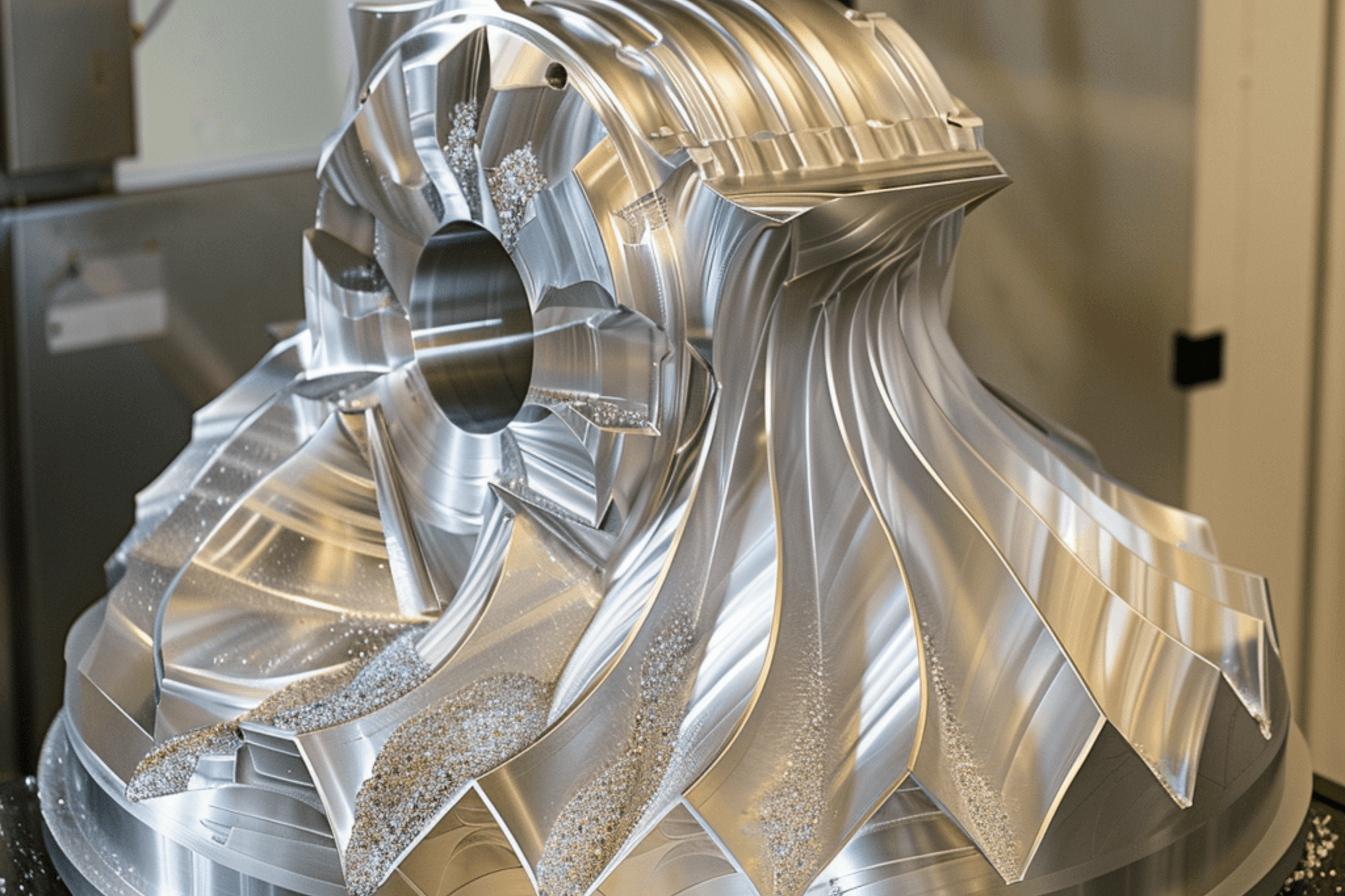

Witcool の 5 軸 CNC 加工は、厳しい公差、迅速なセットアップ、高精度を備えた複雑で精密な部品を生産します。航空宇宙、自動車、医療業界に最適です。

当社の専門チームは、お客様のあらゆるプロジェクト ニーズを満たすために、卓越した専門知識と献身的な姿勢を提供します。

試作から仕上げまでワンストップサービスで調達プロセスを合理化します。

当社は、精度、耐久性、卓越した職人技を備えた高品質の 5 軸加工サービスを提供しています。

Witcool の迅速な配送により、ご注文は毎回迅速かつ効率的に届きます。

