Introducción

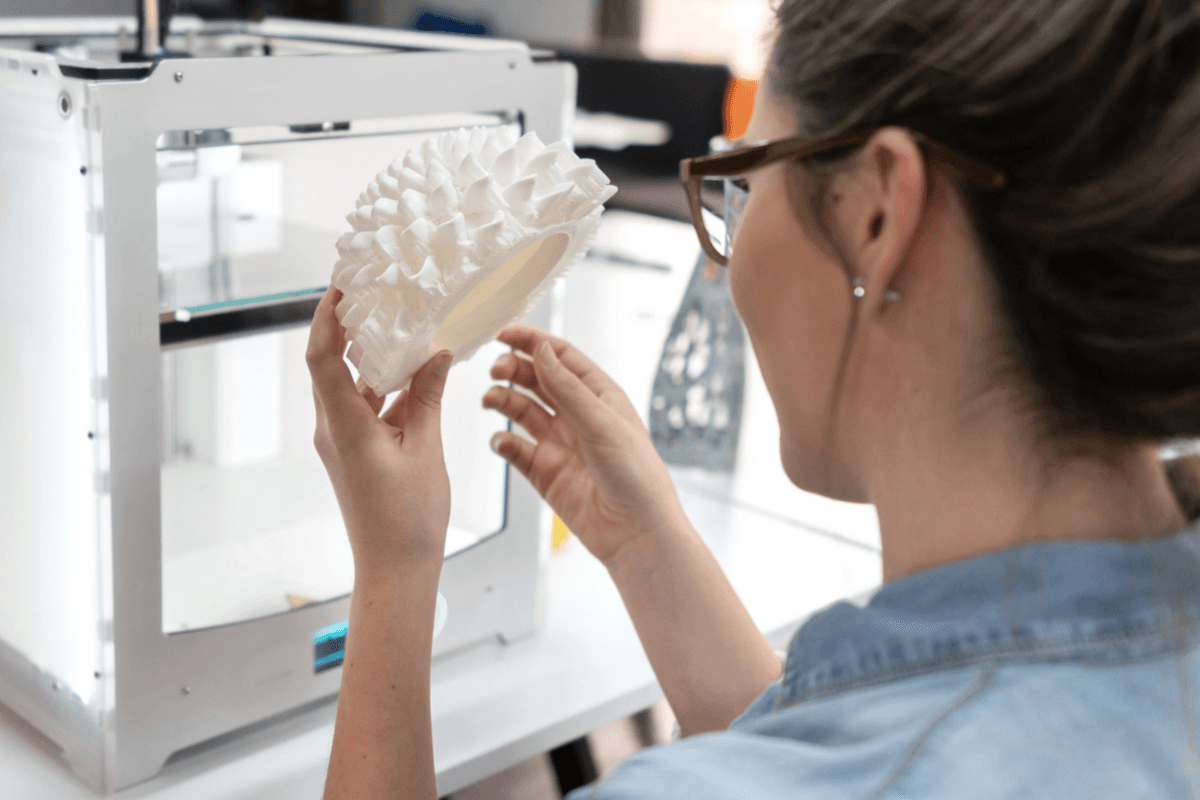

Impresión 3D En la industria médica está revolucionando la producción de componentes personalizados de alta calidad. Cuando un importante fabricante de dispositivos médicos necesitaba una abrazadera personalizada para un nuevo dispositivo de diagnóstico, recurrió a nuestras avanzadas capacidades de impresión 3D. El objetivo era crear una abrazadera resistente y ligera con dimensiones precisas, fundamentales para su rendimiento en un entorno médico.

Desafío

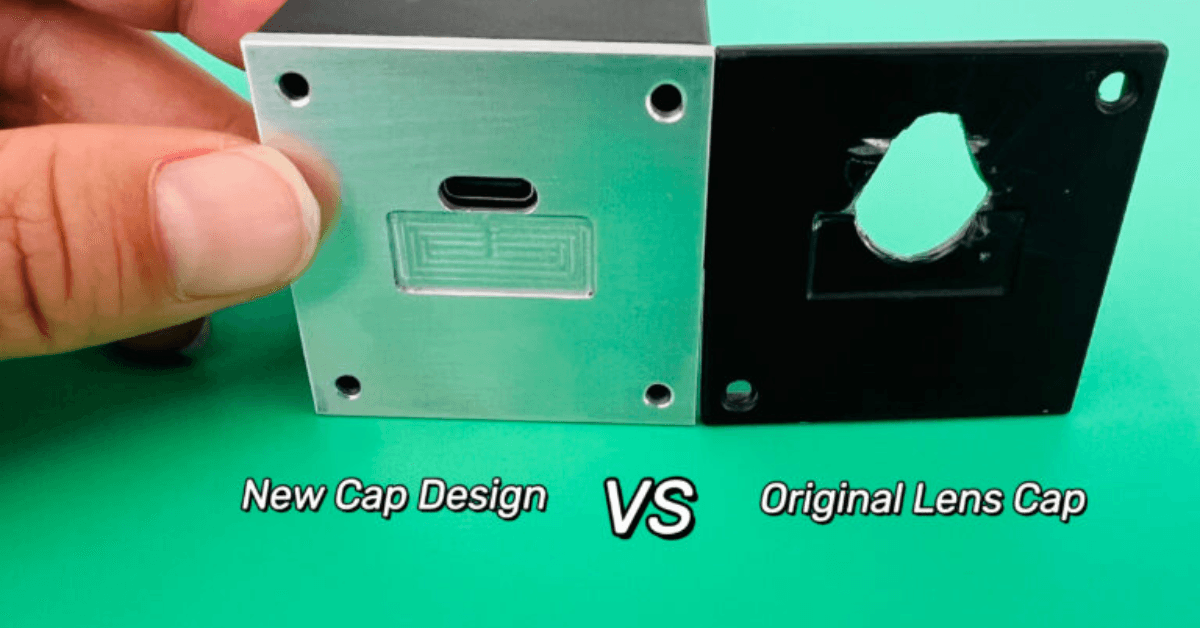

El principal desafío era crear una abrazadera que pudiera fabricarse de forma rápida y económica sin comprometer la calidad ni la precisión necesarias para las aplicaciones médicas. Los métodos de fabricación tradicionales, como el moldeo por inyección, habrían sido demasiado costosos y demandaban demasiado tiempo para la fase inicial de creación de prototipos.

