CNC Turning Services

Our CNC turning service offers precise, efficient machining for various components. Using advanced equipment, we produce accurate parts tailored to your specifications. Perfect for creating cylindrical parts, our service handles both small and large production runs. Trust us for reliable, high-quality CNC turning solutions to meet your needs.

- Precision Turning Capabilities

- High Precision and Accuracy

- Short-Run Production Flexibility

- Excellent Surface Finish

Trust by

Manufacturing on Demand

Get instant pricing, project lead times,

and DFM feedback.

- *All uploads are secure and confidential.

*If you have any design files that need to be sent, please email them to [email protected]

Professional Team

Our professional team ensures precise CNC turning, delivering high-quality components to meet your exact specifications.

Top Quality

Our CNC turning service guarantees top quality, delivering precise and reliable machining for your components.

Fast Delivery

Our CNC turning service ensures fast delivery, providing precise and reliable parts quickly to meet your needs.

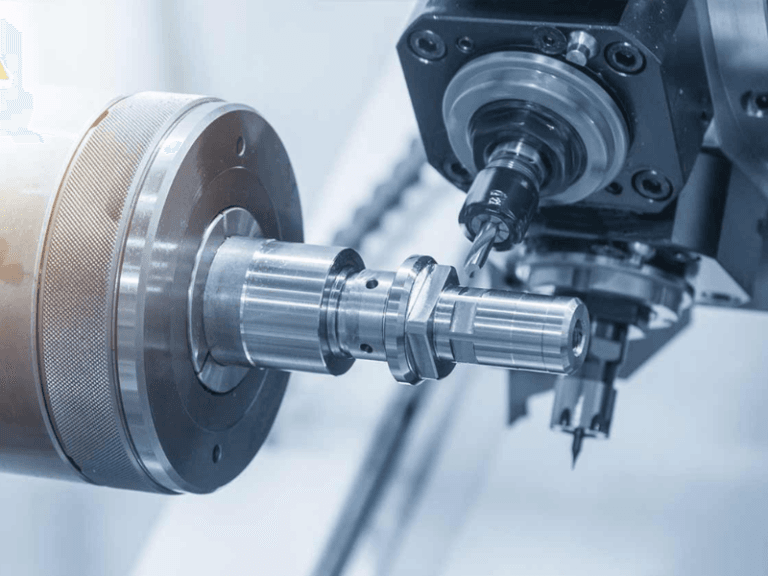

What is CNC Turning

