Qu'est-ce que le revêtement en Téflon ?

Revêtement en téflonLe PTFE (polytétrafluoroéthylène), également connu sous le nom de revêtement, est un revêtement fluoropolymère haute performance reconnu pour ses propriétés antiadhésives, antifriction et de résistance chimique exceptionnelles. Découvert par DuPont en 1938, le Téflon est devenu une solution incontournable dans de nombreux secteurs pour améliorer les performances et la durabilité des composants.

Chez Witcool, nous appliquons des revêtements en Téflon sur des pièces usinées CNC, des composants en tôle et des prototypes imprimés en 3D pour répondre à des exigences de performances strictes.

Propriétés physiques

1. Densité : 2,1-2,3 g/cm³

2. Point de fusion : 327℃ (620,6℉), mais se détériore au-dessus de 260℃ (500℉)

3. Coefficient de frottement : inférieur ou égal à 0,1, le plus petit coefficient de frottement connu pour un matériau solide

4. Taux d'absorption d'eau : <0,01% (23℃, 24h)

5. Résistance à la traction : 22-35 MPa

6. Allongement à la rupture : 200-400%

7. Énergie de surface : Très faible, l'un des matériaux ayant la plus faible énergie de surface parmi les matériaux solides

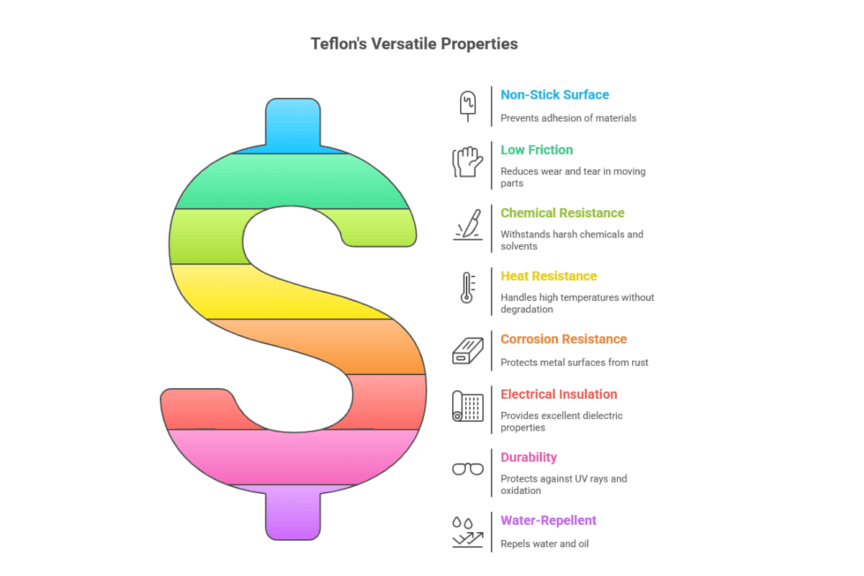

Principales propriétés du revêtement en téflon

Pourquoi le revêtement Téflon est-il si populaire ? Voici ses principales caractéristiques :

- Surface antiadhésiveLa faible énergie de surface du Téflon le rend incroyablement antiadhésif, empêchant les matériaux tels que les adhésifs, les huiles ou les débris d'adhérer aux pièces revêtues. Il est idéal pour les applications dans la transformation des aliments, l'emballage ou les équipements médicaux.

- Faible frottement:Avec l'un des coefficients de frottement les plus bas parmi les matériaux solides, le Téflon réduit l'usure, ce qui le rend parfait pour les pièces mobiles dans les systèmes robotiques ou automobiles.

- Résistance chimique:Le Téflon résiste à l'exposition aux produits chimiques agressifs, aux acides et aux solvants, garantissant ainsi sa longévité dans des environnements difficiles comme l'aérospatiale ou les machines industrielles.

- Résistance à la chaleur:Il peut supporter des températures allant jusqu'à 260 °C (500 °F) sans se dégrader, ce qui le rend adapté aux applications à haute température.

