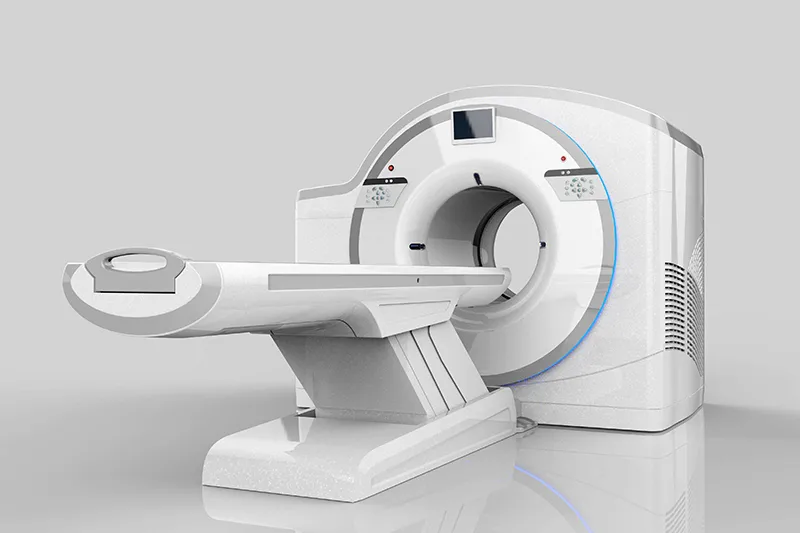

Usinage CNC de précision pour équipements médicaux

L'usinage CNC de haute précision garantit la création de composants complexes pour équipements médicaux avec une précision et une qualité exceptionnelles, minimisant les erreurs et garantissant la fiabilité et la durabilité des pièces.

- Géométries complexes et finitions cosmétiques

- Devis instantané avec analyse DFM complète

- Certifications spécialisées et documentation qualité

Confiance de la part de

Pourquoi choisir Witcool CNC pour l'équipement médical ?

Witcool propose des services professionnels d'usinage CNC pour les équipements médicaux, offrant une précision jusqu'à 0,001 mm et une fiabilité de niveau 99,9%. Nos technologies sont conformes aux normes strictes ISO 13485, garantissant une qualité et une sécurité élevées des composants.

Les dispositifs médicaux nécessitent des pièces complexes et extrêmement précises pour garantir des performances fiables et minimiser les risques pour les patients. Witcool soutient le développement de l'industrie médicale en créant des pièces qui améliorent la fonctionnalité et la durabilité des équipements, contribuant ainsi à l'innovation dans les technologies médicales.

Services et solutions

Witcool est spécialisé dans la production de pièces sur mesure pour les dispositifs médicaux, en utilisant un système de devis avancé pour accélérer le développement. Des innovations biotechnologiques aux dispositifs d'imagerie ou aux gabarits et montages, nous proposons des solutions de haute qualité avec des capacités de production étendues pour soutenir vos avancées dans le domaine de la santé.

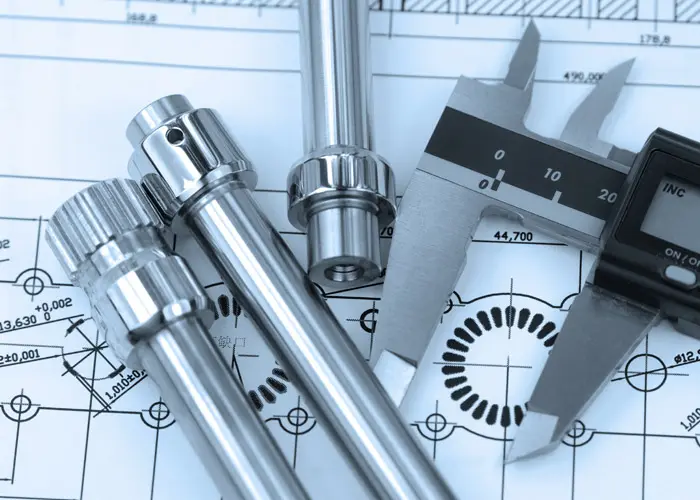

Usinage CNC

Création de structures précises et complexes par fraisage, tournage et post-traitement, parfaitement adaptées aux prototypes complexes et aux pièces métalliques fonctionnelles.

Coulée sous pression

Production rapide de pièces moulées et d'outillages intermédiaires, optimisés pour la production en série avec une qualité constante.

