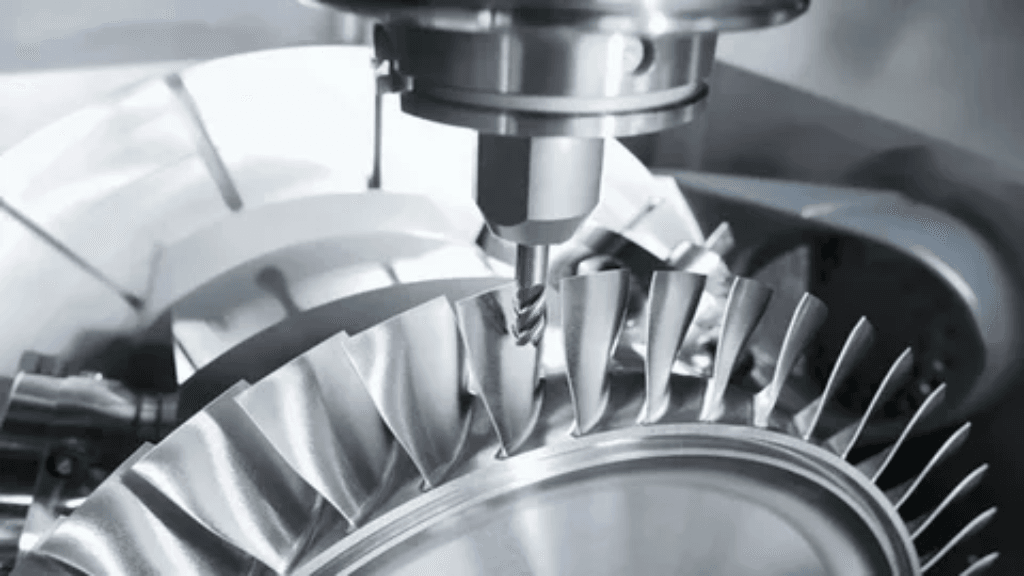

5軸CNC加工

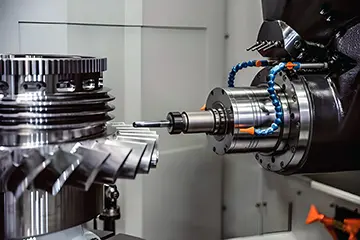

CNCフライス加工

迅速なプロトタイプや生産部品のためのオンデマンドCNCフライス加工。金属やプラスチックからカスタムフライス加工。 0.01 mmの許容範囲部品はすぐに準備できます 1日.

CNC旋削

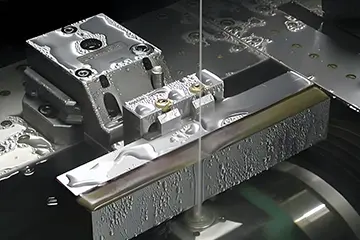

ワイヤー放電加工

カスタム CNC 加工サービスに Witcool を選ぶ理由

Witcool は、カスタム オンライン CNC 加工サービスにおいて多くの利点を提供します。当社の最先端の設備は、あらゆるプロジェクトで優れた精度と品質を保証します。当社のオンライン プラットフォームはユーザー フレンドリーで、アイデアをアップロードし、材料を選択し、すぐに見積もりを取得できます。

弊社の経験豊富なエンジニア チームが、プロセス全体を通じてお客様をサポートし、ガイドいたします。お客様のニーズを満たすために、プラスチックや金属など、幅広い材料を取り揃えています。確実な納期と迅速な対応により、生産スケジュールの整合性を維持できます。

当社はコスト効率よりも品質を優先しているため、小規模プロジェクトにも大規模プロジェクトにも適したサービスをご提供しています。当社は、お客様の満足と継続的な進歩に専心しているため、カスタムメイドの CNC 加工サービスにおいて信頼できる選択肢となっています。

厳しい許容範囲

厳しい許容差の CNC 加工は、狭い範囲で精度を維持するために不可欠です。これにより、一貫した品質、仕様の順守が保証され、特に航空宇宙、自動車、医療機器などの業界の複雑な部品の信頼性が向上します。

迅速なリードタイム

当社の CNC 加工サービスの短いリードタイムを活用すれば、プロジェクトを迅速に完了できます。当社の効率的なプロセスと高度な機械により、品質を損なうことなくタイムリーな納品が保証されます。当社にお任せいただければ、納期を守り、生産スケジュールをシームレスに維持できます。

迅速な対応能力

当社の CNC 加工サービスは、応答時間が速いことで知られています。当社は、高度な設備と熟練したオペレーターのおかげで、品質を犠牲にすることなく効率を優先しています。お客様のニーズに合わせた迅速かつ信頼性の高い製造ソリューションを当社にお任せください。

