Usinage CNC expert pour l'industrie de l'énergie

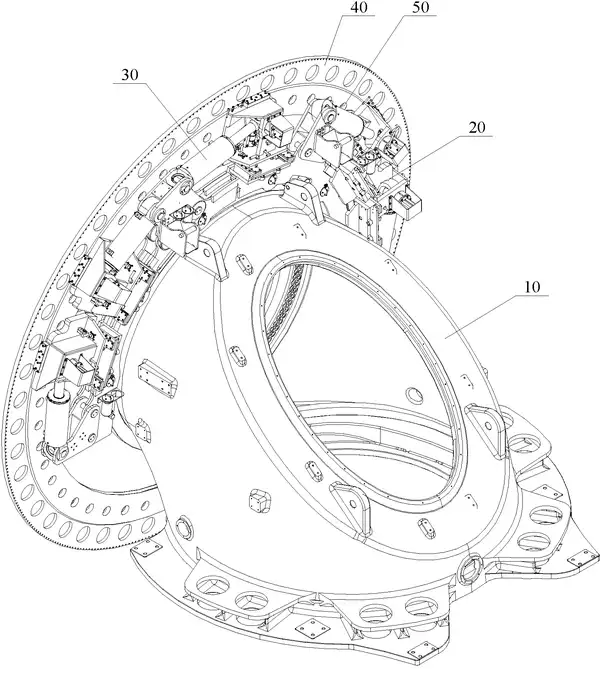

Witcool propose des solutions de haute précision pour le secteur de l'énergie, en utilisant l'usinage CNC 5 axes pour fabriquer des composants de turbines, des générateurs et d'autres équipements. Nous garantissons le respect de normes strictes de qualité et de durabilité, garantissant des performances fiables des équipements sous des charges accrues.

- Assure des tolérances minimales et une haute précision.

- Réduit les déchets et accélère la production.

- Garantit la répétabilité dans la production de masse.

Confiance de la part de

Pourquoi choisir Wticool CNC

Chez Witcool, nous utilisons des technologies d'usinage CNC de pointe pour offrir une précision et une fiabilité exceptionnelles. Nous assurons un contrôle qualité rigoureux à chaque étape et livrons les projets rapidement, ce qui fait de nous un partenaire de confiance pour les projets complexes.

Engagement en faveur du développement durable

Witcool s'engage à adopter des pratiques durables à tous les niveaux. Nous utilisons des matériaux respectueux de l'environnement, intégrons des processus économes en énergie et nous efforçons activement de réduire les émissions de carbone. Nos initiatives en matière de développement durable comprennent la réduction des déchets et l'optimisation de la consommation d'énergie, conformément à nos objectifs à long terme.

Notre engagement envers la qualité est soutenu par des tests et des certifications rigoureux tels que ISO, garantissant la conformité et dépassant les normes de l'industrie.

Solutions sur mesure

Nous proposons des solutions personnalisées pour répondre aux exigences spécifiques des projets d'énergie solaire, telles que des services d'usinage sur mesure pour des composants uniques ou des capacités de fabrication flexibles adaptables à différentes échelles et besoins. Notre concentration sur les objectifs du client garantit la précision et la livraison dans les délais.

Des prix compétitifs et de la valeur

Nous proposons des prix compétitifs tout en privilégiant la valeur globale. Nos solutions englobent les économies de coûts, la durabilité, l'efficacité et la haute performance des produits, aidant ainsi les clients à minimiser les coûts opérationnels. La fabrication flexible optimise les projets pour des avantages maximaux.

Un service client exceptionnel

Notre engagement envers un service client exceptionnel comprend des réponses rapides, une assistance à la planification du projet et un soutien continu tout au long du cycle de vie du projet. Cette approche centrée sur le client nous distingue sur un marché concurrentiel et garantit la confiance dans des solutions rapides et de haute qualité.

Fabrication de composants énergétiques

Notre savoir-faire en matière d'usinage CNC nous permet de garantir une qualité et des performances exceptionnelles lors de la production de composants critiques pour le secteur de l'énergie. Nous comprenons les défis et les exigences uniques du secteur de l'énergie et proposons des solutions qui répondent aux normes industrielles les plus strictes.

