China Custom

CNC Machining Services

Witcool, a 17-year-old CNC machining factory in China, leverages the country’s robust industrial chain to provide custom machined parts at low cost.

- No MOQ, From 1PC To 5000+ PCS

- ISO 9001: 2015 Certificated

- Lead Times As Short As 1 Day

- Tolerance As Tight As ± 0.005 mm

- Providing Customized Designs and Manufacturing Solutions

- *All uploads are secure and confidential.

*If you have any design files that need to be sent, please email them to [email protected]

Trusted by

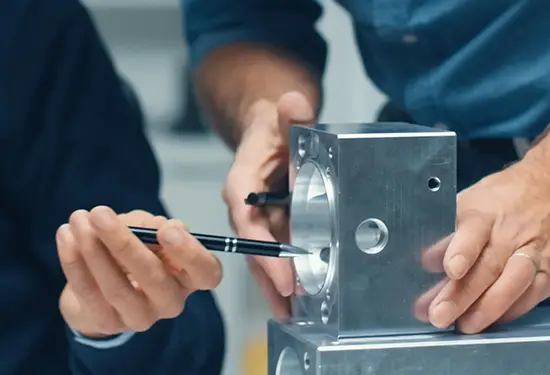

Our CNC Machining Services

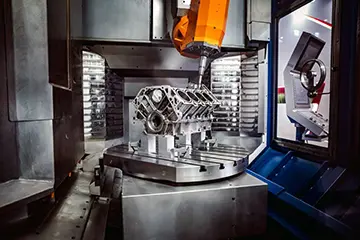

5 axis CNC Machining

We use advanced multi-axis CNC machines, including 5-axis centers, to produce highly precise parts with simple or complex geometries.

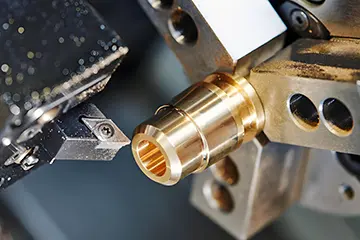

CNC Milling

On-demand CNC milling for rapid prototypes and production parts. Custom milled from high-quality metals and plastics with a 0.01 mm tolerance. Parts ready in as fast as 1 day.

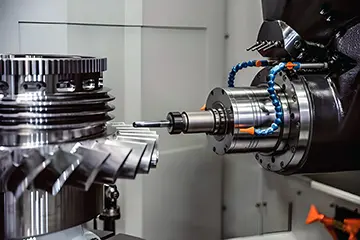

CNC Turning

Our CNC turning center produces custom parts with a 0.02 mm tolerance in as fast as 1 day, offering fast lead times and competitive pricing for prototyping and production.

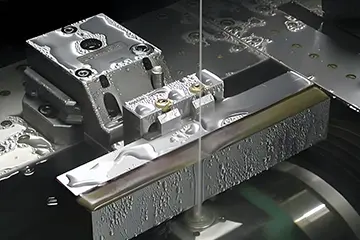

Wire EDM Machining

Witcool provides premier wire EDM services, supplying high-precision prototypes, low- to high-volume runs, and long-term EDM component production across various industries.

Don’t just take our word for it – feel the quality of our work in your hands.

Click the button below to request your CNC part sample today and discover why businesses across various industries trust us for their CNC machining needs.

Gallery of CNC Machined Parts

Explore our portfolio of custom-manufactured parts for clients, precision-machined from metals and plastics. Sizes span from 0.078” (2mm) to 118” (3,000mm), with diverse surface finishes and advanced machining capabilities. No matter your requirements, we deliver high-quality components engineered to your exact specifications.

Materials and Surface Treatment

Our ability to handle a wide range of materials for CNC machining is rooted in our extensive experience, advanced machinery, and skilled team.

Metals

- Alumminum

- Tool Steel

- Stainless Steel

- Brass

- Copper

- Titanium

- Tungsten Steel

- Alumina Ceramics

- and more

Plastics

- POM

- MC Nylon

- PVC

- PEEK

- PA6

- Delrin

- UHMW

- Glass Fiber

- and more

Surface Treatment

- Heat Treatment

- Sand Blasting

- Brushing

- Polishing

- Hard Chrome

- Black Oxide

- Nickle Plated

- Nickle Plated

- and more

Tolerances in CNC Machining

Witcool utilizes advanced CNC machines to ensure high precision in machining parts. We offer tolerances of up to ±0.005 mm, allowing us to produce components with minimal deviation and exceptional accuracy.

| Icon | Standards | Tolerance | Icon | Standards | Tolerance | |

|---|---|---|---|---|---|---|

| Common Tolerance | 0.0004" (±10μm / ±0.01мм) | Diameter Tolerance | 0.00004" (±1μm / ±0.001мм) | |||

| Flatness | 0.00004" (2μm / 0.002мм) | Straightness | 0.00004" (1μm / 0.001мм) | |||

| Perpendicularity | 0.0002" (5μм / 0.005мм) | Parallelism | 0.0001" (2.5μм / 0.0025мм) | |||

| Roundness | 0.0002" (5μм / 0.005мм) | Concentricity | 0.00002" (0.5μм / 0.0005мм) | |||

| Cylindricity | 0.0002" (5μм / 0.005мм) | Symmetry | 0.0003" (8μм / 0.008мм) | |||

|

|

Circular Runout | 0.00004" (1μм / 0.001мм) | Positional Tolerance | 0.005mm |

Don’t just take our word for it – feel the quality of our work in your hands.