革新的なソリューション

CNC 加工では、革新的な問題解決には高度な方法を使用して課題に取り組みます。これには、ツール パスの最適化、適応戦略、予測メンテナンスが含まれます。これにより効率と精度が向上し、製造の生産性が向上します。

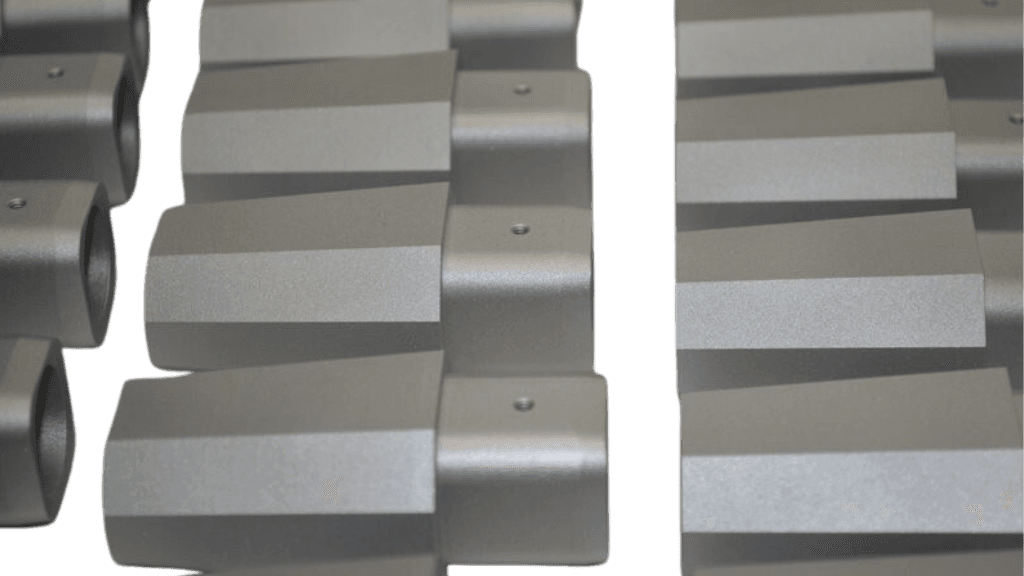

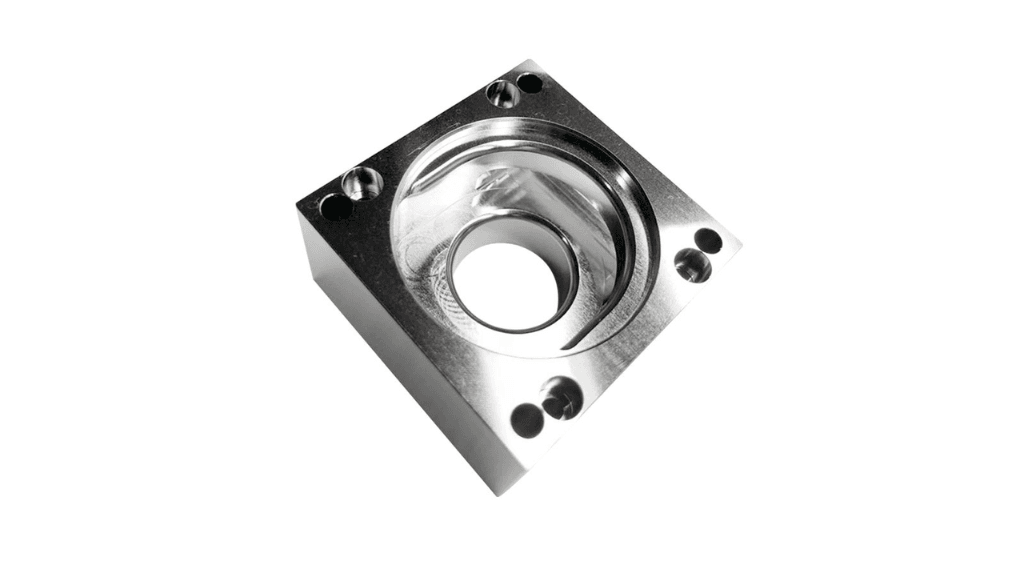

CNC加工部品のギャラリー

CNC加工とは

CNC 加工は、コンピュータ数値制御加工の略で、コンピュータ制御と機械設備によって駆動される製造技術です。加工では、ワークピースから特別に作成されたコンポーネントと部品を除去します。手作業による加工とは異なり、CNC 加工では、事前にプログラムされた一連のコマンドを使用して切削工具の動きと操作を制御するため、精度が確保されます。