- Résistance à la corrosion:Le téflon protège les surfaces métalliques de la rouille et de la corrosion, prolongeant ainsi la durée de vie des composants.

- Isolation électrique:Ses excellentes propriétés diélectriques en font un choix de premier ordre pour l’électronique et les appareils médicaux.

- Durabilité:Protège contre les rayons UV, l’oxydation et la corrosion, prolongeant ainsi la durée de vie des composants.

- Hydrofuge :Repousse l’eau et l’huile, ce qui le rend idéal pour les tissus ou les pièces exposées à l’humidité.

Applications du revêtement en téflon

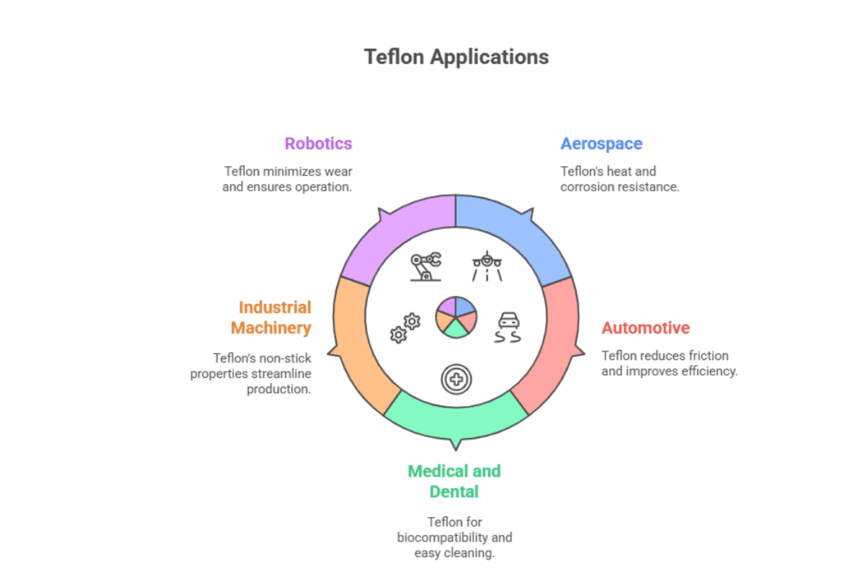

Chez Witcool, nous servons les industries qui exigent précision et durabilité. Voici comment le revêtement Téflon améliore les composants dans divers secteurs :

- Aérospatiale:Les pales de turbine, les fixations et autres composants bénéficient de la résistance à la chaleur et à la corrosion du Téflon, garantissant ainsi la fiabilité dans des conditions extrêmes.

- Automobile:Les pièces de moteur, les engrenages et les roulements utilisent du Téflon pour réduire la friction et améliorer le rendement énergétique.

- Médical et dentaire:Les outils chirurgicaux et les implants sont recouverts de Téflon pour une biocompatibilité et un nettoyage facile.

- Machines industrielles:Les bandes transporteuses, les moules et les rouleaux exploitent les propriétés antiadhésives du Téflon pour rationaliser la production.

- Robotique:Les pièces mobiles des systèmes robotiques utilisent du Téflon pour minimiser l'usure et assurer un fonctionnement fluide.