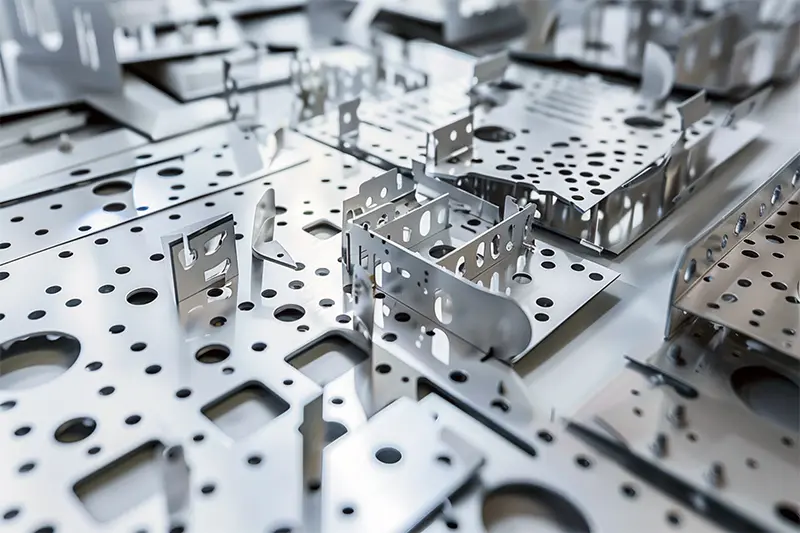

Traitement de la tôle

Offre une flexibilité dans la formation de composants métalliques précis pour diverses applications, garantissant à la fois adaptabilité et précision.

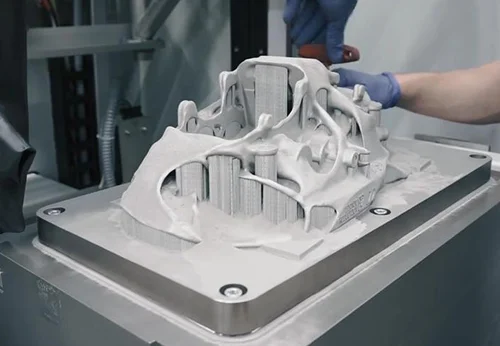

Impression 3D

Un processus rapide et polyvalent qui permet la création rapide de formes complexes à partir d'une variété de matériaux, idéal pour des conceptions innovantes.

Matériaux et finitions de surface

Matériels

Nous proposons une large gamme de matériaux, notamment des métaux, des plastiques et des composites.

Finition de surface

Notre finition de haute qualité améliore la durabilité et l'apparence des pièces, répondant aux exigences des surfaces lisses et texturées.

Expérience dans la fabrication d'équipements médicaux

Avec des années d'expérience dans l'industrie des équipements médicaux, Witcool Machining a collaboré avec succès avec des entreprises telles que Siemens Healthineers et Philips Healthcare, fournissant des composants de haute précision qui répondent aux normes strictes de l'industrie.

« Witcool a fait preuve d’un haut niveau de professionnalisme et de précision dans l’usinage des composants de nos équipements. Leurs technologies avancées et leur contrôle qualité strict ont assuré une grande fiabilité et le respect de nos exigences. Ils sont devenus un partenaire de confiance et nous espérons poursuivre cette collaboration fructueuse. »

Usinage CNC de composants pour Siemens Healthineers

Witcool Machining a produit avec succès des composants pour les équipements médicaux de Siemens Healthineers, notamment des pièces pour les systèmes de diagnostic. Nous avons utilisé des technologies CNC avancées pour atteindre une précision allant jusqu'à 0,002 mm et appliqué des matériaux biocompatibles. Le projet comprenait le fraisage, le tournage et le perçage, ce qui a permis d'obtenir des pièces de haute qualité et fiables. Tous les composants ont subi des tests rigoureux de résistance et de précision, confirmant leur conformité aux normes internationales.

1. Fraisage de haute précision

2. Tournage avec tolérances minimales

3. Perçage pour un assemblage précis

● Précision atteinte jusqu'à 0,002 mm.

● Conformité aux normes ISO 13485.

● Projet terminé sans défaut.