この方法は、金属、ポリマー、木材、複合材など、幅広い材料に対して、並外れた精度、再現性、効率性を提供します。この方法は、対象部品のコンピュータ支援設計 (CAD) モデルの開発から始まり、その後、機械の動作とツール パスの指示を含む CNC プログラムに変換されます。CNC マシンは、加工中にこれらのプログラムされた指示に従い、対象物を正確に切断して、対象物を目的の最終形状に成形します。

航空宇宙、自動車、電子機器、医療、プロトタイプは、CNC 加工の適応性、スピード、厳しい許容誤差で高品質の部品を作成する能力により、CNC 加工が使用されている分野のほんの一部です。

CNC加工の利点

従来の技術と比較して、CNC 加工にはさまざまな利点があります。常に正確で精密な結果が保証されるため、ミスが少なくなります。プロセスの自動化、コストと製造時間の削減により、効率も向上します。CNC マシンで複雑なデザインや形状を簡単に処理できるため、新しい機会が生まれます。また、さまざまな材料で動作するため、適応性が向上します。優れた部品やコンポーネントを作成するために、CNC 加工は基本的に信頼性が高く、迅速で、手頃な価格の代替手段を提供します。

CNC加工アプリケーション

CNC 加工の柔軟性と精度により、幅広い分野で活用されています。航空宇宙分野では、タービン ブレードなどの複雑な部品の作成に利用されています。CNC 技術は、自動車製造においてエンジン部品や特殊部品の製造に使用されています。電子機器分野では、高精度の回路基板の製造に使用されています。CNC の精度は、医療用インプラントや手術器具の製造に役立っています。CNC マシンは、木工分野でも、洗練された家具デザインの作成に使用されています。これらの用途は、さまざまな業界の現代の製造において CNC 加工が重要な役割を果たしていることを示しています。

CNC加工材料

金属

アルミニウム

アルミニウムは、密度が低く、機械的特性に優れ、熱伝導性と電気伝導性が高く、耐腐食性があるため、機械加工に広く使用されています。アルミニウム合金材料は、その優れた特性により、主に航空宇宙、自動車、建設、海洋、電子機器、包装、医療、消費財業界で使用されています。

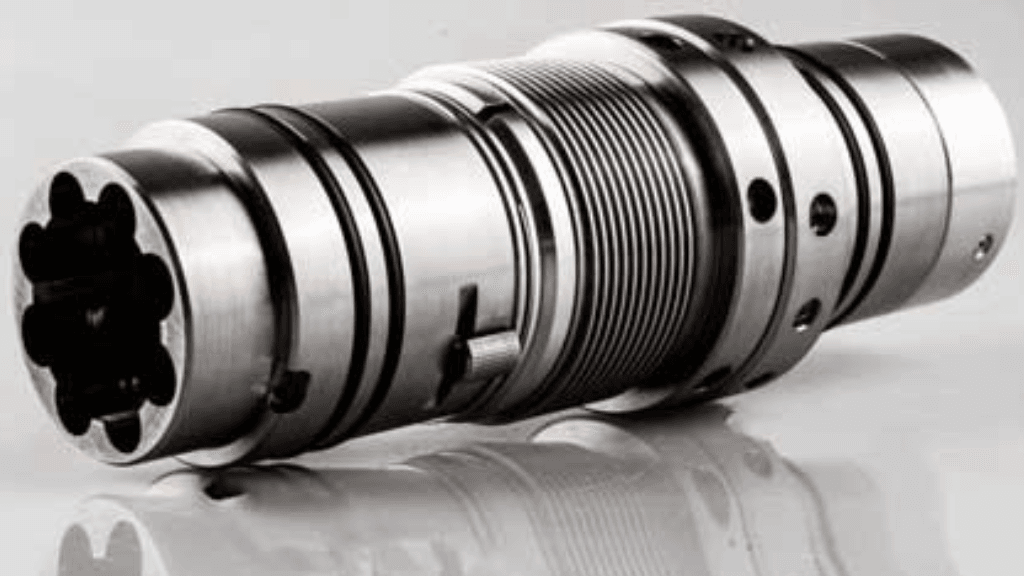

工具鋼

工具鋼は、高硬度、耐摩耗性、高温でも刃先を維持する能力を備えて設計されており、他の材料の切断や成形に最適です。工具や金型の製造によく使用される工具鋼には、通常、タングステン、モリブデン、クロム、バナジウムなどの元素が含まれています。これらの元素により硬度と耐熱性が向上し、他の金属の打ち抜き、押し出し、機械加工などの用途に適しています。

