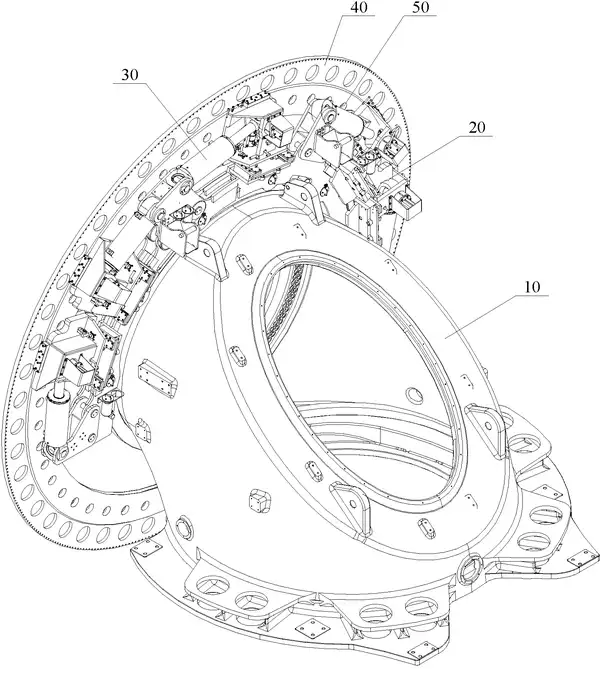

Expert CNC Machining for the Energy Industry

Witcool offers high-precision solutions for the energy sector, utilizing 5-axis CNC machining to manufacture turbine components, generators, and other equipment. We ensure compliance with strict quality and durability standards, guaranteeing reliable equipment performance under increased loads.

- Ensures minimal tolerances and high precision.

- Reduces waste and accelerates production.

- Guarantees repeatability in mass production.

Trusted by

Why Choose Wticool CNC

At Witcool, we leverage cutting-edge CNC machining technologies to provide exceptional precision and reliability. We ensure rigorous quality control at every stage and deliver projects promptly, making us a trusted partner for complex ventures.

Commitment to Sustainability

Witcool is dedicated to sustainable practices at every level. We use eco-friendly materials, integrate energy-efficient processes, and actively strive to reduce carbon emissions. Our sustainability initiatives include waste reduction and energy consumption optimization, aligned with our long-term goals.

Our dedication to quality is backed by stringent testing and certifications such as ISO, ensuring compliance and exceeding industry standards.

Tailored Solutions

We deliver customized solutions to meet specific solar energy project requirements, such as bespoke machining services for unique components or flexible manufacturing capabilities adaptable to various scales and needs. Our focus on client goals ensures precision and on-time delivery.

Competitive Pricing with Value

We offer competitive pricing while prioritizing overall value. Our solutions encompass cost savings, durability, efficiency, and high product performance, helping clients minimize operational costs. Flexible manufacturing optimizes projects for maximum benefits.

Outstanding Customer Support

Our commitment to exceptional customer service includes prompt responses, project planning assistance, and continuous support throughout the project lifecycle. This customer-first approach distinguishes us in a competitive market and ensures confidence in timely, high-quality solutions.

Energy Components Manufacturing

Our knowledge in CNC machining enables us to deliver exceptional quality and performance when producing critical components for the energy sector. We understand the unique challenges and requirements of the energy industry, offering solutions that meet the highest industry standards.

