Le choix de la technique de fraisage adaptée, qu'il s'agisse de fraisage à 3, 4 ou 5 axes, peut avoir un impact considérable sur l'efficacité et la qualité de vos processus de fabrication. Ce guide vous aidera à comprendre les principales différences et avantages de chaque type, vous permettant ainsi de faire le meilleur choix en fonction de vos besoins de production.

Qu'est-ce que le fraisage CNC ?

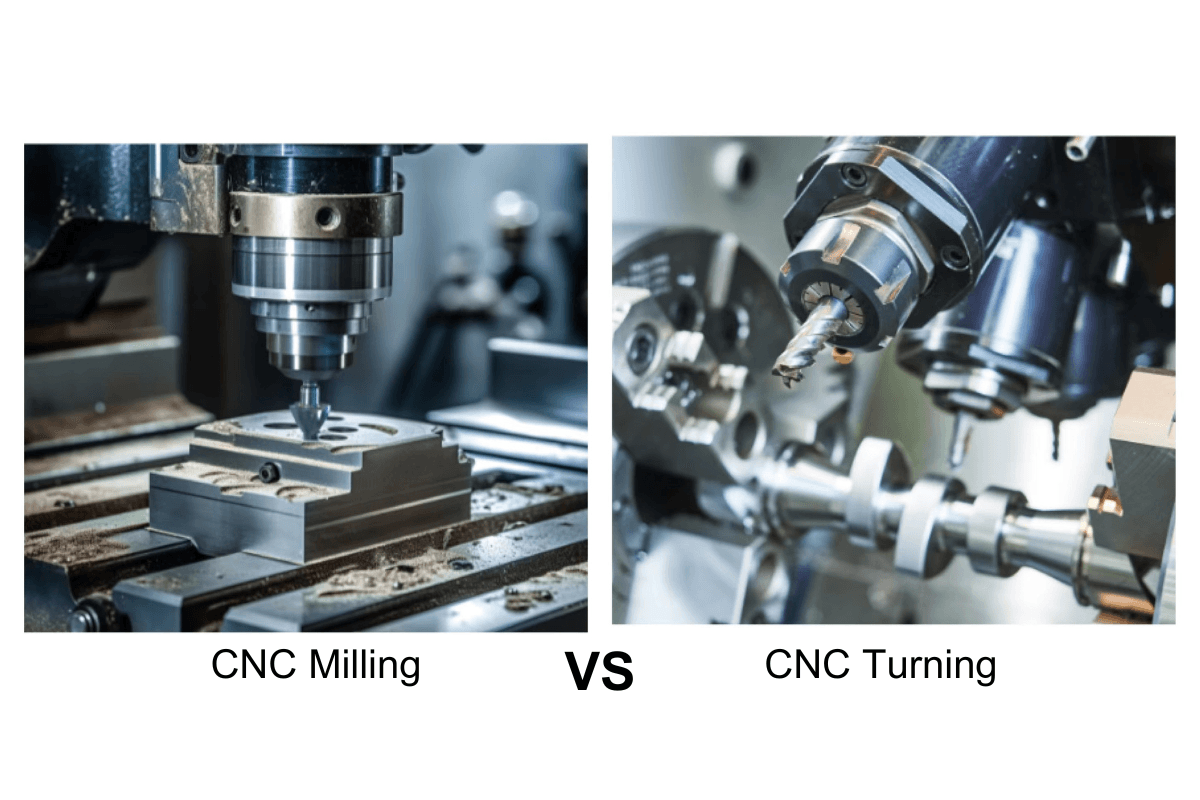

Fraisage CNC Il s'agit d'un procédé d'usinage utilisé dans la fabrication qui implique l'enlèvement de matière d'une pièce à l'aide de fraises rotatives contrôlées par ordinateur. CNC signifie « Computer Numerical Control » (Contrôle numérique par ordinateur), ce qui signifie que la fraiseuse est commandée par un logiciel informatique préprogrammé, ce qui permet une grande précision et une répétabilité.