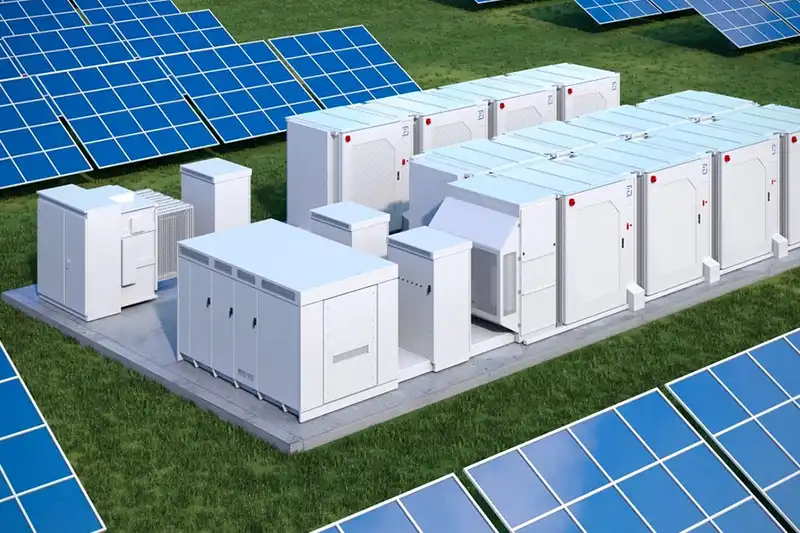

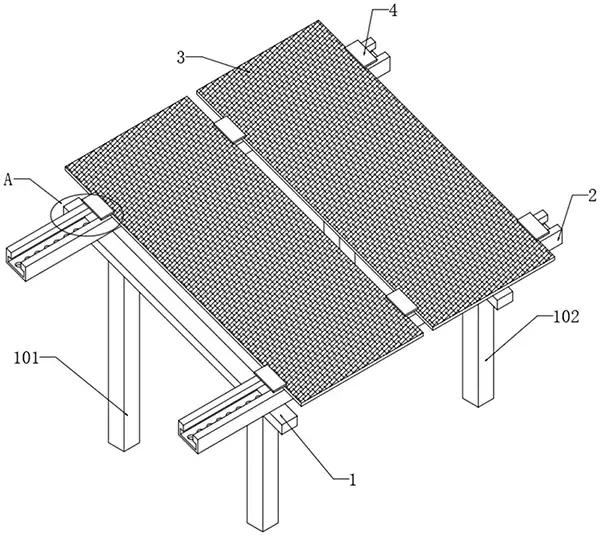

Énergie solaire

Nous avons établi de nombreux partenariats avec des entreprises du secteur de l'énergie solaire, en leur fournissant des composants de haute précision pour les panneaux solaires, les trackers et les systèmes de stockage d'énergie. Notre expertise en matériaux et procédés nous permet de fabriquer des pièces qui améliorent l'efficacité et la durabilité des technologies solaires.

Stockage d'énergie

Face à la demande croissante de solutions de stockage d'énergie, nous nous positionnons comme un partenaire de confiance pour les entreprises qui développent des technologies de batteries avancées. Nos capacités de prototypage rapide et de fabrication sur mesure nous permettent de fournir des composants adaptés aux exigences évolutives du marché du stockage d'énergie.

Énergie éolienne

Notre expérience s’étend à l’énergie éolienne, où nous livrons des composants de haute qualité pour les pales d’éoliennes, les nacelles et d’autres pièces essentielles.

En tirant parti de notre vaste expertise en matière de matériaux, de processus et de normes industrielles, nous fournissons des solutions innovantes qui favorisent la mise en œuvre réussie de projets d’énergie renouvelable.

- En tirant parti de notre vaste expertise en matière de matériaux, de processus et de normes industrielles, nous proposons des solutions innovantes qui favorisent la mise en œuvre réussie de projets d’énergie renouvelable.

Services et solutions

Les spécialistes automobiles Witcool proposent un usinage CNC de haute précision, offrant des solutions personnalisées qui favorisent l'innovation et garantissent d'excellentes performances dans la production de pièces.

