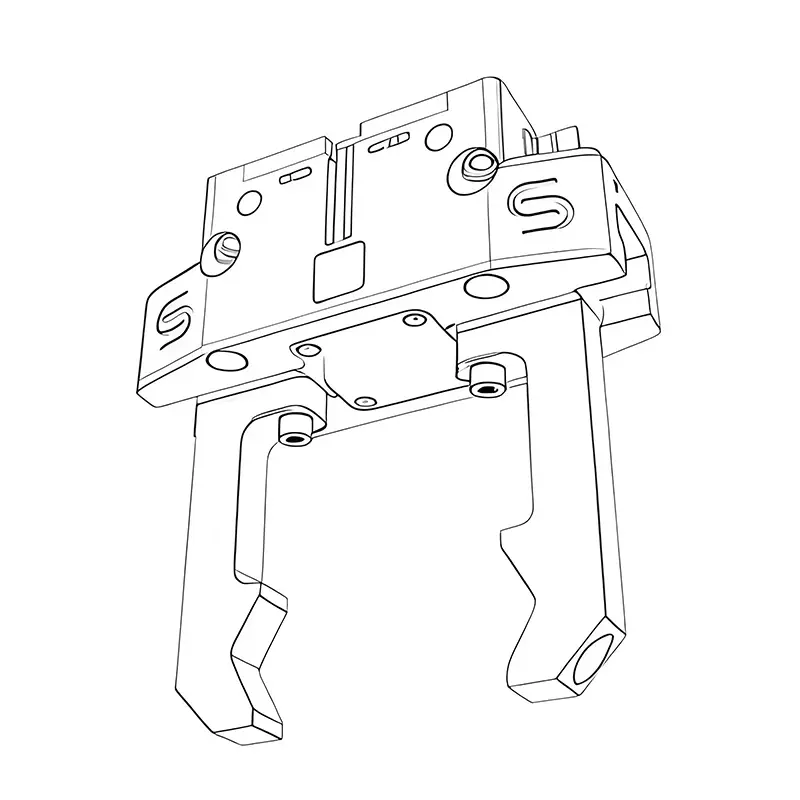

CNC Machining for Robotics & Automation Components

CNC machining guarantees precise dimensions and tolerances, boosting robot performance and reliability. The integration of robotics and CNC machining makes production more flexible and intelligent.

- Ensures minimal tolerances and high precision.

- Reduces waste and accelerates production.

- Suitable for working with metals such as aluminum and steel.

- Guarantees repeatability in mass production.

Trusted by

Why CNC Machining is Important for Robotics

CNC machining provides precise parts for robots, enhancing their stability and reliability. CNC machines create complex components, process various materials, ensuring durability and consistency.

- High Precision:

Key components, such as joints and gears, require micron-level precision, which is provided by CNC machining. - Complex Designs:

CNC machines process intricate shapes, ensuring the functionality of robots. - Material Selection:

CNC can process materials ranging from aluminum to titanium, ensuring durability under high load conditions. - Reliability:

Parts machined with CNC have high accuracy, ensuring stable system performance.

Services and Solutions

Witcool CNC Machining offers high-precision CNC machining services, providing customized solutions that drive innovation and deliver exceptional performance in part manufacturing.

CNC Machining

Creating precise and complex structures through milling, turning, and post-processing, perfectly suited for both intricate prototypes and functional metal parts.

Die Casting

Rapid production of cast parts and intermediate tooling, optimized for mass production with consistent quality.

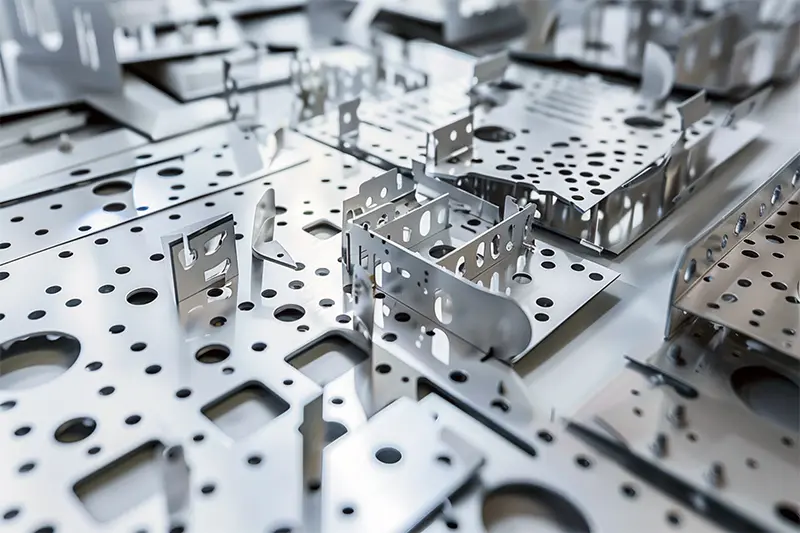

Sheet Metal Processing

Provides flexibility in forming precise metal components for various applications, ensuring both adaptability and accuracy.