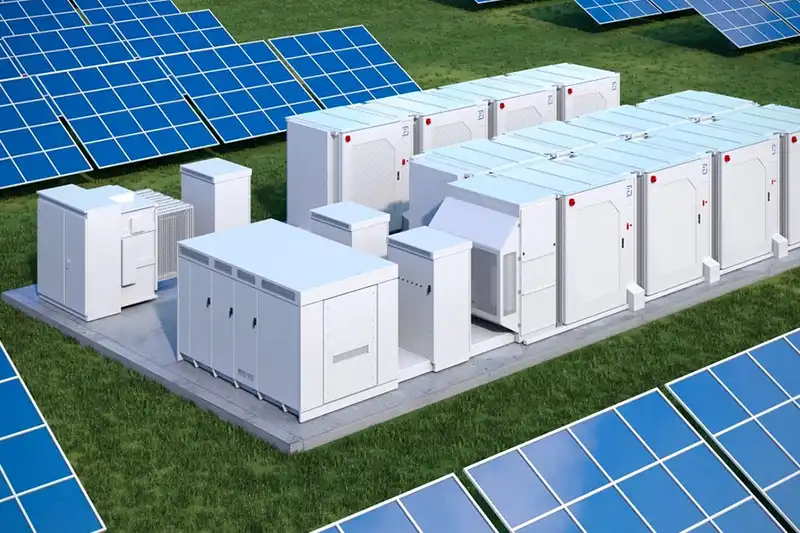

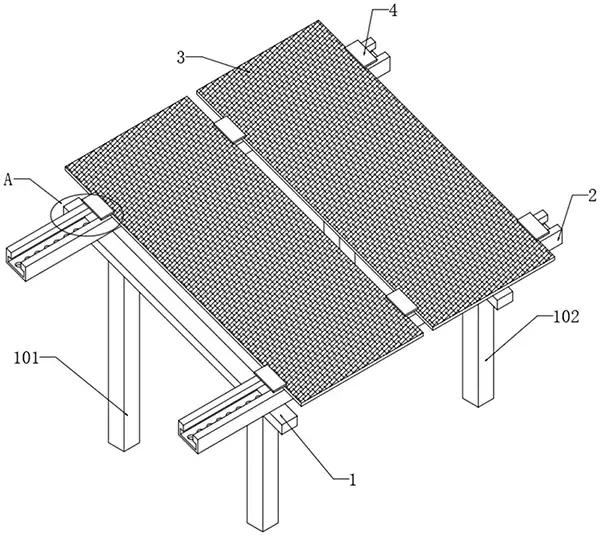

Solar Energy

We have established extensive partnerships with solar energy companies, providing high-precision components for solar panels, trackers, and energy storage systems. Our expertise in materials and processes allows us to manufacture parts that enhance the efficiency and durability of solar technologies.

Energy Storage

As the demand for energy storage solutions grows, we position ourselves as a trusted partner for companies developing advanced battery technologies. Our rapid prototyping and custom manufacturing capabilities enable us to supply components tailored to the evolving requirements of the energy storage market.

Wind Energy

Our experience extends to wind energy, where we deliver high-quality components for wind turbine blades, nacelles, and other essential parts.

Leveraging our extensive expertise in materials, processes, and industry standards, we provide innovative solutions that drive the successful implementation of renewable energy projects.

- Leveraging our extensive expertise in materials, processes, and industry standards, we offer innovative solutions that drive the successful implementation of renewable energy projects.

Services and Solutions

Witcool automotive specialists provide high-precision CNC machining, offering customized solutions that foster innovation and ensure excellent performance in the production of parts.

CNC Machining

Creating precise and complex structures through milling, turning, and post-processing, perfectly suited for both intricate prototypes and functional metal parts.

Die Casting

Rapid production of cast parts and intermediate tooling, optimized for mass production with consistent quality.

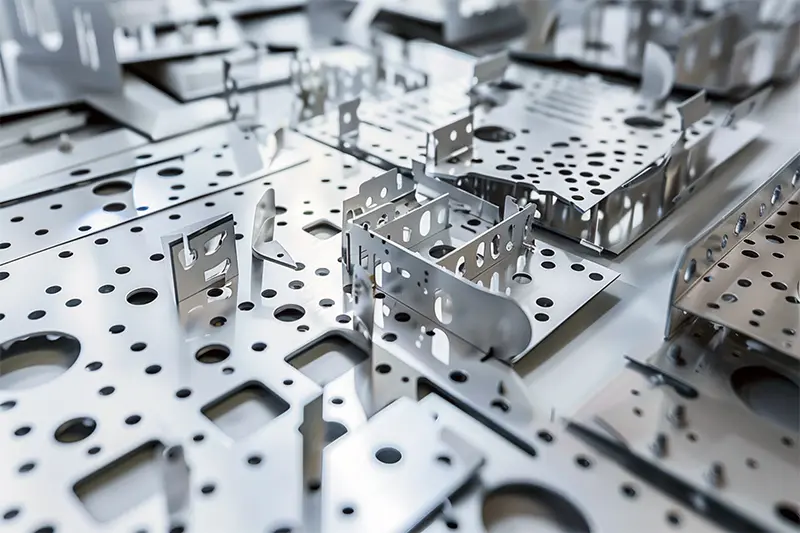

Sheet Metal Processing

Provides flexibility in forming precise metal components for various applications, ensuring both adaptability and accuracy.