当社は、精度、品質、信頼性の高い納品が保証された低コストの 5 軸 CNC 加工サービスを提供しています。

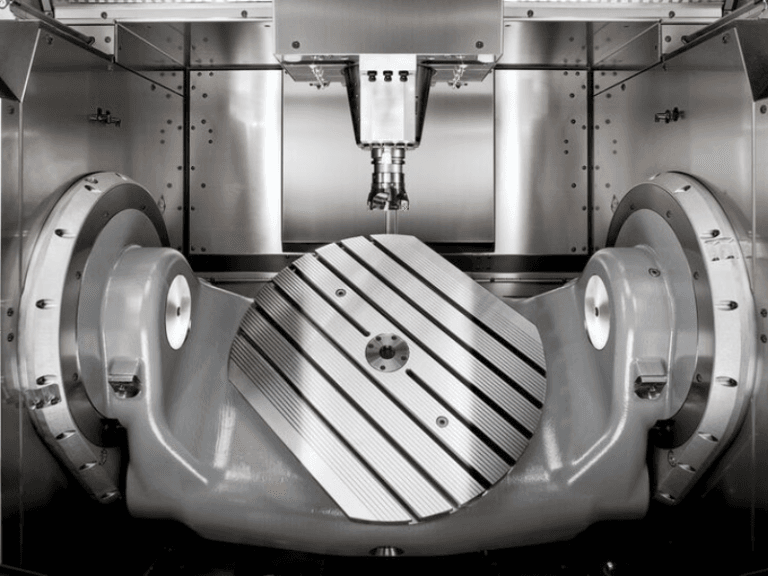

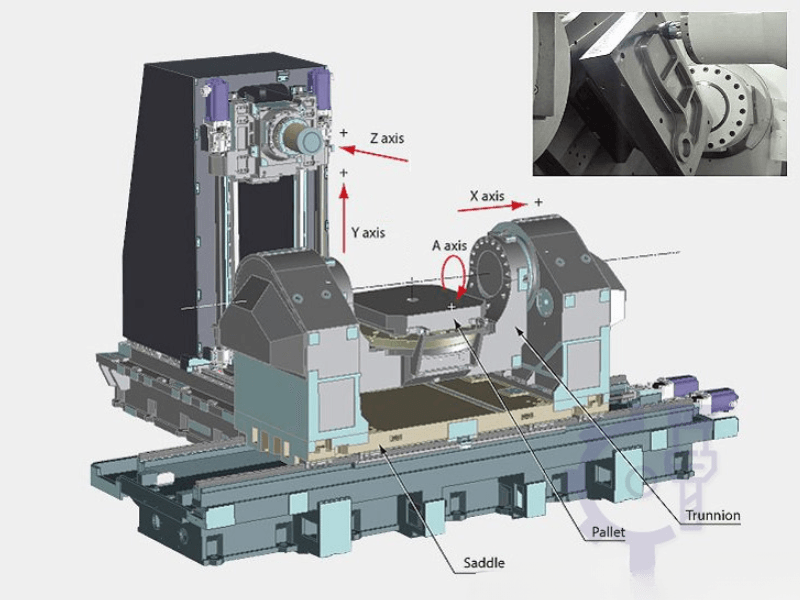

精密工学の最高峰である 5 軸加工により、これまでにない精度で複雑な形状を作成できます。当社の 5 軸加工機は、従来の 3 軸加工とは異なり、切削工具または部品を 5 つの別々の軸に沿って同時に移動できるため、複雑なコンポーネントを効率的に製造できます。