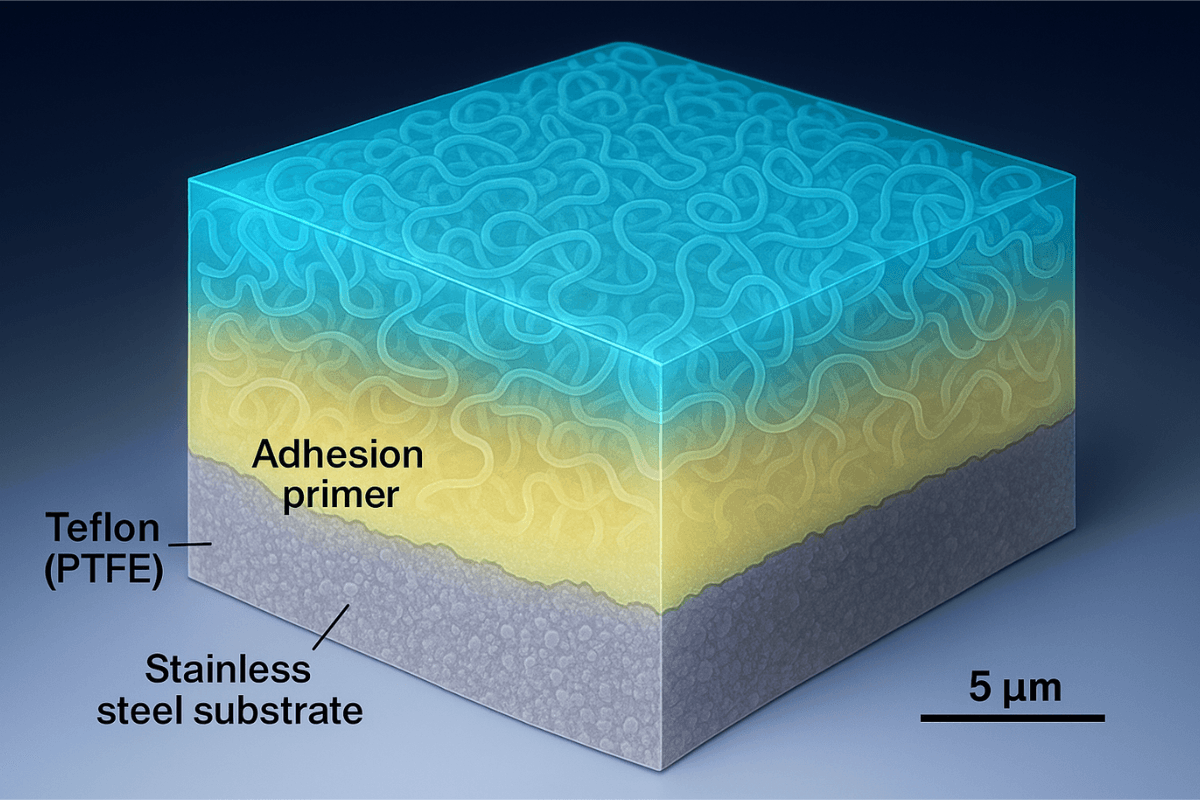

Comment le revêtement en Téflon est-il appliqué ?

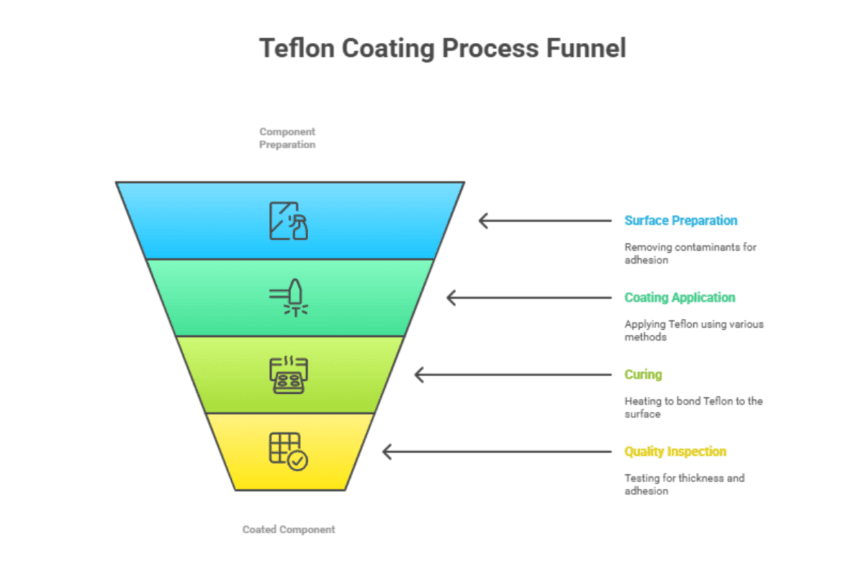

- Préparation de la surface: Le composant (qu'il soit usiné CNC, en tôle ou imprimé en 3D) est soigneusement nettoyé pour éliminer les huiles, la saleté et les contaminants. Cela garantit une bonne adhérence du revêtement.

