Introduction

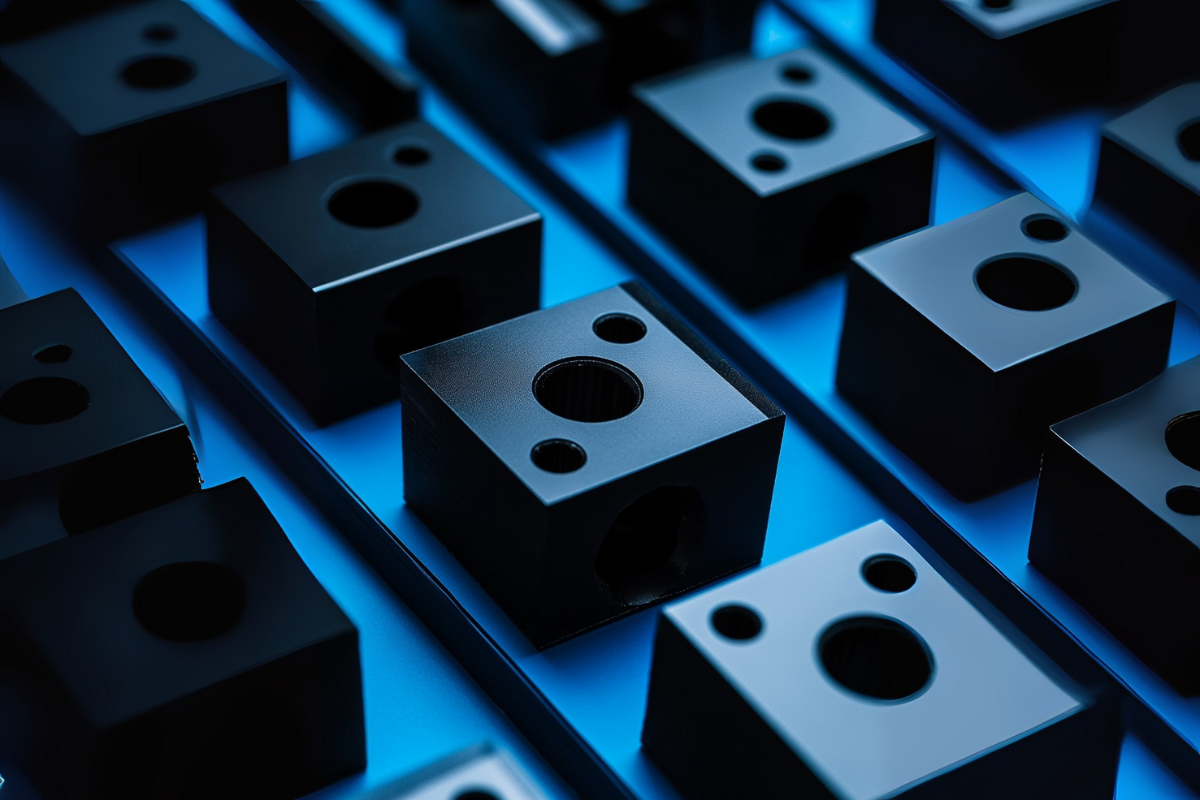

CNC (Computer Numerical Control) machining is essential in modern manufacturing for creating precise components from materials like metal, plastic, or composites. This process relies on computer-controlled tools for shaping and finishing parts, playing a crucial role in industries that demand high precision.

A key aspect of CNC machining is surface treatment, vital for enhancing both the appearance and functionality of machined parts. Among these treatments, trovalizing stands out. It’s a method where parts are polished in a tumbling barrel with abrasive media.

This process effectively removes imperfections, improves wear resistance, and provides a desirable aesthetic finish. Trovalizing, also known as barrel finishing, is particularly beneficial for softening edges, deburring, and achieving a consistent surface quality, making it indispensable for producing high-quality CNC machined components.

Overview of Trovalize Surface Treatment

Trovalizing, a critical process in CNC machining, involves polishing and smoothing components in a rotating barrel filled with abrasive media. This method enhances the surface quality of machined parts, removing imperfections and creating a uniform finish.