« Leur expertise en usinage CNC nous a permis de recevoir des pièces entièrement conformes à nos exigences. Nous apprécions leur capacité à résoudre des problèmes complexes et à fournir des produits de haute qualité. Witcool a fait ses preuves en tant que partenaire fiable et nous sommes impatients de poursuivre notre collaboration à l’avenir. »

Composants de fabrication pour les appareils médicaux Philips

Witcool Machining a réalisé l'usinage CNC de pièces pour des appareils médicaux Philips, notamment des composants pour des systèmes à ultrasons et à rayons X. Nous avons utilisé des méthodes d'usinage de haute précision, telles que le fraisage et le tournage, pour garantir une conformité parfaite aux spécifications techniques. Toutes les pièces ont été fabriquées à partir d'alliages médicaux et ont subi des tests rigoureux de qualité et de fiabilité. Le projet a été achevé dans les délais et dans son intégralité, prouvant notre capacité à gérer des commandes complexes.

1. Fraisage de précision

2. Tournage de haute qualité

3. Tests de conformité aux normes médicales

● Production réussie de pièces complexes

● Conformité totale aux exigences de Philips

● Résultats positifs de tous les tests de qualité

Avantages de l'équipement médical avec usinage CNC

L'usinage CNC offre une précision inégalée, rationalisant la production en minimisant les erreurs et les déchets tout en réduisant considérablement les délais et les coûts de fabrication. Sa capacité à répondre aux normes industrielles strictes garantit fiabilité et cohérence, ce qui en fait la solution parfaite pour la fabrication de composants médicaux complexes avec des performances et une sécurité de haute qualité.

Productivité accrue

L’usinage de haute qualité et le respect de normes strictes contribuent à garantir la sécurité et la fiabilité des composants.

Précision améliorée

L'usinage CNC atteint une précision allant jusqu'à 0,01 mm, ce qui est essentiel pour la production de composants médicaux où même des écarts minimes peuvent entraîner des problèmes importants.

Réduction des coûts

L'usinage CNC permet une utilisation efficace des matériaux et minimise les déchets. La programmation des processus permet un contrôle précis de l'utilisation des matériaux, réduisant ainsi les coûts de production.

Flexibilité et évolutivité

Les technologies CNC facilitent la modification des dessins de conception et l'adaptation de la fabrication aux exigences changeantes, rendant les processus de développement et de prototypage plus flexibles et adaptables.

Assurance qualité

Witcool garantit les plus hauts niveaux de précision et le respect total de toutes les normes de qualité à chaque phase de production. En adhérant aux normes internationales, notamment ISO 9001, nous fabriquons des composants fiables pour l'industrie des équipements médicaux. Notre contrôle qualité rigoureux et nos tests approfondis garantissent que chaque produit répond aux exigences exigeantes du secteur médical, garantissant ainsi une fiabilité opérationnelle durable.

Usinage de précision et contrôle qualité

Dans le secteur des équipements médicaux, l'usinage CNC joue un rôle essentiel dans la production de composants critiques tels que les outils de diagnostic, les instruments chirurgicaux et les pièces structurelles. Witcool applique des mesures de contrôle qualité strictes à chaque étape de la production, garantissant que chaque pièce répond aux tolérances les plus strictes. Nous avons mis en place un système de gestion de la qualité totale (TQM), qui nous permet de surveiller chaque étape de production en temps réel, réduisant ainsi les défauts et minimisant les erreurs. Des machines à mesurer tridimensionnelles (CMM) et des systèmes de mesure optique sont utilisés pour maintenir la précision à chaque étape.

processus de contrôle qualité :

Contrôle des matières premières :

Avant le début de la production, tous les matériaux sont soumis à des inspections rigoureuses pour garantir leur conformité aux normes de conception et aux normes de l’industrie.

Inspection en cours de fabrication :

À chaque étape critique de la production, des points de contrôle sont mis en œuvre pour éviter l’accumulation d’erreurs et assurer le respect des spécifications.

Inspection finale et vérification :

Une fois la production terminée, des contrôles approfondis des dimensions, de la qualité de surface et des tolérances sont effectués pour garantir le respect total des exigences techniques.

- Ces processus assurent une qualité maximale à chaque étape, garantissant la fiabilité du produit final.

Certification et normes de l'industrie

Nos opérations de fabrication sont certifiées ISO 9001, ce qui garantit que tous les composants sont conformes aux normes de qualité mondiales. De plus, nos matériaux et nos processus sont conformes aux réglementations industrielles essentielles telles que RoHS et REACH, garantissant ainsi le respect des normes environnementales et de sécurité.