- Application de revêtement:Le téflon est appliqué à l'aide de méthodes telles que le revêtement par pulvérisation, le revêtement par immersion ou le revêtement électrostatique, en fonction de la géométrie et des exigences de la pièce.

- Durcissement:La pièce revêtue est chauffée dans un environnement contrôlé pour lier le Téflon à la surface, créant une couche durable et uniforme.

- Inspection de la qualité:Nous testons rigoureusement la pièce revêtue pour garantir qu'elle répond à vos spécifications en matière d'épaisseur, d'adhérence et de performances.

Notre installation ultramoderne à Dongguan garantit la précision à chaque étape, que nous travaillions sur des prototypes ou sur une production de masse pour des clients en Europe, aux États-Unis, au Vietnam ou au-delà.

Avantages du revêtement en téflon pour vos projets

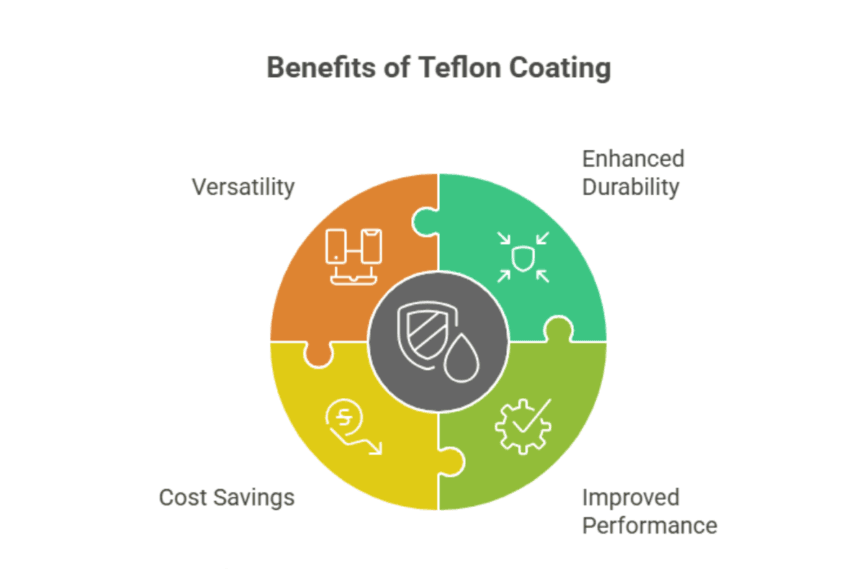

Choisir le revêtement Téflon pour vos composants offre plusieurs avantages :

- Durabilité améliorée:Protège les pièces de l’usure, de la corrosion et des dommages chimiques, prolongeant ainsi leur durée de vie.

- Performances améliorées:Réduit la friction et le collage, ce qui permet un fonctionnement plus fluide et moins d'entretien.

- Économies de coûts:En minimisant l’usure, les revêtements en Téflon réduisent le besoin de remplacements ou de réparations fréquents.

- Versatilité:Convient à une large gamme de matériaux, y compris les métaux, les plastiques et les composites, ce qui le rend idéal pour l'usinage CNC personnalisé et la fabrication de tôles.

Précautions d'emploi

Limites de température :

• Limite de température élevée : Il est préférable de ne pas dépasser 260 °C en cas d'utilisation continue, car le dépassement de cette température peut provoquer une décomposition et libérer des gaz nocifs.

• Attention aux basses températures : l'impact de forces externes dans des environnements à très basse température (inférieures à -196 °C) peut rendre le revêtement cassant.

Prévention des dommages physiques :

• Évitez d’utiliser des objets pointus pour rayer la surface du revêtement.

• Empêche les frottements et l’usure excessifs, en particulier dans les applications à forte charge.

Contact chimique :

• Bien que résistant à la plupart des produits chimiques, une exposition prolongée à des environnements extrêmes tels que des concentrations élevées d'acide fluorhydrique ou d'acide sulfurique concentré chaud peut causer des dommages.