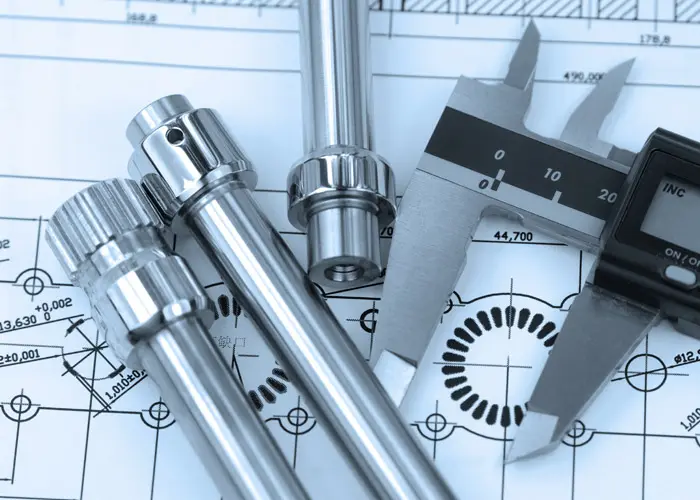

Usinage CNC

Création de structures précises et complexes par fraisage, tournage et post-traitement, parfaitement adaptées aux prototypes complexes et aux pièces métalliques fonctionnelles.

Coulée sous pression

Production rapide de pièces moulées et d'outillages intermédiaires, optimisés pour la production en série avec une qualité constante.

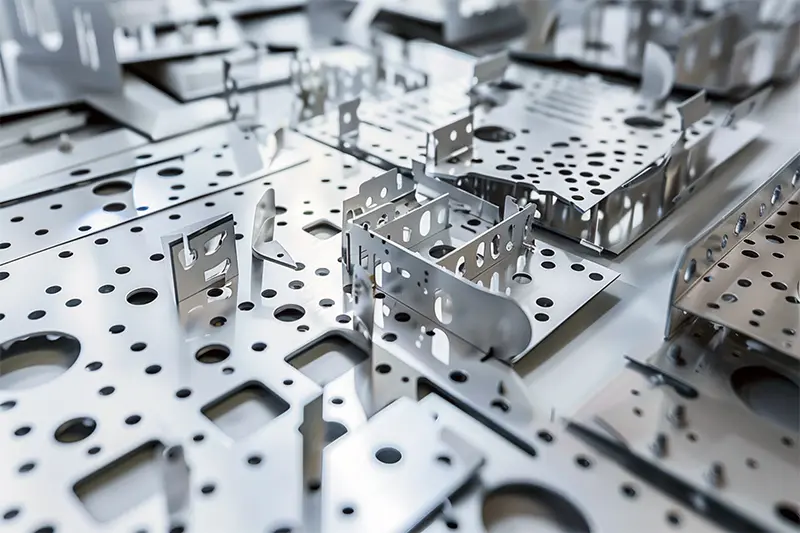

Traitement de la tôle

Offre une flexibilité dans la formation de composants métalliques précis pour diverses applications, garantissant à la fois adaptabilité et précision.

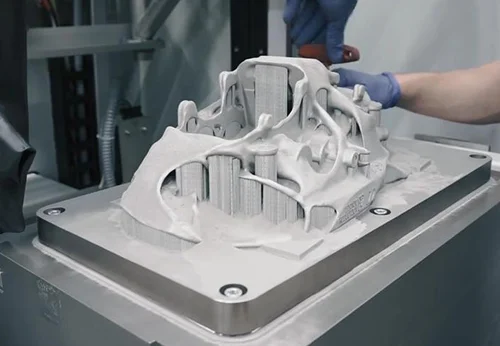

Impression 3D

Un processus rapide et polyvalent qui permet la création rapide de formes complexes à partir d'une variété de matériaux, idéal pour des conceptions innovantes.