Normes relatives aux matériaux et aux procédés

Les composants des équipements médicaux exigent une résistance et une précision exceptionnelles des matériaux. Witcool sélectionne des matériaux conformes aux spécifications de l'industrie, tels que l'acier inoxydable, les alliages d'aluminium et le titane, et applique des paramètres d'usinage optimisés pour répondre aux spécifications requises.

Test et vérification des produits

À chaque étape du processus de production, Witcool effectue des tests et des validations complets, notamment des tests de fatigue, de résistance à la corrosion et de résistance aux chocs, qui sont essentiels pour les pièces d'équipement médical. Ces évaluations confirment les performances et la fiabilité exceptionnelles des composants dans des conditions extrêmes.

Processus spécifiques de test et de vérification :

Essais de fatigue :

Simule la contrainte de charge sur les composants lors d'une utilisation prolongée pour éviter toute défaillance sous tension.

Essais de résistance à la corrosion :

Évalue la résistance des matériaux à la corrosion pour les pièces exposées à une humidité élevée ou à des environnements agressifs.

Essais d'impact :

Évalue la résistance et la durabilité des composants soumis à des impacts soudains ou à une pression élevée.

Vérification dimensionnelle :

Mesure la précision des pièces à l'aide de systèmes de mesure de haute précision pour garantir la conformité avec les tolérances au niveau du micron.

Système de suivi complet

Witcool utilise un système de suivi numérique qui enregistre chaque étape, des matières premières aux produits finis, ce qui permet de retracer les processus de production à tout moment. Cette approche assure une gestion transparente et permet de résoudre rapidement les problèmes potentiels de qualité.

Commentaires des clients et amélioration continue

Nous intégrons systématiquement les retours de nos clients du secteur des équipements médicaux et nous efforçons d'affiner nos technologies CNC. En améliorant continuellement nos processus et en intégrant les dernières techniques d'usinage, Witcool garantit la livraison de composants répondant aux critères de qualité les plus élevés.

Questions fréquemment posées

Witcool possède une vaste expérience dans l'usinage CNC et est prêt à offrir des solutions de haute précision pour l'industrie médicale, garantissant qualité, fiabilité et innovation dans chaque projet.

Quels sont les principaux matériaux utilisés dans l’usinage CNC médical ?

Les matériaux courants comprennent acier inoxydable, titane, et COUP D'OEILL'acier inoxydable est très durable et résistant à la corrosion, souvent utilisé pour les instruments chirurgicaux. Le titane est biocompatible et idéal pour les implants, tandis que le PEEK est privilégié pour sa solidité et sa résistance à la stérilisation dans les prothèses et les dispositifs chirurgicaux.

Pourquoi l’usinage CNC est-il privilégié pour les dispositifs médicaux ?

L'usinage CNC garantit haute précision, la répétabilité et la capacité à répondre à des normes strictes de biocompatibilité. Il est essentiel pour créer des géométries complexes dans les outils médicaux, les implants et les équipements de diagnostic.

Quels sont les avantages de l’usinage CNC pour les pièces médicales personnalisées ?

Il offre une flexibilité dans la création implants personnalisés et des outils adaptés aux besoins des patients. L'usinage CNC permet également un prototypage rapide pour des conceptions innovantes.

Comment l'usinage CNC répond-il à des normes médicales strictes ?

Les fabricants adhèrent à des normes telles que ISO 13485, garantissant des systèmes rigoureux de gestion de la qualité des dispositifs médicaux. Cela garantit le respect des exigences de sécurité et réglementaires.

Quels sont les défis rencontrés dans l’usinage CNC pour les applications médicales ?

Les exigences de précision, la biocompatibilité des matériaux et le maintien de la propreté pendant la production sont des défis majeurs. Des logiciels avancés comme Mastercam permettent de répondre à ces exigences avec une grande précision et une grande efficacité.

Quelles sont les avancées réalisées dans l’usinage CNC médical ?

Les innovations incluent Technologie Dynamic Motion™ pour un usinage optimisé et l'utilisation de logiciels de CAO/FAO pour traiter efficacement des conceptions complexes. Les machines CNC compactes avec des fonctions d'usinage propres sont également de plus en plus utilisées dans les laboratoires médicaux.