ステンレス鋼

ステンレス鋼は、優れた耐腐食性、強度、美観で知られています。キッチン用品、医療機器、自動車部品、建築資材など、幅広い用途で広く使用されています。

304 や 316 などのステンレス鋼合金は、耐久性、成形性、酸化や汚れに対する耐性のバランスが取れており、工業製品と消費者向け製品の両方に最適です。

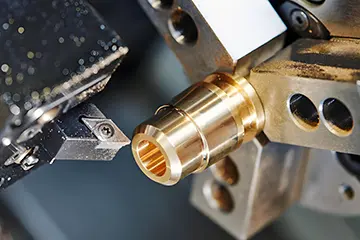

真鍮

真鍮は、機械加工性、耐腐食性、熱伝導性に優れています。明るい金のような外観のため、配管、電気用途、装飾品などによく使用されます。

銅

銅は電気伝導性と熱伝導性が高く評価されており、電気配線、電子機器、熱交換器に欠かせない素材です。また、耐腐食性と加工性にも優れています。

チタン

チタンは、高い強度対重量比、耐腐食性、生体適合性で知られています。航空宇宙、医療用インプラント、高性能アプリケーションで広く使用されています。

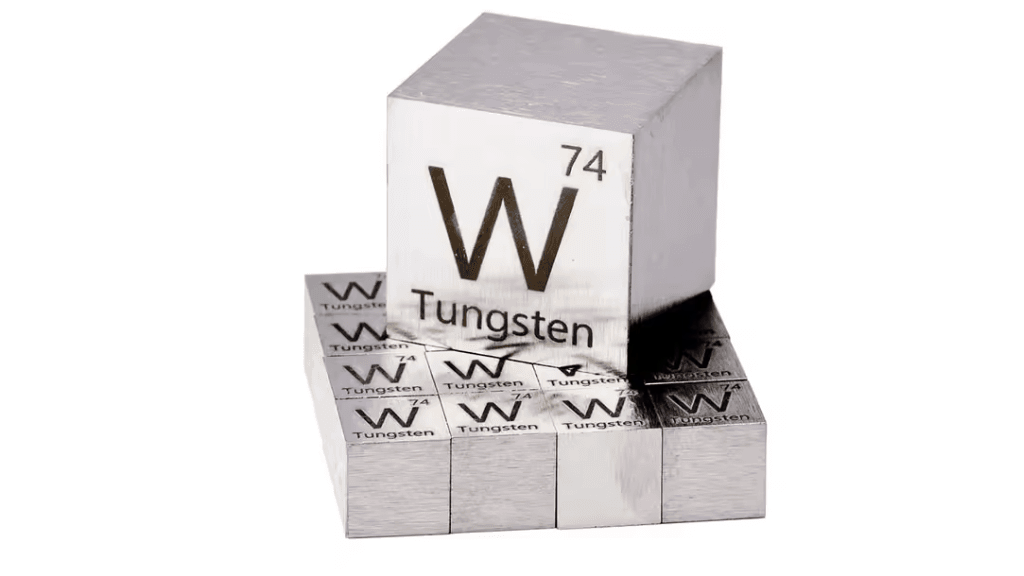

タングステン鋼

タングステン鋼、またはタングステンカーバイドは、極めて高い硬度と耐摩耗性で知られています。切削工具、採鉱設備、および高い耐久性が求められる用途に使用されます。

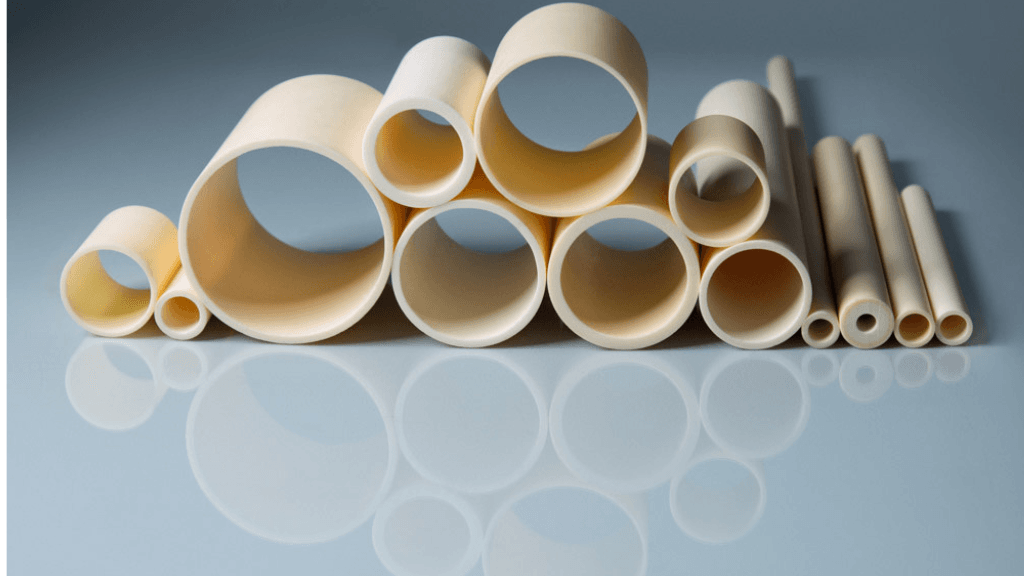

アルミナセラミックス

アルミナセラミックは、高い硬度、熱安定性、耐摩耗性、耐腐食性が高く評価されており、電気絶縁体、切削工具、生体医療機器などの用途に使用されています。

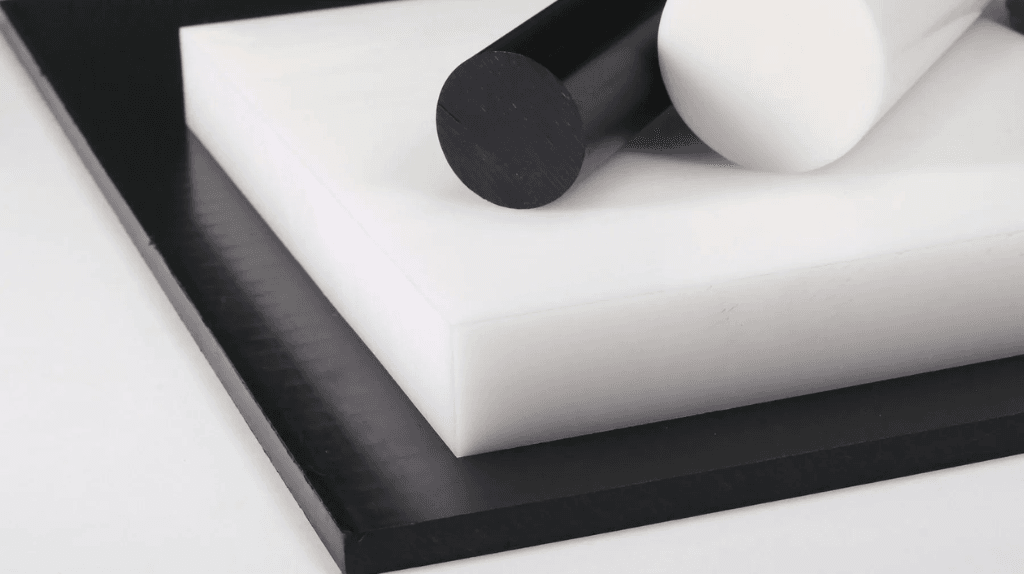

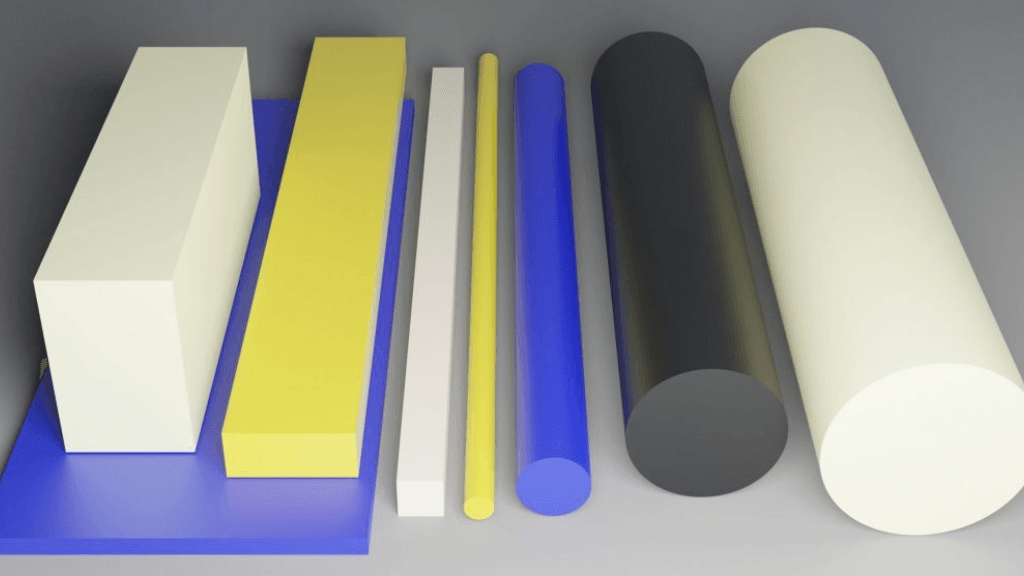

プラスチック

ポム

POM(ポリオキシメチレン)は、優れた寸法安定性と耐摩耗性で知られる高剛性、低摩擦のエンジニアリングプラスチックであり、ギアやベアリングなどの精密部品に最適です。