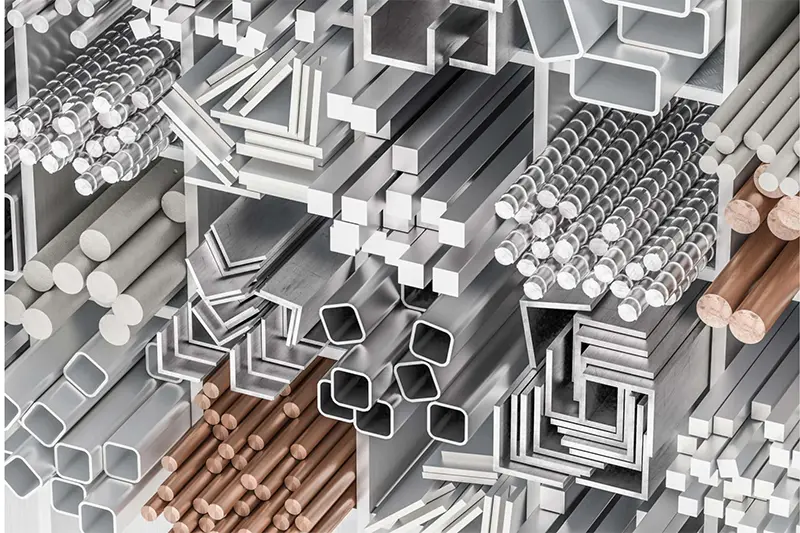

Matériaux et finitions de surface

Matériels

Nous proposons une large gamme de matériaux, notamment des métaux, des plastiques et des composites.

Finition de surface

Notre finition de haute qualité améliore la durabilité et l'apparence des pièces, répondant aux exigences des surfaces lisses et texturées.

Capacités de production énergétique

Notre engagement à fournir des services d’usinage CNC de haute qualité nous permet de produire des composants critiques qui répondent aux exigences des solutions énergétiques modernes.

« Witcool a dépassé nos attentes en termes de précision et de rapidité. Leur expertise et leur réactivité ont considérablement amélioré l'efficacité des systèmes solaires, réduit les délais et diminué les coûts. Nous recommandons vivement Witcool ! »

Améliorer les solutions solaires

Greencells devait améliorer les performances de son système solaire en fournissant des composants précis et en relevant les défis de la chaîne d'approvisionnement.

Usinage CNC de précision, technologies de fabrication avancées, optimisation des matériaux.

● Délais réduits de 30%

● Coûts des composants réduits de 15%

● Fiabilité accrue du système

« Witcool a démontré le plus haut niveau de précision et d'innovation, ce qui a conduit à des améliorations significatives de nos turbines. »

Fabrication de composants d'éoliennes

Witcool s'est associé à GE Renewable Energy pour produire des composants de précision destinés aux éoliennes. L'objectif était d'améliorer l'efficacité des éoliennes tout en minimisant les coûts de production.

Usinage CNC 5 axes, rectification de précision et prototypage.

● Coûts de production réduits de 20%

● Performances des composants améliorées grâce au 15%

Assurance qualité

Witcool garantit la plus haute précision et le respect de toutes les normes de qualité à chaque étape de la production. Nous suivons les normes internationales, notamment ISO et IATF, dans la création de composants fiables pour le secteur des nouvelles énergies. Des contrôles de qualité et des tests rigoureux garantissent que les produits répondent aux exigences strictes du secteur des nouvelles énergies et démontrent une fiabilité opérationnelle à long terme.

Usinage de précision et contrôle qualité

Dans le secteur des nouvelles énergies, l'usinage CNC est utilisé pour produire des composants clés tels que des boîtiers de batterie, des modules de gestion de l'alimentation et des pièces structurelles. Witcool applique un contrôle qualité strict à toutes les étapes, garantissant que chaque pièce est conforme aux exigences de tolérance les plus strictes. Nous avons mis en place un système complet de gestion de la qualité (TQM), où chaque étape de la production est surveillée en temps réel, minimisant les défauts et les erreurs. Nous utilisons des machines à mesurer tridimensionnelles (CMM) et des systèmes de mesure optique pour garantir la précision à chaque étape de la production.

processus de contrôle qualité :

Contrôle des matières premières :

Avant le début de la production, tous les matériaux sont soumis à des inspections rigoureuses pour garantir leur conformité aux normes de conception et aux normes de l’industrie.

Inspection en cours de fabrication :

À chaque étape critique de la production, des points de contrôle sont mis en œuvre pour éviter l’accumulation d’erreurs et assurer le respect des spécifications.