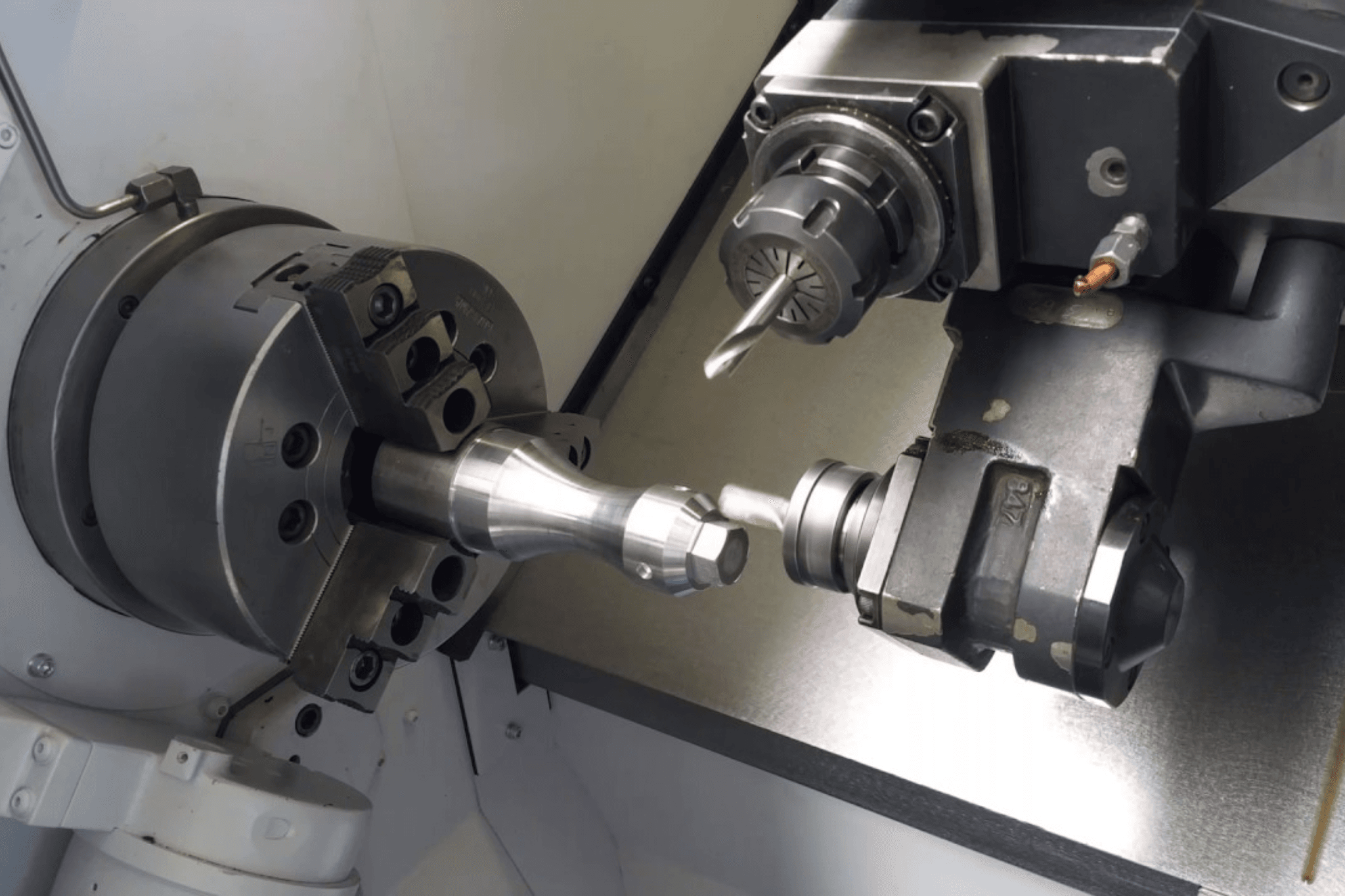

The Basics of CNC Lathes:

Turning activities can be conducted with the support of computer-controlled sequentially controlled lathes. There are a variety of key components that collectively make a milling machine. The headstock is responsible for holding the spindles and chuck, which grasp the workpiece. The work surface provides a sturdy platform, and its carriage drives the cutting tool. If necessary, the tailstock also supports the opposite end of the workpiece. CNC lathes are crucial for generating high-quality cylindrical components because they follow programmed instructions, which enable accurate and repeatable operations.

How CNC Turning Works:

The workpiece is clamped into the lathe’s chuck and turned at high speeds in CNC turning. To achieve the required dimensions, a stationary cutting tool is spun radially and along the workpiece’s axis to remove material. A computer software called G-code controls the whole operation by dictating the cutting tool’s speed, depth, and movement. Producing complex shapes and features with tight tolerances is now possible because to this automation’s great precision and consistency.