MCナイロン

MCナイロン(モノマーキャストナイロン)は、高い機械的強度、靭性、耐摩耗性を備えており、ギア、ベアリング、ローラーなどの産業用途に広く使用されています。

ポリ塩化ビニル

PVC (ポリ塩化ビニル) は、耐薬品性と耐久性に優れた多用途でコスト効率に優れたプラスチックで、パイプ、継手、窓枠などの建設によく使用されます。

ピーク

PEEK (ポリエーテルエーテルケトン) は、優れた耐薬品性、機械的特性、熱安定性を備えた高性能熱可塑性プラスチックで、航空宇宙、医療、工業用途に適しています。

PA6

PA6 (ポリアミド 6 またはナイロン 6) は、優れた耐摩耗性と靭性を備えた強力で耐久性のあるプラスチックで、自動車部品、工業部品、繊維製品によく使用されます。

超高分子量

UHMW (超高分子量ポリエチレン) は、優れた衝撃強度、低摩擦、優れた耐摩耗性で知られており、摩耗ストリップ、ガイド レール、ライナーに最適です。

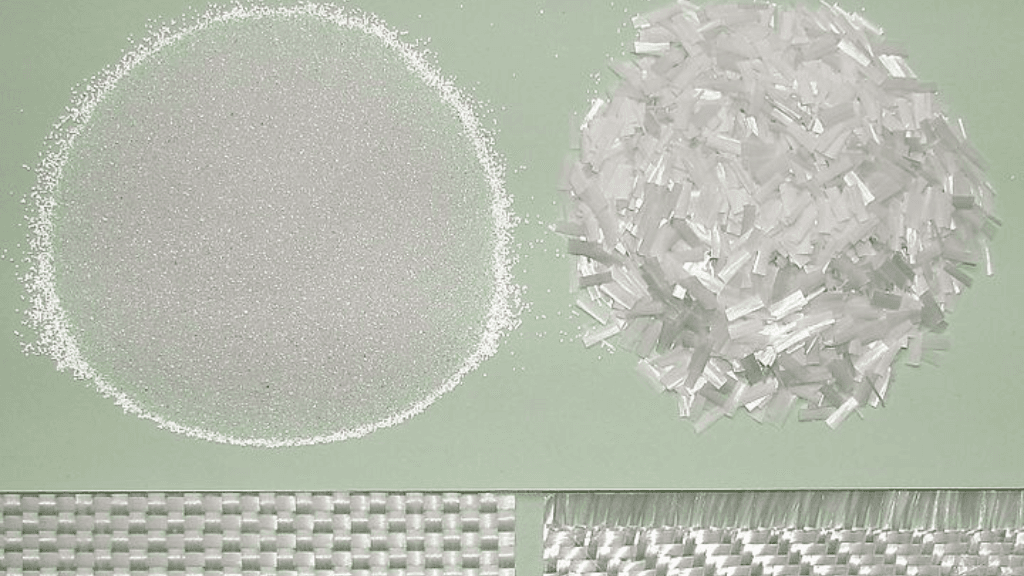

ガラス繊維

ガラス繊維強化プラスチックは、高い強度対重量比、優れた熱絶縁性および電気絶縁性を備えており、建設、自動車、航空宇宙産業で広く使用されています。

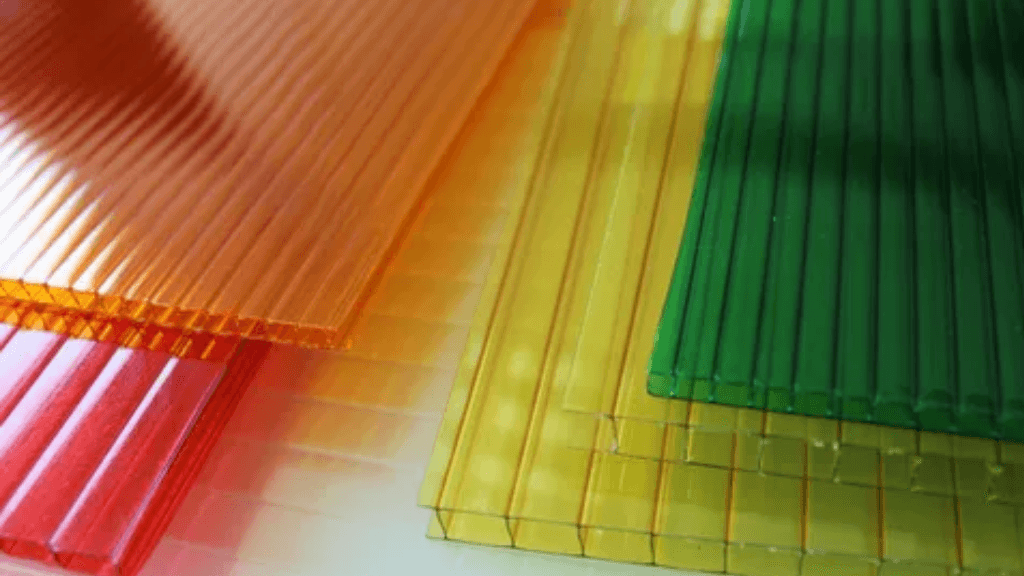

ポリカーボネート

ポリカーボネートは、耐衝撃性と光学的透明性に優れた丈夫な透明プラスチックで、眼鏡レンズ、医療機器、保護具などの用途に使用されます。

テフロン

テフロン (PTFE) は、優れた耐薬品性、低摩擦性、高温安定性で知られており、ノンスティックコーティング、シール、ガスケットに最適です。