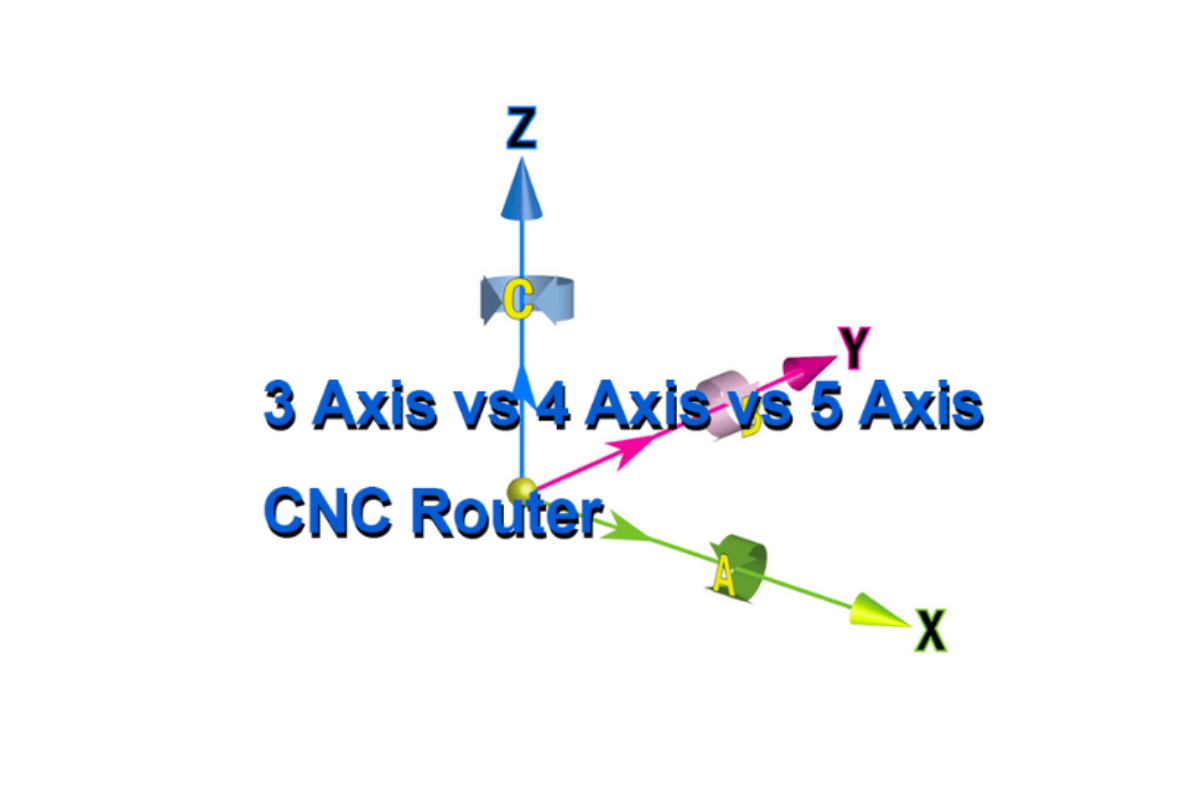

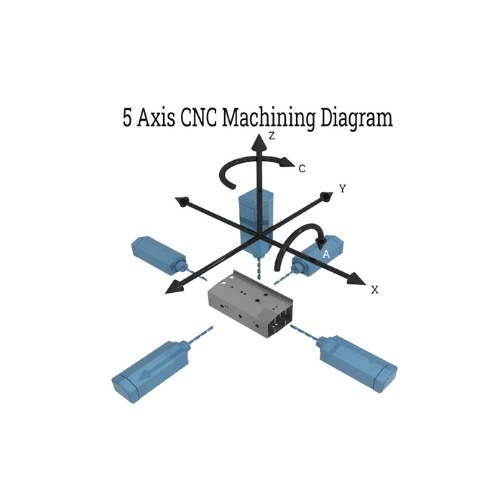

Dans le domaine du fraisage CNC, l'« axe » désigne le nombre de directions dans lesquelles l'outil de coupe peut se déplacer. Un plus grand nombre d'axes permet généralement des opérations de coupe plus complexes et plus précises.