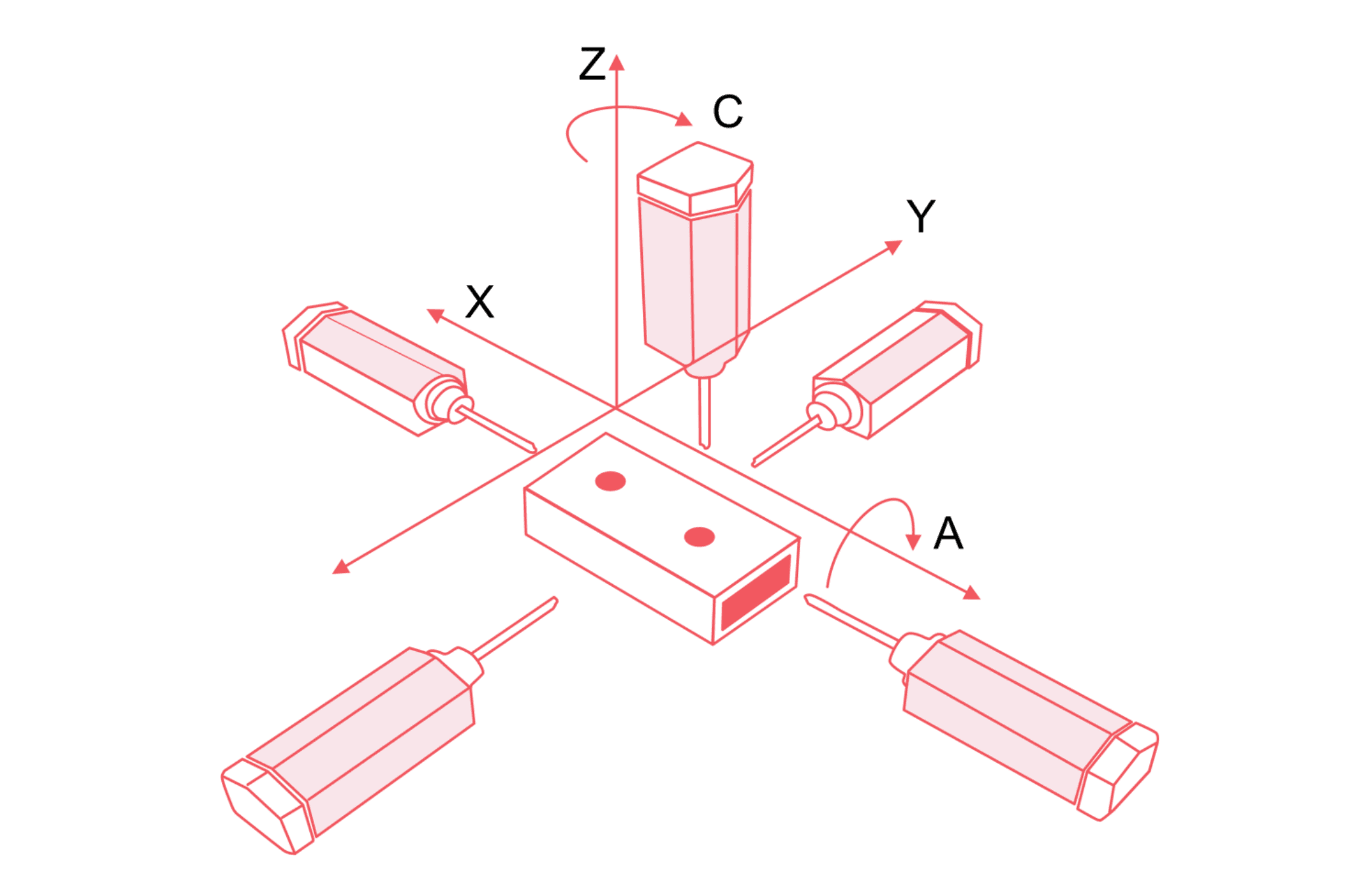

Types of CNC Lathes:

Horizontal and vertical CNC lathes are the two most common varieties. For turning a variety of pieces, from the most basic to the most intricate, the most typical CNC lathes are horizontal in design. Adaptable to a wide range of manufacturing requirements, they are very adaptable. Conversely, bigger and heavier workpieces are better suited for vertical CNC lathes. Ideal for large-scale industrial applications, their vertical position facilitates loading and unloading of heavy components and enhances stability during machining.

Benefits of CNC Turning:

The extreme accuracy and repeatability offered by CNC turning are only two of the many advantages that make this process ideal for producing high-quality parts in bulk. Production time and expenses are both cut down by the process’s extreme efficiency. CNC turning is versatile because it can process intricate shapes and features to exacting standards. Also, it lessens the need for physical work, which means less room for human mistake and more output overall. All the way from prototypes to mass production, CNC turning is a vital part of contemporary manufacturing due to these benefits.