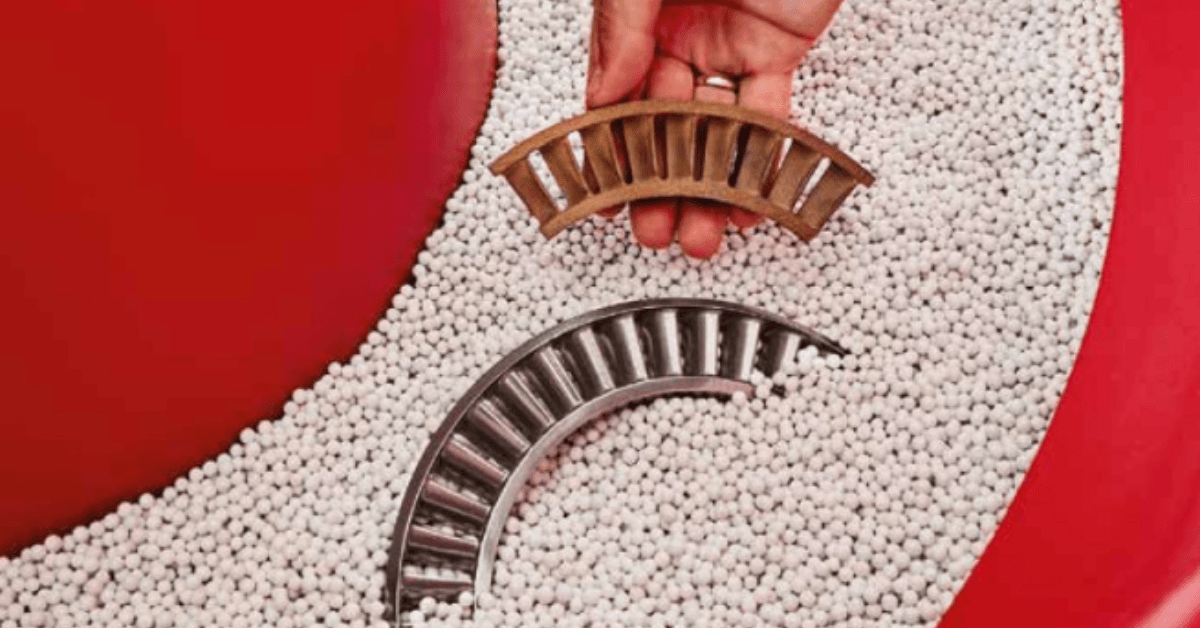

The process utilizes a barrel or vibrating container where parts are mixed with media such as ceramic pellets, steel pins, or plastic beads. The movement within the barrel, caused by rotation or vibration, enables the media to repeatedly impact the parts.

This action gently removes burrs, rounds edges, and polishes surfaces.

Different types of machinery are employed depending on the scale and requirements of the process. Smaller, bench-top tumblers are used for delicate or small batches, while larger, industrial-grade barrels cater to bulk processing. The choice of media varies based on the desired finish and material of the component, allowing customization for specific applications in CNC machining.

Trovalizing is efficient, cost-effective, and adaptable, making it a preferred surface treatment method for a variety of CNC machined parts.

Enhanced Aesthetic Appeal

Trovalizing significantly elevates the visual quality of CNC machined parts. By uniformly polishing surfaces, it imparts a smooth and refined finish that is visually appealing. This process is particularly important for components where aesthetic value is as crucial as functional integrity.

For instance, in consumer electronics, where sleek and smooth surfaces are a key selling point, trovalizing ensures a high-end finish. Similarly, in the automotive industry, visible engine parts and interior components benefit from the enhanced appearance provided by trovalizing, contributing to the overall aesthetic and perceived quality of the vehicle.

Improved Wear Resistance

Trovalizing enhances the wear resistance of CNC machined parts. This surface treatment process compacts the material’s surface, making it more resilient to physical stresses such as friction, impact, and abrasion. As a result, components that undergo trovalizing exhibit a longer lifespan and greater durability in demanding applications.

This improved wear resistance is particularly beneficial in sectors like aerospace and automotive, where parts are regularly subjected to high stress and need to maintain their integrity over time. Trovalizing ensures these components can withstand prolonged use, reducing the frequency of replacements and maintenance.

Removal of Burrs and Sharp Edges

Trovalizing plays a crucial role in deburring and rounding sharp edges on CNC machined parts. During this process, the abrasive action of the media in the tumbling barrel effectively smooths out irregularities and sharpness. This results in safer, more user-friendly components with reduced risk of injury or wear on adjoining parts.