Fraisage CNC à 3 axes

Les machines CNC à 3 axes sont le type d'équipement CNC le plus courant. Elles fonctionnent selon trois axes principaux : X, Y et Z.

- Axe X : Se déplace horizontalement.

- Axe Y : Se déplace verticalement.

- Axe Z : Se déplace de haut en bas.

Applications :

Les machines à 3 axes sont idéales pour les pièces simples et plates qui ne nécessitent pas de caractéristiques complexes ou de faces multiples. Elles sont couramment utilisées pour le perçage, le fraisage et la découpe de surfaces planes. En raison de leur simplicité, elles sont rentables et idéales pour la production en grande série de pièces simples.

Limites:

La limitation de l'usinage 3 axes est son incapacité à créer efficacement des pièces aux géométries complexes. Lorsque des éléments complexes sur plusieurs côtés d'une pièce sont nécessaires, des configurations ou des processus d'usinage supplémentaires sont nécessaires, ce qui peut augmenter le temps et les coûts de production.

Fraisage CNC à 4 axes

Les machines CNC à 4 axes fonctionnent sur les mêmes trois axes qu'une machine à 3 axes, mais avec un axe de rotation supplémentaire, généralement appelé axe A.

- Axe A : Rotation autour de l'axe X.

Avantages :

L'usinage 4 axes augmente l'efficacité en réduisant le nombre de réglages nécessaires. Il améliore également la précision du produit final puisque la pièce reste fixée en place pendant le processus d'usinage.

Applications :

L'ajout de l'axe A permet à la machine de faire tourner la pièce, ce qui permet d'usiner plusieurs côtés sans repositionner la pièce manuellement. Cela est particulièrement utile pour usiner des éléments tels que des trous ou des fentes sur les côtés d'une pièce. Il est couramment utilisé dans les opérations qui nécessitent une grande précision et la possibilité de travailler sur différents côtés d'une pièce sans configurations supplémentaires.

Fraisage CNC 5 axes

Les machines CNC à 5 axes sont les plus avancées, offrant le plus haut niveau de précision et de polyvalence. En plus des axes X, Y, Z et A, les machines à 5 axes ajoutent un cinquième axe de rotation, souvent appelé axe B.

- Axe B : Rotation autour de l'axe Y.

Voici quelques-uns des principaux avantages de l'usinage 5 axes :

- Capacité d'usiner des pièces complexes à plusieurs faces dans une seule configuration

- Finition de surface améliorée et tolérances plus strictes

- Temps de configuration réduit et efficacité accrue

- Capacité d'usiner des contre-dépouilles et des zones difficiles d'accès

Applications :

L'usinage 5 axes est essentiel pour créer des pièces complexes et élaborées qui nécessitent un usinage sur plusieurs faces avec des tolérances très strictes. Des secteurs tels que l'aérospatiale, l'automobile et la fabrication de dispositifs médicaux s'appuient fortement sur l'usinage 5 axes pour produire des pièces aux géométries complexes.

Choisir l'usinage CNC adapté à vos besoins

Lorsque vous choisissez entre l'usinage CNC à 3, 4 et 5 axes, il est essentiel de prendre en compte la complexité des pièces que vous devez produire, la précision requise et votre volume de production.

- 3 axes : Idéal pour les pièces simples et la production en grande série.

- 4 axes : Idéal pour les pièces plus complexes qui nécessitent un usinage sur plusieurs côtés avec une plus grande précision.

- 5 axes : Nécessaire pour les pièces les plus complexes avec des géométries complexes et des tolérances serrées.