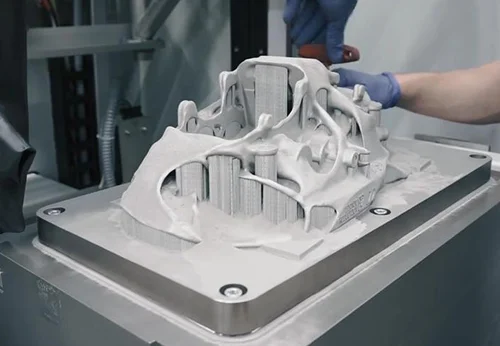

3D Printing

A fast and versatile process that enables quick creation of complex shapes from a variety of materials, ideal for innovative designs.

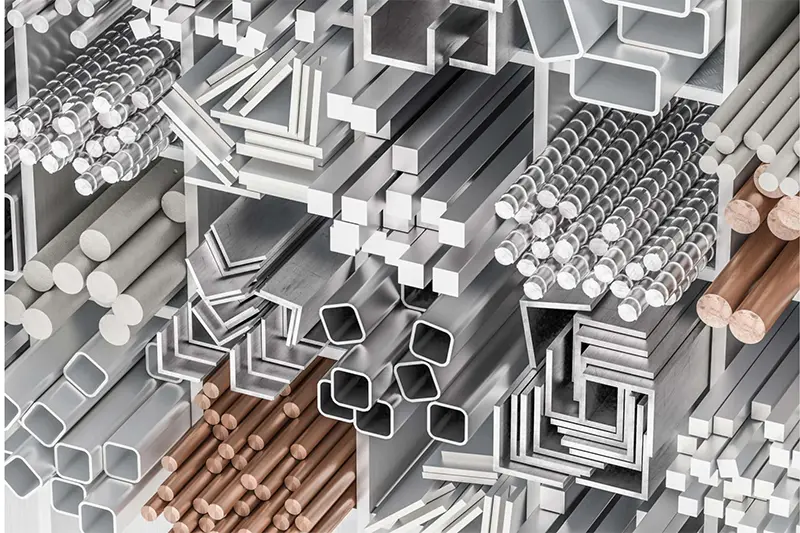

Materials and Surface Finishing

Materials

We offer a wide range of materials, including metals, plastics, and composites.

Surface Finishing

Our high-quality finishing enhances the durability and appearance of parts, meeting the requirements for both smooth and textured surfaces.

Energy Manufacturing Capabilities

Our commitment to providing high-quality CNC machining services enables us to produce critical components that meet the demands of modern energy solutions.

"Witcool exceeded our expectations in precision and speed. Their expertise and responsiveness significantly enhanced the efficiency of solar systems, reduced lead times, and lowered costs. We highly recommend Witcool!"

Enhancing Solar Solutions

Greencells needed to improve solar system performance by delivering precise components and addressing supply chain challenges.

Precision CNC machining, advanced manufacturing technologies, material optimization.

● Reduced lead times by 30%

● Lowered component costs by 15%

● Increased system reliability

"Witcool demonstrated the highest level of precision and innovation, leading to significant improvements in our turbines."

Wind Turbine Component Manufacturing

Witcool partnered with GE Renewable Energy to produce precision components for wind turbines. The goal was to enhance turbine efficiency while minimizing production costs.

5-axis CNC machining, precision grinding, and prototyping.

● Reduced production costs by 20%

● Improved component performance by 15%

Quality Assurance

Witcool guarantees the highest precision and adherence to all quality standards at every stage of production. We follow international norms, including ISO and IATF, in the creation of reliable components for the new energy industry. Rigorous quality control and testing ensure that the products meet the stringent requirements of the new energy sector and demonstrate long-term operational reliability.