• Certains solvants organiques spéciaux peuvent affecter les performances du revêtement.

Nettoyage et entretien :

• Nettoyer avec des détergents doux et des chiffons doux.

• Évitez d’utiliser des produits de nettoyage contenant des particules grossières ou des produits chimiques fortement corrosifs.

• Assurez-vous qu'il n'y ait aucun résidu de produits de nettoyage après le nettoyage.

Pourquoi choisir Witcool pour les pièces revêtues de Téflon ?

Depuis sa création en 2007, Witcool est un partenaire de confiance pour les industries exigeant une fabrication de haute précision. Voici pourquoi nous sommes le choix idéal pour vos composants revêtus de Téflon :

- Compétence:Notre équipe est spécialisée dans l'usinage CNC, la fabrication de tôles et l'impression 3D, garantissant une intégration transparente des revêtements en Téflon dans votre projet.

- Personnalisation:Nous travaillons à partir de vos dessins ou échantillons pour vous proposer des solutions sur mesure, que ce soit pour des prototypes ou des productions à grande échelle.

- Portée mondiale:Nous sommes fiers de servir des clients aux États-Unis, en Europe, au Japon et ailleurs, avec une expérience éprouvée en matière de qualité et de fiabilité.

- Solutions uniques:De la conception à la finition, nous gérons chaque étape en interne, garantissant un délai d'exécution rapide et une qualité constante.

Prêt à explorer le revêtement en téflon pour votre prochain projet ?

Le revêtement Téflon est un moyen efficace d'améliorer les performances et la longévité de vos composants, et chez Witcool, nous sommes là pour vous aider. Que vous soyez dans l'aéronautique, l'automobile, le médical ou la robotique, notre équipe est prête à vous fournir des pièces revêtues de précision qui répondent parfaitement à vos spécifications.

Entrer en contact: Visite www.wit.cool Pour en savoir plus sur nos services, suivez-nous sur LinkedIn, Facebook ou Xing, ou contactez-nous directement pour discuter de votre projet. Donnons vie à vos idées grâce à la puissance du revêtement Téflon !

Vous avez des questions sur le revêtement Téflon ou d'autres traitements de surface ? Envoyez-nous un message et nous serons ravis de vous guider !

FAQ

Q : Sur quels matériaux peut-on appliquer un revêtement en Téflon ?

R : Le revêtement Téflon est compatible avec les métaux (aluminium, acier, titane, etc.), les plastiques (nylon, ABS, PEEK) et les composites comme la fibre de carbone. Witcool adapte ses revêtements aux besoins spécifiques de chaque matériau.

Q:

R : Le Téflon reste stable de -200 °C à 260 °C (-328 °F à 500 °F) ; au-delà de 260 °C, il peut se dégrader et en dessous de -196 °C, il peut devenir cassant. Witcool peut adapter ses formulations aux températures extrêmes.

Q : Combien de temps dure le processus de revêtement en Téflon ?

R : Le revêtement prend de 1 à 3 jours ouvrés selon la taille du lot (1 à 100 pièces : environ 1 jour ; plus de 1 000 pièces : environ 3 jours), avec des options accélérées. La qualité est garantie par le nettoyage, l'application précise, le durcissement et des tests rigoureux.

Q : Combien de temps dure le revêtement en Téflon et comment est-il entretenu ?

A: L

Q : Quels sont les facteurs qui influencent le coût du revêtement en Téflon ?

R : Les coûts dépendent de la taille de la pièce, du volume du lot, de la complexité de la géométrie, de la préparation de la surface, des spécifications du revêtement et des exigences de contrôle qualité. Contactez Witcool pour obtenir des devis personnalisés.

Q : Le revêtement en Téflon présente-t-il des risques environnementaux ?

R : La production et la dégradation du Téflon au-dessus de 260 °C peuvent libérer des substances nocives comme les PFAS, nécessitant une manipulation et une élimination appropriées. Witcool respecte les réglementations environnementales et propose des revêtements écologiques lorsque cela est possible.