Conclusion

En conclusion, il est essentiel de comprendre les différences entre le fraisage 3 axes, 4 axes et 5 axes pour optimiser vos opérations de fabrication. Alors que l'usinage 3 axes est une option rentable pour les pièces simples, l'usinage 4 axes et 5 axes offre des niveaux croissants de complexité, de précision et d'efficacité pour les besoins de fabrication plus avancés. Le choix entre ces options dépendra des exigences spécifiques de vos pièces et de vos objectifs de fabrication globaux.

Si vous avez des questions ou si vous avez besoin d'aide pour sélectionner les services d'usinage CNC adaptés à votre entreprise, n'hésitez pas à contacter notre équipe chez Witcool Machinery. Nous sommes spécialisés dans la fourniture de solutions CNC personnalisées adaptées aux exigences uniques de diverses industries. Visitez notre site Web à l'adresse www.witcoolmachining.com pour en savoir plus.

FAQ

Q : Quelles sont les principales différences entre l’usinage CNC à 3, 4 et 5 axes ?

R : Les principales différences résident dans le nombre d'axes le long desquels l'outil de coupe peut se déplacer. Une machine à 3 axes déplace l'outil le long de trois axes (X, Y, Z), tandis qu'une machine à 4 axes ajoute un axe de rotation (axe A) pour permettre l'usinage sur plusieurs côtés sans repositionnement manuel. Une machine à 5 axes ajoute un cinquième axe (axe B) pour encore plus de flexibilité, permettant d'usiner des géométries complexes et des pièces complexes en une seule configuration.

Q : Quel type de machine CNC dois-je choisir pour mon projet ?

R : Le choix dépend de la complexité et de la précision requises pour vos pièces. Une machine à 3 axes convient aux pièces simples et plates, tandis qu'une machine à 4 axes est plus adaptée aux pièces présentant des caractéristiques sur plusieurs côtés. Si votre projet implique des géométries très complexes ou nécessite un usinage sur plusieurs surfaces avec des tolérances serrées, une machine à 5 axes est la meilleure option.

Q : Comment l’usinage CNC 5 axes améliore-t-il l’efficacité de fabrication ?

R : L'usinage CNC à 5 axes améliore l'efficacité en permettant l'usinage de pièces complexes en une seule configuration, réduisant ainsi le besoin de configurations multiples et de repositionnement. Cela permet non seulement de gagner du temps, mais aussi d'améliorer la précision et la qualité du produit final, car la pièce reste fixée en place pendant l'usinage.

Q : Quelles industries bénéficient le plus de l’usinage CNC 5 axes ?

R : Les industries qui nécessitent des pièces extrêmement complexes et précises sont celles qui bénéficient le plus de l'usinage CNC 5 axes. Il s'agit notamment de l'aéronautique, de l'automobile, de la fabrication d'appareils médicaux et des industries de fabrication de moules complexes, où des géométries complexes et des tolérances strictes sont essentielles.

Q : L’usinage CNC 4 axes est-il un bon compromis entre coût et capacité ?

R : Oui, l'usinage CNC 4 axes offre un bon équilibre entre coût et capacité. Il permet d'usiner des pièces plus complexes par rapport aux machines 3 axes tout en étant moins coûteux que les machines 5 axes. Il est idéal pour les projets qui nécessitent un usinage sur plusieurs côtés mais qui ne nécessitent pas toute la complexité de l'usinage 5 axes.

Q : Les machines CNC à 3 axes peuvent-elles traiter des pièces complexes ?

R : Bien que les machines CNC à 3 axes soient principalement adaptées aux pièces plus simples, elles peuvent néanmoins gérer un certain niveau de complexité grâce à plusieurs configurations ou à l'utilisation de dispositifs spécialisés. Cependant, pour les pièces aux géométries complexes ou nécessitant un usinage sur plusieurs faces, les machines à 4 ou 5 axes sont plus efficaces et plus précises.