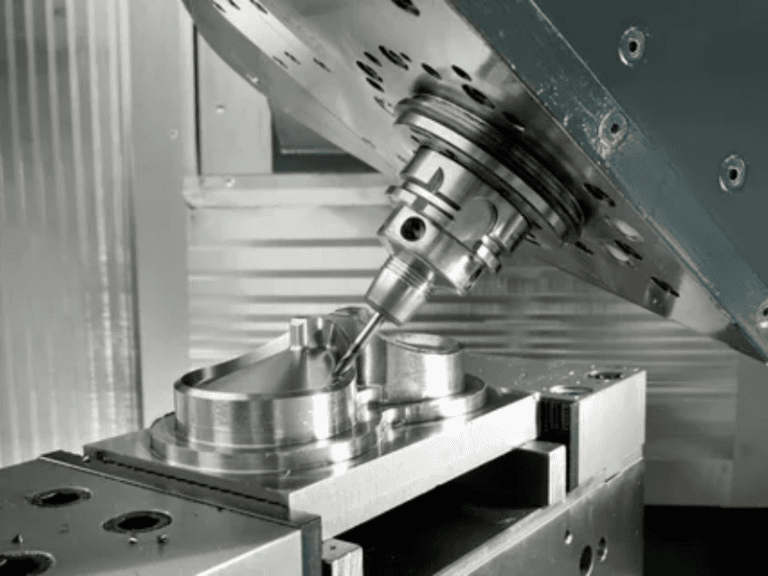

5 軸 CNC 加工は、5 方向に移動できる切削工具を使用して材料を成形する技術です。どこからでもワークピースにアプローチし、工具は X、Y、Z の直線軸に沿って移動し、A 軸と B 軸で回転します。工具が X、Y、Z 軸に沿ってのみ移動する 3 軸加工に比べて、この適応性は大きな利点をもたらします。

5 軸加工では、精度、効率、速度が大幅に向上します。複雑なカットを 1 つの構成で実行できるため、複数のセットアップが不要になり、加工時間が短縮されます。これにより、許容誤差が小さく、仕上げが滑らかな、高品質のコンポーネントが実現します。5 軸マシンは、より複雑な形状や形状を処理できるため、航空宇宙、自動車、医療機器などの分野にも適しています。

