Global Optical Lens Innovation at YTOT

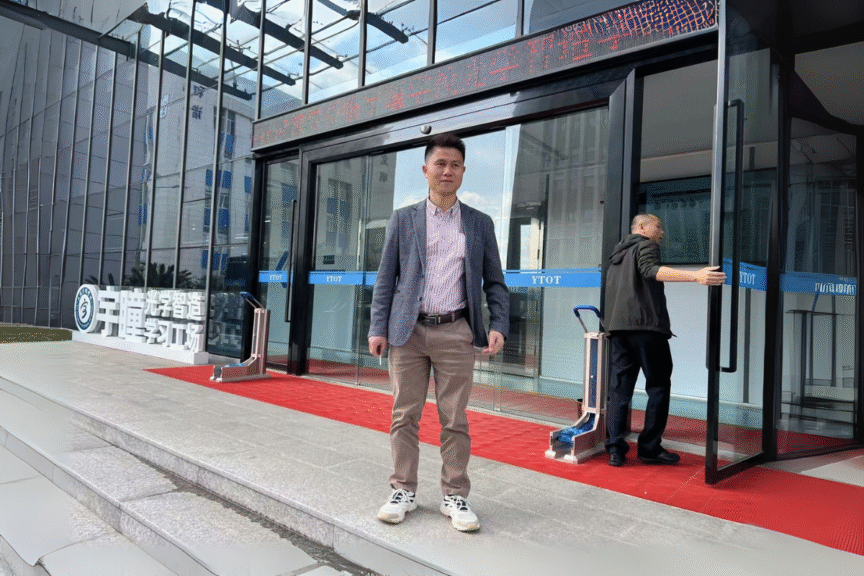

Recently, our team at Witcool Machinery had the privilege of visiting YTOT, one of the world’s leading manufacturers of optical lenses. Global Optical Lens Innovation is at the core of YTOT’s groundbreaking approach to optical lens manufacturing. In this exclusive tour, we delve into the advanced technology, precision engineering, and creative processes driving the future of vision technology.

As a CNC machining service provider, we understand the critical importance of precision and reliability in the supply chain—values that are clearly shared by YTOT in their advanced lens production, particularly in the realm of Optical Lens Manufacturing.