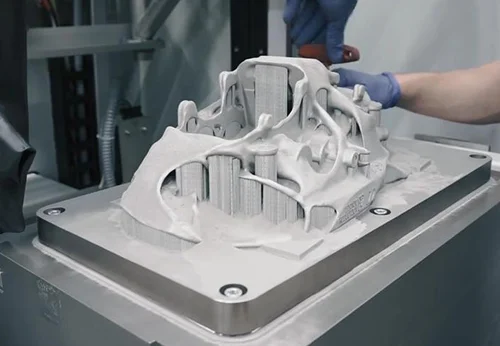

3D Printing

A fast and versatile process that enables quick creation of complex shapes from a variety of materials, ideal for innovative designs.

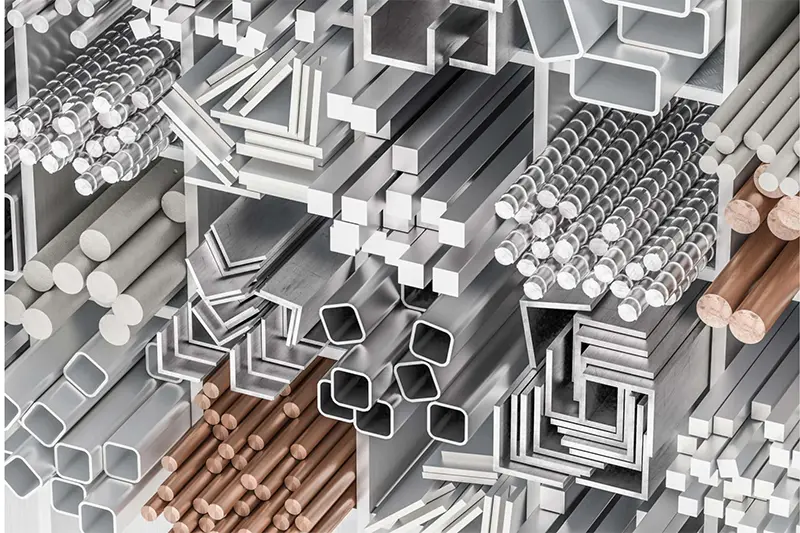

Materials and Surface Finishing

Materials

We offer a wide range of materials, including metals, plastics, and composites.

Surface Finishing

Our high-quality finishing enhances the durability and appearance of parts, meeting the requirements for both smooth and textured surfaces.

Robotics Manufacturing Capabilities

Drawing on extensive expertise in the robotics industry, Witcool has partnered with ABB and Universal Robots to deliver top-tier CNC machining solutions. Our dedication to precision and innovation enables us to manufacture intricate robotic components that adhere to rigorous quality benchmarks. By embracing cutting-edge technologies, we consistently align with the evolving requirements of our partners.

"We are highly impressed with the precision and quality delivered by the CNC machining team. The structural components they provided for our industrial robots exceeded our expectations in terms of accuracy, durability, and lightweight design. Their ability to meet tight tolerances and deliver prototypes within our accelerated timeline has been crucial to our product development process. We look forward to continued collaboration on future projects!" ---- ABB Robotics