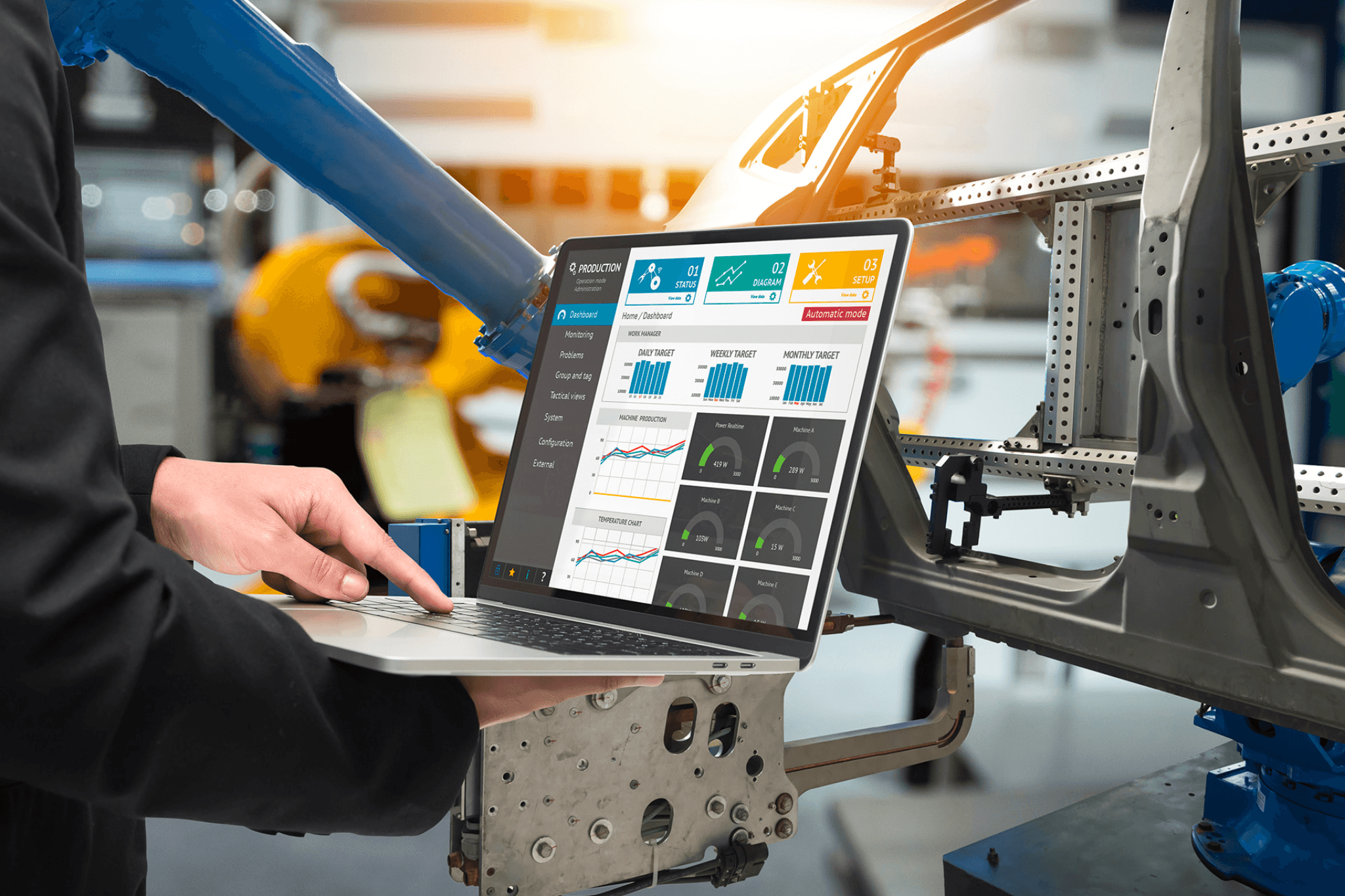

5 軸 CNC 加工は、生産される製品の精度、効率、速度を向上させる適応性の高い技術です。複雑なカットを 1 つの構成で実行できるため、複数のセットアップが不要になり、加工時間が短縮されます。精密な動作が必要な部品や、GD&T 基準とフィーチャーが最小限のセットアップで向上する部品は、5 軸マシンに最適です。

5 軸加工は、生産能力の向上を目指すクライアントにとって、より優れた解決策となります。今日の競争の激しい製造現場では、複雑な部品を高い精度と短いリードタイムで作成できる 5 軸加工の能力は計り知れません。

当社の 5 軸 CNC 加工は、厳格な業界標準を満たす、精密で複雑なコンポーネントを迅速かつ効率的に提供します。

同時 5 軸 CNC 加工により、比類のない精度と効率を実現し、最小限のセットアップと短縮されたリード タイムで複雑な部品を製造できます。

当社の 3+2 軸 CNC 加工は柔軟性と精度を兼ね備えており、セットアップを減らして複雑な部品を効率的に生産できます。

当社の 5 軸 CNC 加工は厳しい公差を保証し、複雑な部品に優れた精度を提供し、厳しい業界の仕様と基準を満たします。

当社の高度な 5 軸 CNC 加工により、リードタイムが短縮され、優れた精度と効率で複雑な部品を迅速に生産できます。

5 軸 CNC 加工における当社の迅速な対応能力を活用して、複雑なコンポーネントの迅速な処理と高品質の生産を保証します。

革新的な問題解決のために 5 軸 CNC 加工を活用することで、複雑なエンジニアリングの課題に対して、優れた効率で正確かつ多用途なソリューションを実現できます。

同時多軸動作により比類のない精度と効率を実現し、航空宇宙、自動車、医療などの要求の厳しい業界向けに複雑な形状、セットアップの削減、優れた品質を実現します。

5 軸 CNC 加工により、製造において比類のない精度と品質が保証され、さまざまな複雑な用途に対して一貫して厳しい許容差を備えた精巧で高品質の部品が提供されます。この高度な技術により、非常に詳細で正確なコンポーネントの作成が可能になり、エラーが最小限に抑えられ、優れた品質が保証されます。