Click the button below to request your CNC part sample today and discover why businesses across various industries trust us for their CNC machining needs.

Our Factory

At Witcool, flexibility and efficiency are the cornerstones of our operations. Whether you require rapid prototypes or large-scale production, our highly skilled team and state-of-the-art facilities seamlessly adapt to meet your needs. We prioritize the utmost confidentiality in handling your designs and projects, safeguarding your trust throughout every stage of collaboration.

why choose us

IP Asset Security

Your intellectual property is protected through enforceable NDAs and secure protocols (encrypted transfers, access controls) during all project phases.

Transparent Production

You will have full visibility into every stage of the project. We ensure a transparent and well-controlled production process, keeping you informed from start to finish.

Fast Delivery Capability

Lean manufacturing workflows enable rapid turnaround: small batches ship within 4 days, and large-scale orders are delivered on schedule. Expedited production slots are reserved for urgent requests.

Flexible Payment

Flexible payment terms are available, including FOB, DAP, TT, L/C, and milestone-based phased payments, designed to optimize your cash flow management.

Quick Response

Our 24/7 after-sales team is on standby to resolve technical issues promptly. Lifetime support includes free repairs, replacements, and design optimizations for sustained performance.

quality control

1-Incoming Material Inspection

Inspect raw materials for appearance, dimensions, composition, and hardness compliance. Document test data for traceability.

2-In-process Inspection

Perform real-time dimensional and visual checks after each production step. Record data to ensure specification adherence.

3-First Article Inspection(FAI)

Validate the first completed unit against design drawings. Generate an FAI report documenting critical dimensions.

4-Final Product Inspection

Test finished products for appearance, dimensions, performance, and functionality. Issue a QA report certifying compliance with customer specs.

Don’t just take our word for it – feel the quality of our work in your hands.

Click the button below to request your CNC part sample today and discover why businesses across various industries trust us for their CNC machining needs.

Industries We Serve

Witcool is a professional manufacturer of CNC machined components. We manufacture precision metal parts that are generally used in different categories of industries including:

Automotive

Robotics

Energy

Medical Equipment

Optical Lens

Aerospace

Don’t just take our word for it – feel the quality of our work in your hands.

Click the button below to request your CNC part sample today and discover why businesses across various industries trust us for their CNC machining needs.

TESTIMONIALS

What Our Clients Say

including the United States, United Kingdom, Canada, Germany, Switzerland and Australia.

Production Manager

FAQs of The Custom CNC Machining

Below you can find some frequently asked questions about purchasing cnc parts. Please feel free to contact us if you have any other questions.

Q: Can you manufacture precision machined parts?

A: Yes! We specialize in high-precision machining, offering tolerance accuracy up to ±0.01mm, along with stringent tolerance requirements for form, position, surface roughness, curvature, and other complex specifications.

Q: Do you accommodate small batch orders?

A: Absolutely. We accept orders of any size, from single prototypes to 10-unit small batches or thousands for mass production. For small orders, we provide rapid turnaround services to accelerate design validation and project timelines..

Q: Does WITCOOL have the capability for complex parts?

Q: What materials do you work with?

A: We machine a wide range of materials: aluminum (6061, 7075), stainless steel (304, 316), titanium alloys, copper, and engineering plastics (POM, ABS, PC). For specialized requests like high-hardness alloys or custom materials, our procurement team offers tailored solutions compliant with international standards (RoHS, REACH).

Q: How responsive is WITCOOL’s customer service?

A: Our customer service team ensures seamless communication. Whether via email, phone, or online chat, we respond within 1 hour on weekdays. Engineers provide real-time updates during production and adapt workflows as needed to meet your goals.

Q: What is your typical lead time?

A: Standard orders ship in 7–10 days, while urgent requests can be expedited to 3–5 days. We optimize production schedules to meet tight deadlines without compromising quality. Contact us for customized delivery plans.

Q: Can you share industry experience or case studies?

A: With 17+ years in machining expertise, we serve the aerospace, automotive, medical, electronics, and industrial sectors, having delivered over 500,000 precision parts to 6,400+ global clients, including industry leaders such as Toyota, Tesla, and Emerson. Upon request, we can share industry-specific case studies or project references tailored to your needs.

Q: What post-delivery support do you offer?

A: Our after-sales team provides prompt technical assistance. If issues arise (e.g., dimensional errors, surface defects), we investigate immediately and resolve via repairs, reprocessing, or part optimization—ensuring your satisfaction throughout the product lifecycle.

Ask For A Quick Quote

Get instant pricing, project lead times,

and DFM feedback.

- *All uploads are secure and confidential.

*If you have any design files that need to be sent, please email them to [email protected]

Join 6,400+ Companies Who Use Witcool For High Quality Parts

Contact Witcool Team for a quick quote.

- +86-13412350358

- Building 2, No. 6 Shangxin Road, Xin'an Community, Chang'an Town, Dongguan City 523880, Guangdong Province, China

Pre-Inquiry Checklist:

- Quantity

- Material

- Heat Treatment (if necessary)

- Surface Finish (if necessary)

3D CAD files in STEP, IGS, or DWG format; 2D files in PDF format.

PDF drawings should include tolerances, critical dimensions and threaded holes.