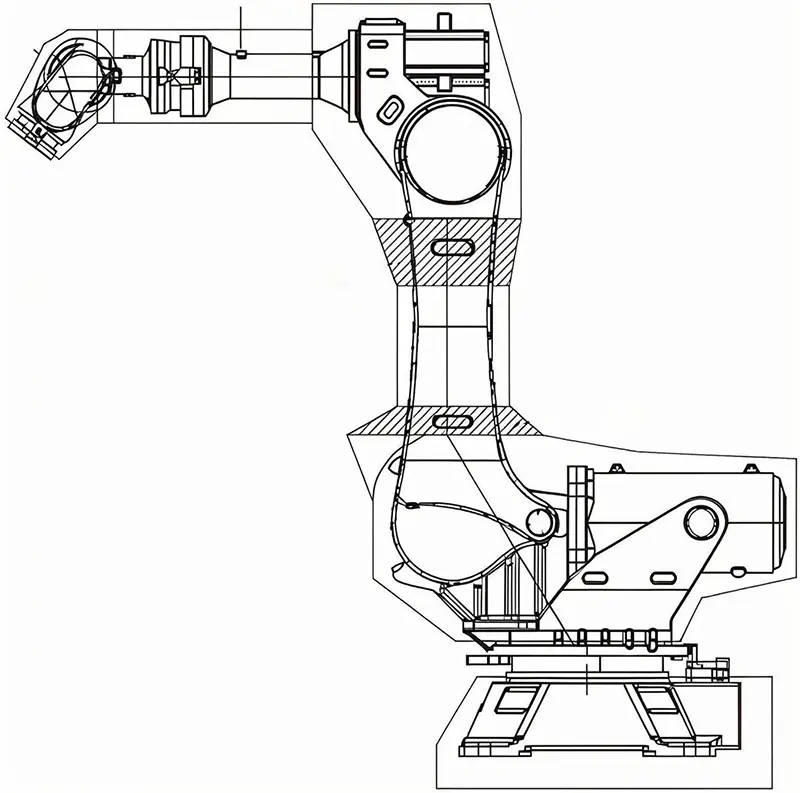

Precision CNC Machining for Industrial Robot Frames

ABB Robotics required high-precision structural components for their industrial robots, including base frames and joint housings. These parts demanded tight tolerances to ensure smooth operation and structural stability. The components were designed for heavy-duty applications in industries such as automotive manufacturing and logistics automation.

● 5-Axis CNC Machining: To achieve complex geometries and high precision.

● Aluminum Alloy Processing: Lightweight and durable material for enhanced robot efficiency.

● Surface Treatment: Anodizing to improve corrosion resistance and extend lifespan.

1. Achieved dimensional accuracy within ±0.005 mm, meeting ABB's strict requirements.

2. Reduced component weight by 15%, enhancing the robot's energy efficiency.

3. Delivered prototypes within two weeks, accelerating ABB's development timeline.

"The custom assembly jigs and fixtures provided by the CNC machining team have significantly enhanced our production efficiency. Their attention to detail and ability to achieve tight tolerances have ensured consistent quality in our collaborative robot assembly process. We also appreciate their dedication to meeting our demanding schedule without compromising on quality. They are a trusted partner, and we highly recommend their services." ---- Universal Robots

Precision CNC for Collaborative Robot Assembly Fixtures

Universal Robots required customized assembly jigs and fixtures to streamline the production of their collaborative robots (Cobots). These tools needed to ensure precise alignment during assembly and testing, minimizing human error and improving production efficiency.

● 3-Axis CNC Machining: Ideal for producing high-precision flat and angular surfaces.

● High-Strength Steel Processing: To withstand repeated use in manufacturing environments.

● Custom Design: Tailored to Universal Robots' unique assembly workflows.

1. Enhanced assembly accuracy by 20%, significantly reducing rework rates.

2. Manufactured fixtures with a tolerance of ±0.01 mm, ensuring consistent quality.

3. Delivered tools within four weeks, meeting Universal Robots' tight production schedule.

Benefits of Integrating Robotics with CNC Machining

Witcool CNC Machining provides high-precision CNC machining services, offering customized solutions that foster innovation and deliver outstanding performance in part manufacturing.

Increased Productivity

Robots can operate continuously, without breaks or fatigue, leading to increased production volume and reduced lead times. This makes manufacturing more efficient and timely.

Improved Precision

Robots can achieve high accuracy, which is especially important when producing complex components for medical devices and other applications. High precision ensures consistent product quality and reduces variations.

Cost Reduction

In the long run, using robots reduces labor costs and minimizes errors, leading to significant economic benefits by lowering labor expenses and defect corrections.

Flexibility and Scalability

Robotic systems can be easily reconfigured to perform various tasks, allowing manufacturers to adapt to changing production needs. This ensures flexibility in production management and enables scaling up production to meet growing demands.

Quality Assurance

Witcool delivers ≤5μm CNC precision (ISO 9001:2015 certified) with 99.8% QA pass rate. 5-stage inspection process ensures robotic components meet MIL-STD-1916 standards. 200+ industrial robot manufacturers served, 0.002% defect rate since 2012. Medical-grade titanium machining capabilities (ISO 13485 compliant).