Inspection finale et vérification :

Une fois la production terminée, des contrôles approfondis des dimensions, de la qualité de surface et des tolérances sont effectués pour garantir le respect total des exigences techniques.

- Ces processus assurent une qualité maximale à chaque étape, garantissant la fiabilité du produit final.

Certification et normes de l'industrie

Nos processus de fabrication sont certifiés ISO 9001 et IATF 16949 (industrie des nouvelles énergies), ce qui confirme que tous les composants répondent aux normes internationales de qualité. Les matériaux et les processus sont strictement conformes aux exigences de l'industrie telles que RoHS et REACH, garantissant ainsi le respect des normes environnementales et de sécurité.

Normes relatives aux matériaux et aux procédés

Les composants du secteur des nouvelles énergies nécessitent une résistance élevée et une précision des matériaux. Witcool sélectionne des matériaux conformes aux normes industrielles, tels que les alliages d'aluminium, l'acier inoxydable et le titane, et applique des paramètres de traitement optimisés pour répondre pleinement aux exigences.

Test et vérification des produits

Witcool effectue des tests et des vérifications approfondis à chaque étape de la production, notamment des tests de fatigue, de résistance à la corrosion et de résistance aux chocs, qui sont particulièrement importants pour les pièces du secteur des nouvelles énergies. Ces tests confirment les excellentes performances et la fiabilité des pièces dans des conditions extrêmes.

Processus spécifiques de test et de vérification :

Essais de fatigue :

Simule la contrainte de charge sur les composants lors d'une utilisation prolongée pour éviter toute défaillance sous tension.

Essais de résistance à la corrosion :

Évalue la résistance des matériaux à la corrosion pour les pièces exposées à une humidité élevée ou à des environnements agressifs.

Essais d'impact :

Évalue la résistance et la durabilité des composants soumis à des impacts soudains ou à une pression élevée.

Vérification dimensionnelle :

Mesure la précision des pièces à l'aide de systèmes de mesure de haute précision pour garantir la conformité avec les tolérances au niveau du micron.

Système de suivi complet

Witcool utilise un système de suivi numérique qui enregistre chaque étape, des matières premières aux produits finis, ce qui permet de retracer les processus de production à tout moment. Cette approche assure une gestion transparente et permet de résoudre rapidement les problèmes potentiels de qualité.

Commentaires des clients et amélioration continue

Nous prenons en compte les retours de nos clients du secteur des nouvelles énergies et améliorons en permanence nos technologies CNC. En optimisant les processus et en mettant en œuvre les méthodes d'usinage les plus récentes, Witcool garantit la livraison de composants répondant aux normes de qualité les plus élevées.

Questions fréquemment posées

Witcool possède une vaste expérience dans l'usinage CNC et est prêt à offrir des solutions de haute précision pour le secteur de l'énergie, garantissant qualité, fiabilité et innovation dans chaque projet.

Quelle est l’application de la CNC dans la fabrication de composants pour les nouvelles énergies ?

La CNC est utilisée pour produire des composants de haute précision tels que des pales d'éoliennes et des pièces de panneaux solaires, garantissant la fiabilité et la durabilité de ces systèmes.

Quels matériaux sont utilisés dans l’usinage CNC pour les nouvelles énergies ?

Nous utilisons des alliages, des composites et d’autres matériaux spécialisés qui répondent aux exigences de l’industrie et offrent des performances élevées.

Quelles normes de qualité sont respectées lors de la production de composants pour l’énergie ?

Nous sommes certifiés ISO 9001 et ISO 14001, confirmant le respect des normes internationales de qualité et d'environnement.

Comment la CNC contribue-t-elle à réduire les coûts de production des projets énergétiques ?

La haute précision de la CNC réduit les défauts et optimise l’utilisation des matériaux, réduisant ainsi les coûts globaux.

Quels types de composants énergétiques peuvent être fabriqués à l’aide de la CNC ?

Nous fabriquons des pièces pour panneaux solaires, des batteries, ainsi que des composants pour éoliennes et installations énergétiques.

Quel rôle joue la CNC dans le soutien des technologies respectueuses de l’environnement ?

La CNC contribue à créer des composants pour les sources d’énergie renouvelables, soutenant ainsi une production respectueuse de l’environnement.