Solución

Aprovechamos nuestras avanzadas capacidades de impresión 3D para producir la abrazadera utilizando material ABS blanco, conocido por sus excelentes propiedades mecánicas y facilidad de uso en la creación de prototipos. Elegimos el ABS por su robustez, que es esencial para garantizar la durabilidad y la fiabilidad de la abrazadera en un entorno médico.

Proceso

- Optimización del diseño: Nuestro equipo de ingeniería trabajó en estrecha colaboración con el cliente para perfeccionar el diseño de la abrazadera, garantizando que cumpliera con todos los requisitos funcionales y pudiera fabricarse fácilmente utilizando tecnología de impresión 3D.

- Impresión 3D: Con nuestras impresoras 3D de alta precisión, hemos producido la abrazadera con un nivel de detalle impecable. El uso de material ABS permitió obtener un componente resistente y duradero, adecuado para aplicaciones médicas.

- Seguro de calidad: Cada pinza impresa se sometió a rigurosos controles de calidad para garantizar que cumpliera con las especificaciones y estándares requeridos para uso médico. Esto incluyó precisión dimensional, pruebas de resistencia e inspecciones visuales.

Resultado

El uso de la tecnología de impresión 3D nos permitió entregar un prototipo funcional y de alta calidad de la pinza médica en un plazo de tiempo significativamente menor en comparación con los métodos de fabricación tradicionales. El cliente pudo avanzar rápidamente con las pruebas y la validación de su nuevo dispositivo médico, acelerando en última instancia su ciclo de desarrollo del producto.

Beneficios

- Prototipado rápido: Plazo de entrega significativamente reducido, lo que permite un desarrollo más rápido del producto.

- Rentable: Costes de producción más bajos para el prototipado inicial en comparación con los métodos tradicionales.

- Alta precisión: Componentes precisos y confiables que cumplen con los estrictos requisitos de la industria médica.

- Personalización: Modifique y optimice fácilmente los diseños según los comentarios de las pruebas.

Conclusión

El éxito de este proyecto demostró cómo la impresión 3D puede agilizar la creación de prototipos, reducir significativamente los plazos de entrega y disminuir los costos en comparación con los métodos de fabricación tradicionales. Al aprovechar la impresión 3D, los fabricantes de dispositivos médicos pueden iterar rápidamente los diseños, probar prototipos y lanzar productos innovadores al mercado con mayor rapidez. Este enfoque permite una mayor personalización y adaptabilidad, lo que garantiza que incluso los componentes más complejos cumplan con los estrictos requisitos de la industria médica.

Además, la impresión 3D permite la producción a demanda, minimiza los residuos y promueve el uso eficiente de los materiales, lo que es crucial para la precisión y la sostenibilidad. A medida que la tecnología evolucione, es probable que su papel en el campo médico se amplíe, impulsando una mayor innovación y mejorando los resultados para los pacientes.

Próximos pasos

¿Interesado en aprender más sobre cómo nuestro Servicios de impresión 3D ¿Qué puede beneficiar a sus proyectos de dispositivos médicos? Contáctenos hoy para comenzar su proyecto y ver la diferencia que puede generar la tecnología de fabricación avanzada.

Preguntas frecuentes

P1: ¿Qué materiales se utilizan para las abrazaderas médicas impresas en 3D?

A1: Nosotros Utilizamos principalmente plástico ABS blanco para abrazaderas médicas impresas en 3D, elegido por su resistencia, durabilidad y biocompatibilidad, lo que lo hace ideal para aplicaciones médicas.

P2: ¿Qué precisión tienen las abrazaderas impresas en 3D para dispositivos médicos?

A2: Nuestro Las abrazaderas impresas en 3D son altamente precisas, con tolerancias típicamente de ±0,1 mm, lo que garantiza un rendimiento confiable en el ensamblaje de dispositivos médicos.

P3: ¿Se pueden personalizar las abrazaderas impresas en 3D para dispositivos médicos específicos?

A3: Sí, nuestras abrazaderas impresas en 3D se pueden personalizar completamente para satisfacer los requisitos específicos de sus dispositivos médicos, diseñados en estrecha colaboración con los clientes.

P4: ¿Cuáles son los beneficios de utilizar abrazaderas impresas en 3D en el ensamblaje de dispositivos médicos?

A4: Las abrazaderas impresas en 3D ofrecen creación rápida de prototipos, rentabilidad, alta precisión y la capacidad de crear geometrías complejas, acelerando el proceso de desarrollo.

P5: ¿Cuánto tiempo se tarda en producir una abrazadera impresa en 3D para uso médico?

A5: El tiempo de producción varía según la complejidad y la cantidad, pero los prototipos normalmente se entregan en unos pocos días, lo que permite iteraciones y pruebas rápidas.