ゴム

ゴム素材は、優れた弾力性、耐摩耗性、衝撃強度を備えており、シール、ガスケット、タイヤ、フレキシブルホースなどの製品に使用されます。

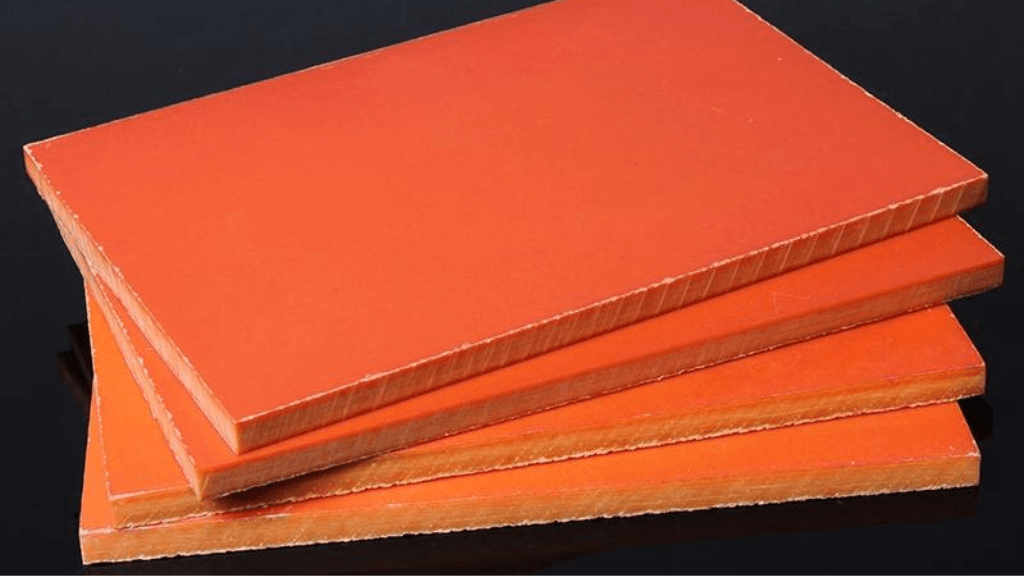

ベークライト

ベークライトは、優れた電気絶縁性と耐熱性を備えた熱硬化性フェノールホルムアルデヒド樹脂で、電気絶縁体、ラジオや電話の筐体、台所用品などに使用されます。

CNC加工表面仕上げ

名前

材料

色

テクスチャ

リンク

サンドブラスト

サンドブラストは、表面を洗浄し、錆、塗料、その他の汚染物質を除去し、金属をさらに処理またはコーティングするための準備をします。工業、自動車、建設の分野で広く使用されています。

金属

ブラッシング

ブラッシングにより、金属表面の質感と外観を向上させる一方向のサテン仕上げが実現します。さまざまな製品に洗練されたモダンな外観を与えるためによく使用されます。

アルミニウム

陽極酸化処理

陽極酸化処理により耐食性が向上し、耐摩耗性や硬度が高まり、金属表面が保護されます。機械部品、航空機、自動車部品、精密機器などに広く使用されています。

アルミニウム

絵画

塗装は美観を高め、環境要因に対する保護層を追加します。自動車、工業、消費者向け製品によく使用されます。

金属 / プラスチック

不動態化

活性化は、表面から遊離鉄を除去し、ステンレス鋼やその他の金属に保護酸化物層を形成することで耐食性を向上させます。航空宇宙、医療、食品加工業界で広く使用されています。