A Meeting of Manufacturing Excellence

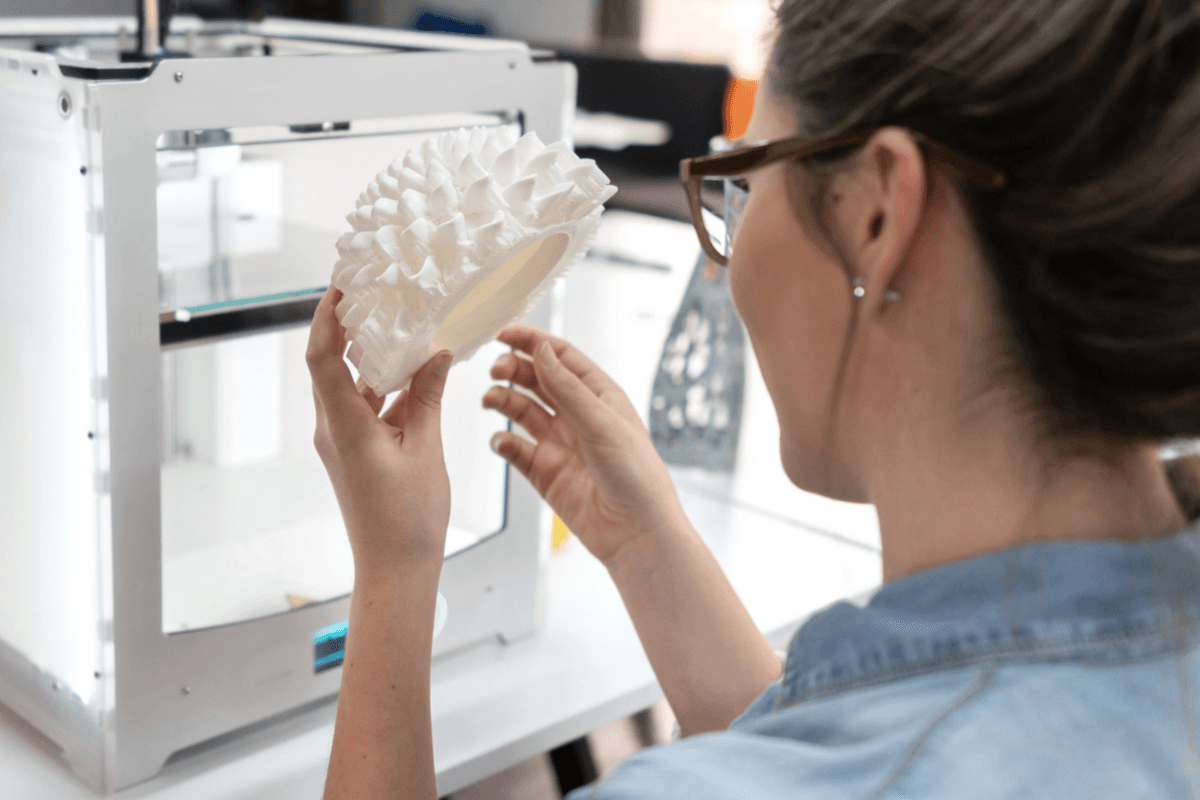

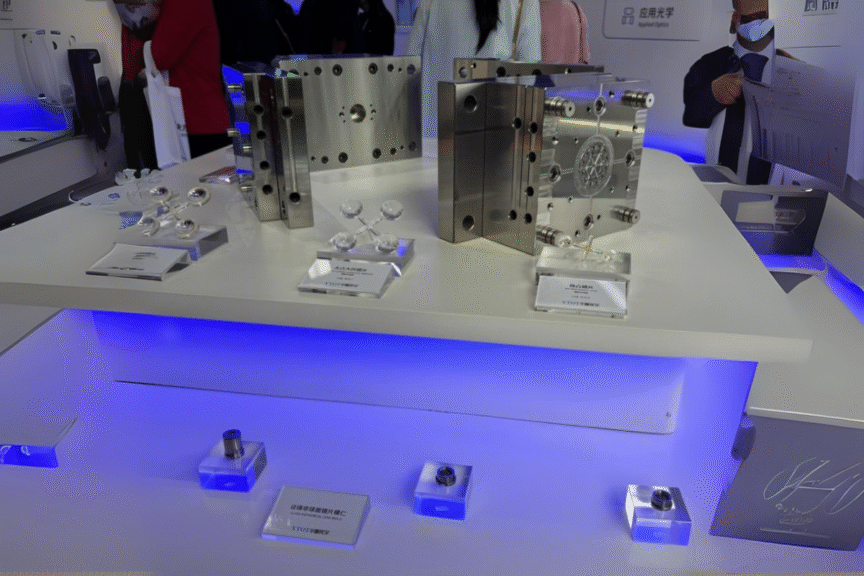

At YTOT’s state-of-the-art facility, we saw firsthand how innovation in optical lens manufacturing is closely tied to high-quality, custom-machined components. From automated assembly lines to meticulously controlled cleanrooms, every step of YTOT’s process is designed to deliver exceptional optical clarity and performance. It was inspiring to see how their success depends not just on lens design, but also on the precision of every mechanical part—many of which are produced using CNC machining, emphasizing their expertise in Optical Lens Manufacturing.

How Witcool Supports Optical Leaders

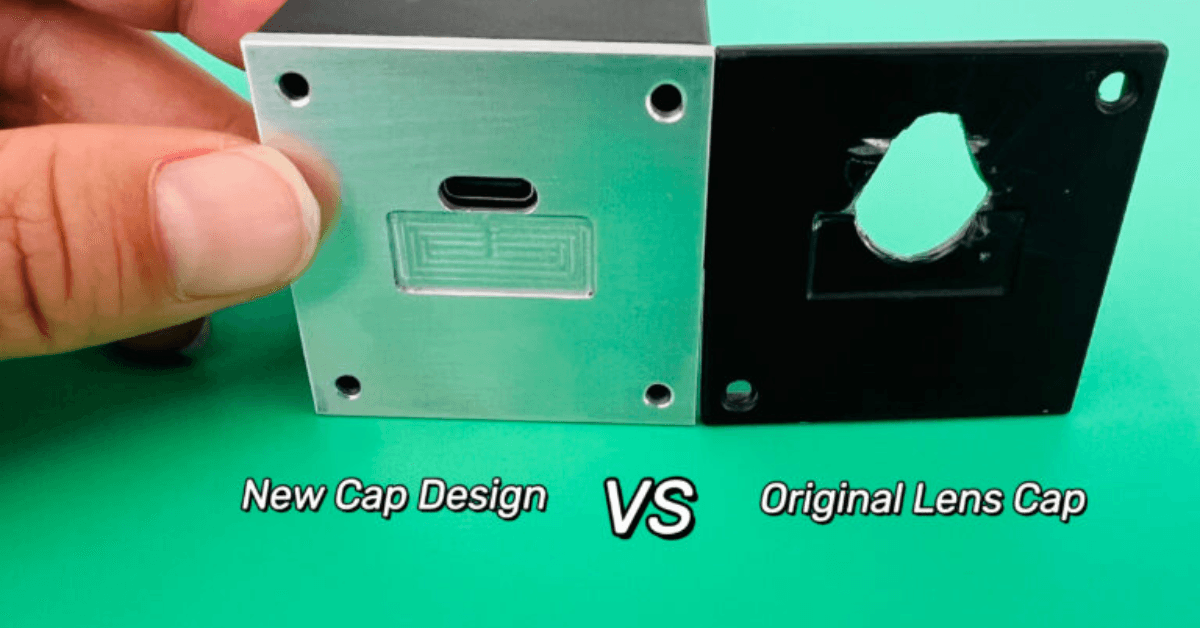

Our visit reaffirmed the importance of strong partnerships across the supply chain. At Witcool, we provide custom CNC machining services that support companies like YTOT by manufacturing high-precision parts for their equipment, tooling, and assembly lines. Our expertise in tight tolerances, complex geometries, and a variety of materials ensures that our customers in the optical industry receive components that meet the most demanding requirements.

Building the Future Together

Collaboration between CNC machining and optical lens manufacturing is vital for advancing technology in sectors such as surveillance, automotive vision, medical imaging, and machine vision. By working closely with innovative companies like YTOT, Witcool helps drive progress in both industries—delivering not only parts, but also reliable solutions that contribute to global quality standards.

We left YTOT inspired by their commitment to excellence and proud to be part of a manufacturing ecosystem where precision truly meets vision. Together, we’re helping to shape the future of optical technology—one perfectly machined component and one world-class lens at a time.