Smooth edges are essential for the functionality and safety of machinery, particularly in high-contact applications like automotive assemblies and consumer appliances. Trovalizing ensures these edges are uniformly treated, maintaining the integrity and safety of the final product.

Uniformity and Consistency in Finishing

Trovalizing ensures a high degree of uniformity and consistency in the finishing of CNC machined parts. By processing multiple parts simultaneously in a controlled environment, it guarantees that each component receives an identical level of abrasion and polishing. This uniform treatment is critical in industrial applications where consistent quality and appearance across all parts are paramount.

In industries like aerospace and medical devices, where even minor variations can significantly impact performance and safety, the consistency provided by trovalizing is invaluable. It assures that every part meets stringent quality standards, maintaining the reliability and reputation of the final products.

Cost-Effectiveness of Trovalizing

Trovalizing stands out for its cost-effectiveness compared to other surface treatments. It offers economical processing for large batches, reducing per-part cost significantly.

The long-term durability and quality achieved through trovalizing also diminish the need for frequent replacements and maintenance, leading to substantial financial savings over time.

Case Study: Witcool’s Custom Project for 500 Sets of Parts

A client approached Witcool with a request for 500 sets of parts, specifically asking for trovalizing treatment. The client’s primary goal was to enhance the smoothness and durability of these components.

Witcool successfully executed the order, applying trovalizing to meet the client’s specifications. The treated parts exhibited significantly improved surface quality and longevity, fulfilling the customer’s requirements for both aesthetic appeal and functional resilience.

This project exemplifies Witcool’s capability to deliver customized solutions with precise surface treatment, catering to the specific needs of their clients.

Witcool successfully executed the order, applying trovalizing to meet the client’s specifications. The treated parts exhibited significantly improved surface quality and longevity, fulfilling the customer’s requirements for both aesthetic appeal and functional resilience.

Conclusion

Trovalize surface treatment significantly enhances CNC machined components. Key benefits include:

- Improved Aesthetics: Achieves a smooth and visually appealing finish.

- Enhanced Durability: Increases wear resistance, extending component lifespan.

- Uniform Finish: Ensures consistent quality across all treated parts.

- Safety and Functionality: Removes sharp edges and burrs, promoting safer and more effective usage.

These benefits underscore trovalizing’s critical role in improving the quality and performance of CNC machined parts.

When considering trovalizing for your CNC machining projects, turn to Witcool. As a professional manufacturer of hardware parts, we specialize in providing top-quality trovalizing services that meet your specific needs. Trust Witcool for reliable and expert solutions in CNC machining.

FAQs

Q: What is Trovalizing in CNC Machining?

A: Trovalizing is a surface finishing process in CNC machining where parts are polished using a barrel or vibratory method with abrasive media. It enhances surface smoothness, durability, and aesthetic appeal of the machined parts.

Q: How Does Trovalizing Differ from Other Surface Finishing Techniques?

A: Unlike anodizing or powder coating, which involve chemical or electrostatic processes, trovalizing is a mechanical method that physically smooths surfaces. It’s particularly effective for deburring, edge rounding, and achieving a uniformly polished finish.

Q: What Types of Materials Can Be Trovalized?

A: Trovalizing is suitable for a wide range of materials, including metals like aluminum, steel, brass, and plastics. The key is choosing the right media and process parameters for the specific material to avoid damage and achieve the desired finish.

Q: What Industries Benefit Most from Trovalized CNC Parts?

A: Industries such as aerospace, automotive, medical devices, and consumer electronics benefit significantly from trovalized parts due to the process’s ability to enhance durability, appearance, and functionality of components.

Q: How Does Trovalizing Impact the Longevity and Wear of CNC Parts?

A: Trovalizing compresses and smooths the surface, which reduces friction and resistance to wear. This results in CNC parts that are more durable and have a longer operational lifespan, especially in high-stress applications.

Q: What Should I Consider When Requesting a Quote for Trovalizing Services?

A: When requesting a quote, consider the material type, part dimensions, desired surface finish quality, quantity, and any specific requirements like deburring or edge rounding. Providing detailed information ensures an accurate quote and optimal results.