5 軸 CNC 加工により、従来の 3 軸加工では困難または不可能な複雑な形状の製造が可能になります。この柔軟性により、複雑なデザインを効率的に製造でき、複数のセットアップの必要性が減り、より高い精度が保証されます。

5 軸 CNC 加工により、部品の複数の面を 1 回のセットアップで加工できるため、リード タイムが大幅に短縮され、生産効率が向上します。この機能により、操作間のダウンタイムが最小限に抑えられ、スループットが向上し、複雑なプロジェクトのターンアラウンド タイムが短縮されます。

5 軸 CNC 加工では、必要なセットアップと操作の数を減らすことで、人件費と材料の無駄を削減できます。この効率性により、少量生産と大量生産の両方でコストが削減され、複雑で高精度な部品を製造するためのコスト効率の高いソリューションになります。

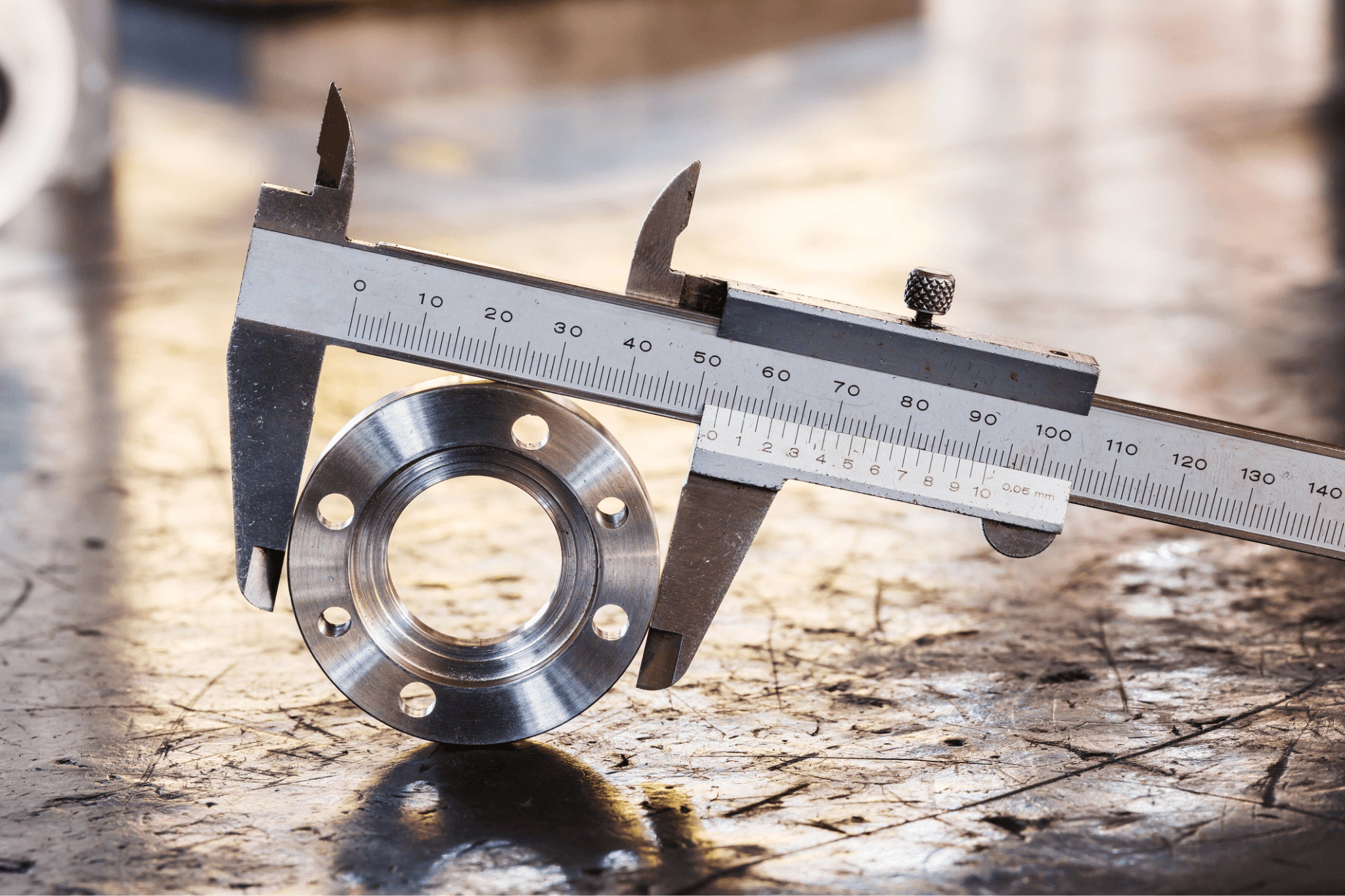

多くの場合 ±0.0004 mm 以内という極めて厳しい公差を実現できるため、航空宇宙、医療、高精度産業における複雑な部品の優れた精度、一貫性、品質を保証します。

共通の許容範囲

0.0004” (±10μm / ±0.01mm)

標準許容範囲

金属: ISO2768-f プラスチック: ISO 2768-m

線形寸法

Φ0.5mm

穴寸法(未記入)

±0.025mm

シャフト径

±0.025mm

エッジ条件

鋭い角は面取りまたは半径の形で除去されます。面取りのサイズ、または結果として得られる半径は、図面に示さなければなりません。

ねじとタップ穴

直径: Φ5mm以上 深さ: 4-6×直径

テキスト/彫刻内容

鋭い角は面取りまたは半径の形で除去されます。面取りのサイズ、または結果として得られる半径は、図面に示さなければなりません。

リードタイム

10営業日<100個

パートスタディ

材料: アルミニウム6082T

表面処理: ビーズブラスト+アルマイトブラック

数量: 10個

応用: 高精度、耐久性、軽量性が重要となる、特にドローンのアクセサリなどの航空・宇宙部品の製造に使用されます。