金属

クロムメッキ

クロムメッキは、光沢のある鏡のような仕上がりと優れた耐腐食性を提供し、金属部品の耐久性と美観を向上させます。自動車、家庭用備品、工業用途でよく使用されます。

金属

亜鉛メッキ

亜鉛メッキは優れた耐腐食性を備え、金属部品の寿命を延ばし、きれいで滑らかな仕上がりを実現します。自動車、電気、工業用途で広く使用されています。

金属

ニッケルメッキ

ニッケルメッキは、優れた耐腐食性、硬度、光沢のある仕上がりを提供し、金属部品の外観と耐久性の両方を向上させます。自動車、電子機器、装飾用途で広く使用されています。

金属

シルバー/ゴールドメッキ

銀メッキと金メッキは、優れた導電性、耐腐食性、豪華な仕上がりを提供し、金属部品の機能性と美観の両方を向上させます。これらのメッキは、電子機器、宝飾品、装飾用途で広く使用されています。

金属

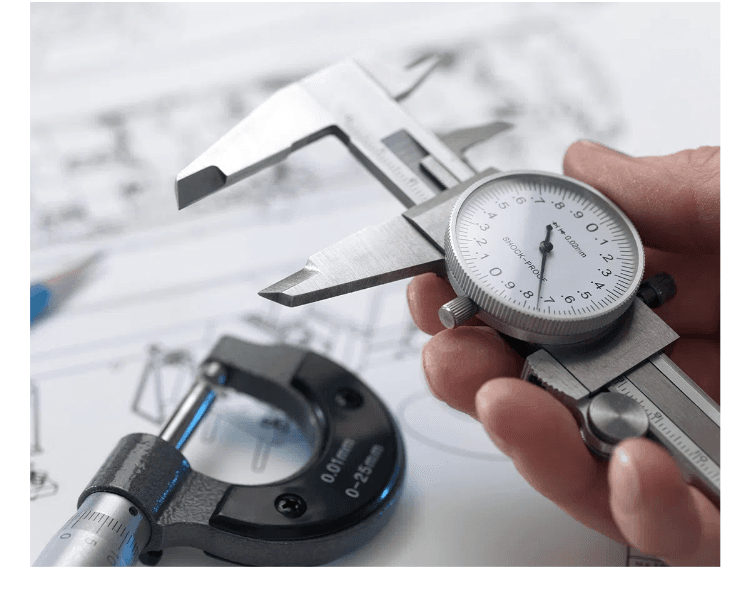

精度と正確さの制御

品質は私たちの最優先事項です

Witcool Precision & Accuracy Control は、あらゆる掘削ニーズに対応する最高品質のソリューションを提供します。当社の高度なテクノロジーは、最も厳しい条件でも精密で正確なパフォーマンスを保証します。高品質の鋼と革新的なデザインで作られた Witcool ツールは、手作業とそれに伴うコストを一貫して削減します。電力使用量を最適化し、材料の無駄を最小限に抑えることで、長期的な節約と効率化につながります。鉱業、建設業、または精密掘削を必要とするあらゆる業界のいずれであっても、Witcool Precision & Accuracy Control は信頼性が高く、耐久性があり、コスト効率の高いツールを提供します。生産性を高め、常に優れた結果を出すために、Witcool をご利用ください。

CNC加工における許容誤差

Witcool は、高度な CNC マシンを使用して、部品の加工において高い精度を確保しています。最大 ±0.005 mm の許容範囲を実現し、偏差が最小限で優れた精度の部品を製造できます。

| アイコン | 標準 | 許容範囲 | アイコン | 標準 | 許容範囲 | |

|---|---|---|---|---|---|---|

| 共通の許容範囲 | 0.0004" (±10μm / ±0.01mm) | 直径公差 | 0.00004" (±1μm / ±0.001мм) | |||

| 平坦性 | 0.00004インチ(2μm / 0.002mm) | 真っ直ぐさ | 0.00004" (1μm / 0.001mm) | |||

| 垂直性 | 0.0002" (5μm / 0.005mm) | 並列処理 | 0.0001" (2.5μм / 0.0025мм) | |||

| 丸み | 0.0002" (5μm / 0.005mm) | 同心 | 0.00002" (0.5μм / 0.0005мм) | |||

| 円筒度 | 0.0002" (5μm / 0.005mm) | 対称 | 0.0003" (8μm / 0.008mm) | |||

|

|

円形ランアウト | 0.00004" (1μm / 0.001mm) | 位置許容度 | 0.005ミリメートル |