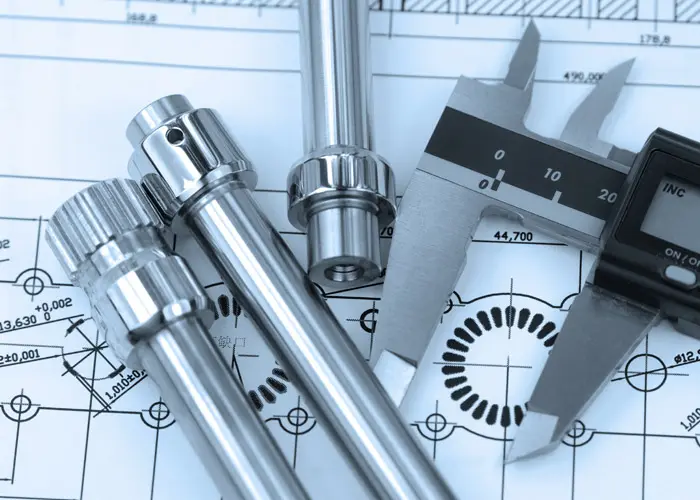

Precision Machining and Quality Control

In the new energy industry, CNC machining is used to produce key components such as battery housings, power management modules, and structural parts. Witcool implements strict quality control throughout all stages, ensuring that each part complies with the most stringent tolerance requirements. We have implemented a comprehensive quality management system (TQM), where every stage of production is monitored in real-time, minimizing defects and errors. We use coordinate measuring machines (CMM) and optical measurement systems to ensure accuracy at every stage of production.

quality control processes:

Raw Material Inspection:

Before production begins, all materials undergo stringent inspections to ensure compliance with design standards and industry norms.

In-Process Inspection:

At each critical stage of production, control checkpoints are implemented to prevent the accumulation of errors and ensure specification compliance.

Final Inspection and Verification:

Upon completion of production, thorough inspections of dimensions, surface quality, and tolerances are conducted to guarantee full compliance with technical requirements.

- These processes ensure maximum quality at every stage, guaranteeing the reliability of the final product.

Certification and Industry Standards

Our manufacturing processes are certified to ISO 9001 and IATF 16949 (new energy industry), confirming that all components meet international quality standards. Materials and processes strictly comply with industry requirements such as RoHS and REACH, ensuring environmental and safety standards are met.

Materials and Processing Standards

Components in the new energy industry require high strength and material precision. Witcool selects materials that meet industry standards, such as aluminum alloys, stainless steel, and titanium, and applies optimized processing parameters to fully meet the requirements.

Product Testing and Verification

Witcool conducts thorough testing and verification at each stage of production, including fatigue testing, corrosion resistance, and impact strength testing, which are especially important for parts in the new energy sector. These tests confirm the excellent performance and reliability of the parts under extreme conditions.

Specific Testing and Verification Processes:

Fatigue Testing:

Simulates load stress on components during prolonged use to prevent failure under tension.

Corrosion Resistance Testing:

Evaluates material resistance to corrosion for parts exposed to high humidity or aggressive environments.

Impact Testing:

Assesses the strength and durability of components under sudden impacts or high pressure.

Dimensional Verification:

Measures part accuracy using high-precision measurement systems to ensure compliance with micron-level tolerances.

Comprehensive Tracking System

Witcool employs a digital tracking system that records every stage, from raw materials to finished products, ensuring production processes can be traced at any time. This approach provides transparency in management and helps resolve potential quality issues swiftly.

Customer Feedback and Continuous Improvement

We actively consider feedback from clients in the new energy industry and continuously improve our CNC technologies. By optimizing processes and implementing the latest machining methods, Witcool guarantees the delivery of components that meet the highest quality standards.

Frequently asked questions

Witcool has extensive experience in CNC machining and is ready to offer high-precision solutions for the energy sector, ensuring quality, reliability, and innovation in every project.

What is the application of CNC in manufacturing components for new energy?

CNC is used to produce high-precision components such as wind turbine blades and solar panel parts, ensuring the reliability and durability of these systems.

What materials are used in CNC machining for new energy?

We use specialized alloys, composites, and other materials that meet industry requirements and provide high performance.

What quality standards are adhered to in the production of components for energy?

We are certified according to ISO 9001 and ISO 14001, confirming compliance with international quality and environmental standards.

How does CNC help reduce costs in production for energy projects?

The high precision of CNC reduces defects and optimizes material use, thereby lowering overall costs.

What types of energy components can be made using CNC?

We manufacture parts for solar panels, batteries, as well as components for wind turbines and energy installations.

What role does CNC play in supporting eco-friendly technologies?

CNC helps create components for renewable energy sources, supporting environmentally sustainable production.