Witcoolでは、3Dプリントプロセスのあらゆる段階を厳格に管理し、高い製品品質と精度を確保しています。標準規格を遵守し、革新的な技術を導入することで、あらゆるプロジェクトの品質向上に貢献する信頼性の高いソリューションを提供しています。

デジタルモデルは層にスライスされ、プリンターは材料を順番に堆積(溶融または硬化)して、下から上に向かってオブジェクトを構築します。

一般的なプロセスには以下が含まれます FDM(FFF), サービスレベル保証, セルス, DLP, MJF、 そして DMLS/EBMそれぞれ異なる材質と精度レベルに適しています。

プリンターは一般的に 人民解放軍, アブソリュート, PETG, TPU, ナイロン, ポリカーボネート, 樹脂、さらには 金属、セラミック、またはバイオマテリアル。

その STL 1987 年に開発されたこのフォーマットは、三角形を使用してオブジェクトの表面形状をエンコードし、スライスと印刷で最も広く受け入れられているフォーマットとなっています。

利点: カスタムジオメトリ、材料無駄の削減、ラピッドプロトタイピング、製造の柔軟性。

デメリット: 大きな部品の場合は遅くなり、サイズに制約があり、スケーラビリティが制限され、一部のプロセスではコストが高くなります。

使用されているのは 航空宇宙, 自動車, 薬, 教育, 建築, 消費財、 そして 防衛特にプロトタイプやカスタムパーツに最適です。

簡単な見積もりをご希望の場合は、Witcool チームにお問い合わせください。

STEP、IGS、または DWG 形式の 3D CAD ファイル、PDF 形式の 2D ファイル。

PDF 図面には、許容差、重要な寸法、およびネジ穴が含まれている必要があります。

簡単な見積もりをご希望の場合は、Witcool チームにお問い合わせください。

STEP、IGS、または DWG 形式の 3D CAD ファイル、PDF 形式の 2D ファイル。

PDF 図面には、許容差、重要な寸法、およびネジ穴が含まれている必要があります。