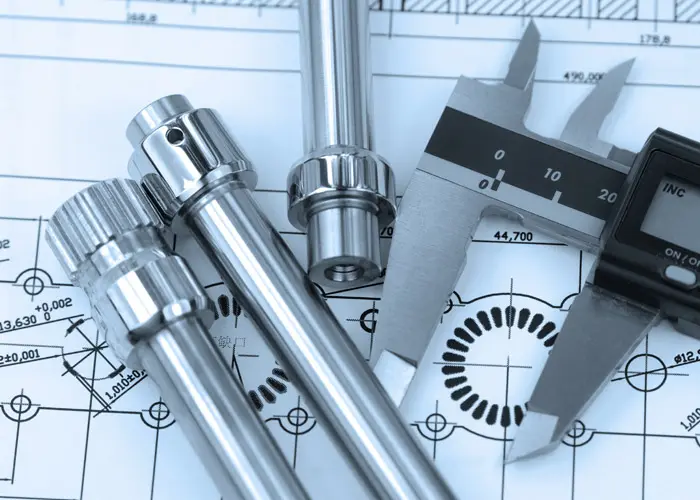

Precision Machining and Quality Control

In the robotics industry, CNC machining is crucial for producing key components such as actuators, gears, and robotic arms. Witcool enforces strict quality control measures at every stage of production, ensuring that each part meets the most demanding tolerance specifications. We have implemented a Total Quality Management (TQM) system, where every production step is monitored in real-time to minimize defects and errors. To guarantee precision throughout the process, we utilize advanced Coordinate Measuring Machines (CMM) and optical measurement systems.

quality control processes:

Raw Material Inspection:

Before production begins, all materials undergo stringent inspections to ensure compliance with design standards and industry norms.

In-Process Inspection:

At each critical stage of production, control checkpoints are implemented to prevent the accumulation of errors and ensure specification compliance.

Final Inspection and Verification:

Upon completion of production, thorough inspections of dimensions, surface quality, and tolerances are conducted to guarantee full compliance with technical requirements.

- These processes ensure maximum quality at every stage, guaranteeing the reliability of the final product.

Certification and Industry Standards

Our manufacturing operations are ISO 9001 certified, confirming that all robotics components meet international quality standards. Additionally, our materials and processes adhere to industry regulations such as RoHS and REACH, ensuring compliance with environmental and safety standards.

Materials and Processing Standards

Robotics components demand materials with high strength, precision, and durability. Witcool selects materials that meet industry specifications, including aluminum alloys, stainless steel, and titanium, applying optimized machining parameters to guarantee full compliance with strict requirements.

Product Testing and Verification

Witcool conducts thorough testing and verification at every production stage, including fatigue, corrosion resistance, and impact strength tests, which are essential for robotics components. These tests validate the superior performance and reliability of our parts under extreme conditions.

Specific Testing and Verification Processes:

Fatigue Testing:

Simulates load stress on components during prolonged use to prevent failure under tension.

Corrosion Resistance Testing:

Evaluates material resistance to corrosion for parts exposed to high humidity or aggressive environments.

Impact Testing:

Assesses the strength and durability of components under sudden impacts or high pressure.

Dimensional Verification:

Measures part accuracy using high-precision measurement systems to ensure compliance with micron-level tolerances.

Comprehensive Tracking System

Witcool employs a digital tracking system that records every stage, from raw materials to finished products, ensuring production processes can be traced at any time. This approach provides transparency in management and helps resolve potential quality issues swiftly.

Customer Feedback and Continuous Improvement

We actively incorporate feedback from clients in the robotics industry to continuously improve our CNC machining capabilities. By refining our processes and adopting cutting-edge machining techniques, Witcool ensures the delivery of robotics components that exceed the highest industry standards.

Frequently asked questions

CNC machining is vital in robotics, enabling precision manufacturing of parts like frames, joints, and tools, while supporting innovation and automation with high-quality solutions.

What is the role of CNC machining in robotics?

CNC machining is essential for manufacturing precise components used in robotic systems, including frames, joints, and custom tools.

What types of robotic components are made using CNC machining?

CNC machining produces robot frames, gear systems, housings, end effectors, and assembly jigs with high precision and quality.

What materials are commonly used for CNC-machined robotic parts?

Materials like aluminum, titanium, stainless steel, and engineering plastics are frequently used due to their strength and light weight.

How does CNC machining ensure accuracy in robotic components?

CNC machining uses advanced software and multi-axis machines to achieve tight tolerances and consistent precision.

Why is CNC machining preferred for prototyping robotic parts?

CNC machining offers fast production, high accuracy, and the flexibility to handle complex designs, making it ideal for prototypes.

Can CNC machining handle custom designs for robotics?

Yes, CNC machining is highly adaptable to unique and intricate designs, meeting specific requirements for robotics applications.