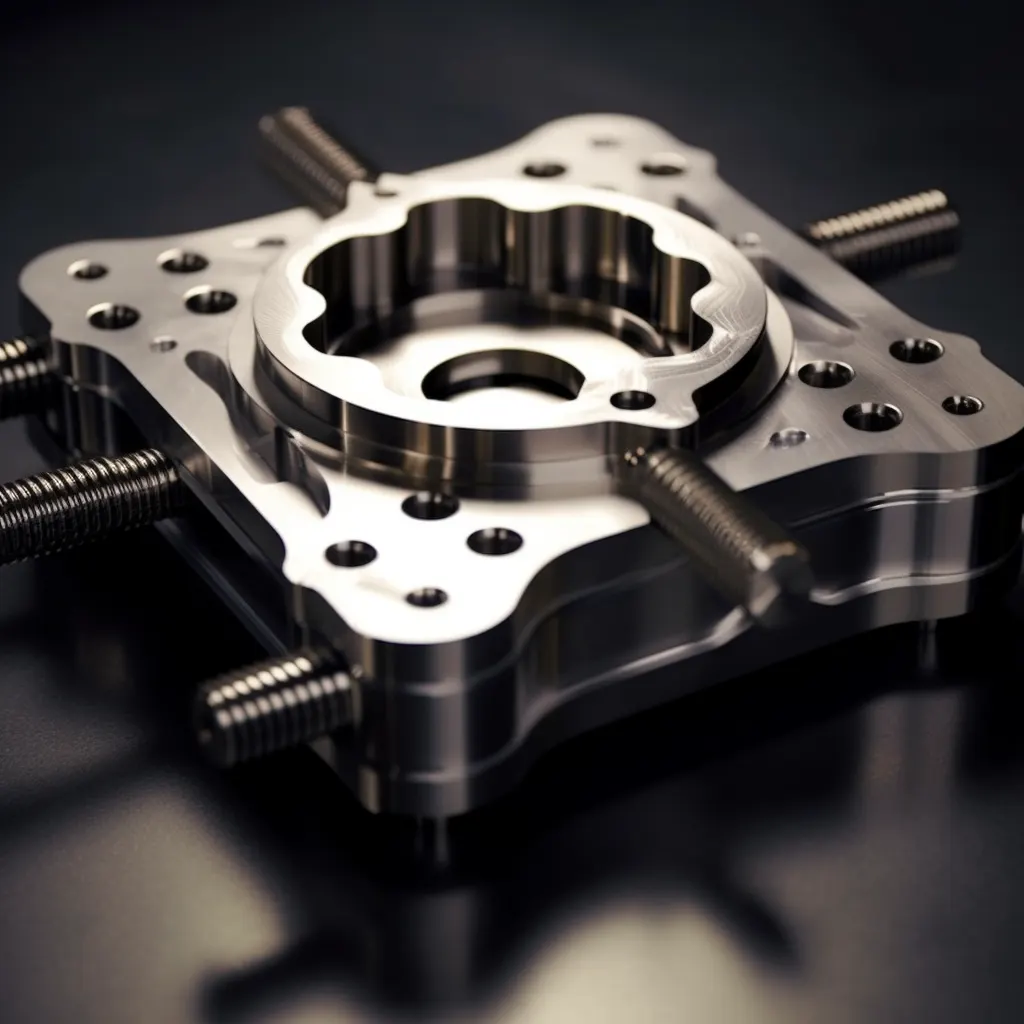

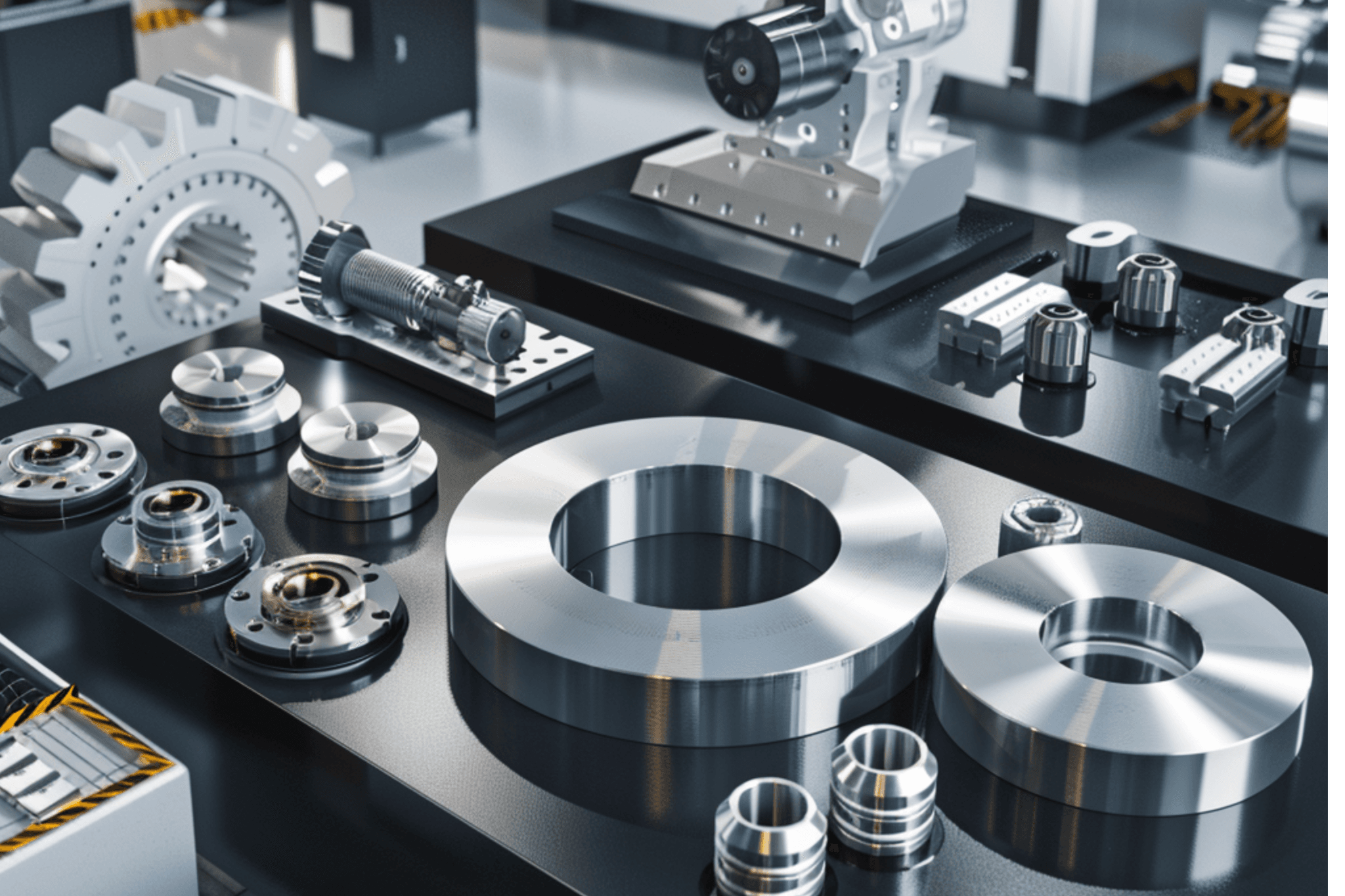

Our Diverse Range of CNC Turning Solutions

Our diverse CNC turning solutions offer precision machining for complex parts, tailored to meet the unique needs of various industries.

Conventional CNC Turning

Conventional CNC turning precisely shapes cylindrical parts, providing accurate and consistent results for various manufacturing needs.

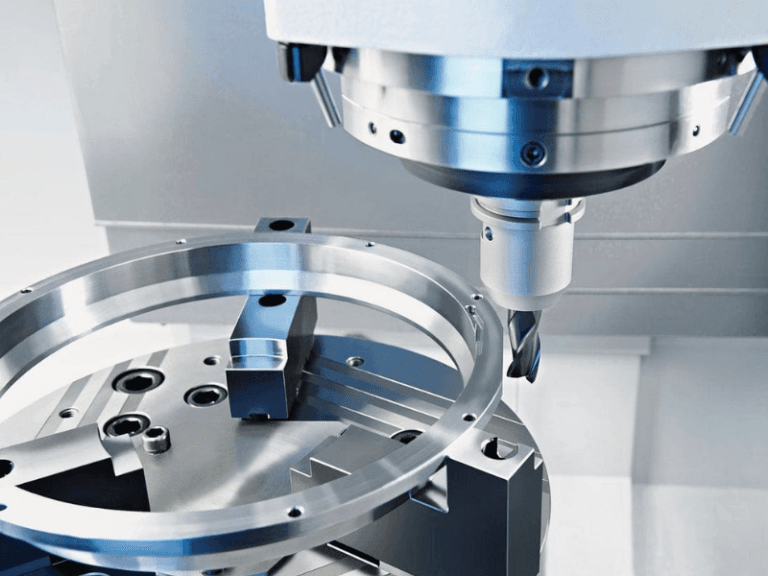

Multi- Axis CNC Turning

Multi-axis CNC turning offers increased precision and versatility, enabling the machining of complex and detailed parts.

Live Tooling CNC Turning

Live tooling in CNC turning allows for precise machining of complex parts, enhancing efficiency and versatility.

.png)

Hard Turning

Hard turning, also known as turning instead of grinding, is the final processing or finishing of martensitic structural steel with high hardness, high strength, and almost no plasticity after quenching.

Tight Tolerance

In CNC turning, tight tolerance ensures precise dimensions, critical for demanding applications, guaranteeing consistency and accuracy in manufactured parts.

Quick Lead Times

Benefiting from CNC turning, we promise quick lead times. Our efficient processes deliver precision parts promptly, meeting your tight deadlines reliably.

Fast Response Capabilities

Our quick response capabilities, integrated with CNC turning, guarantee timely delivery of precise components to fulfill your production requirements.

Innovative Problem Solving

In CNC turning, innovative problem-solving ensures efficient solutions for complex machining challenges, ensuring precision and optimal performance.

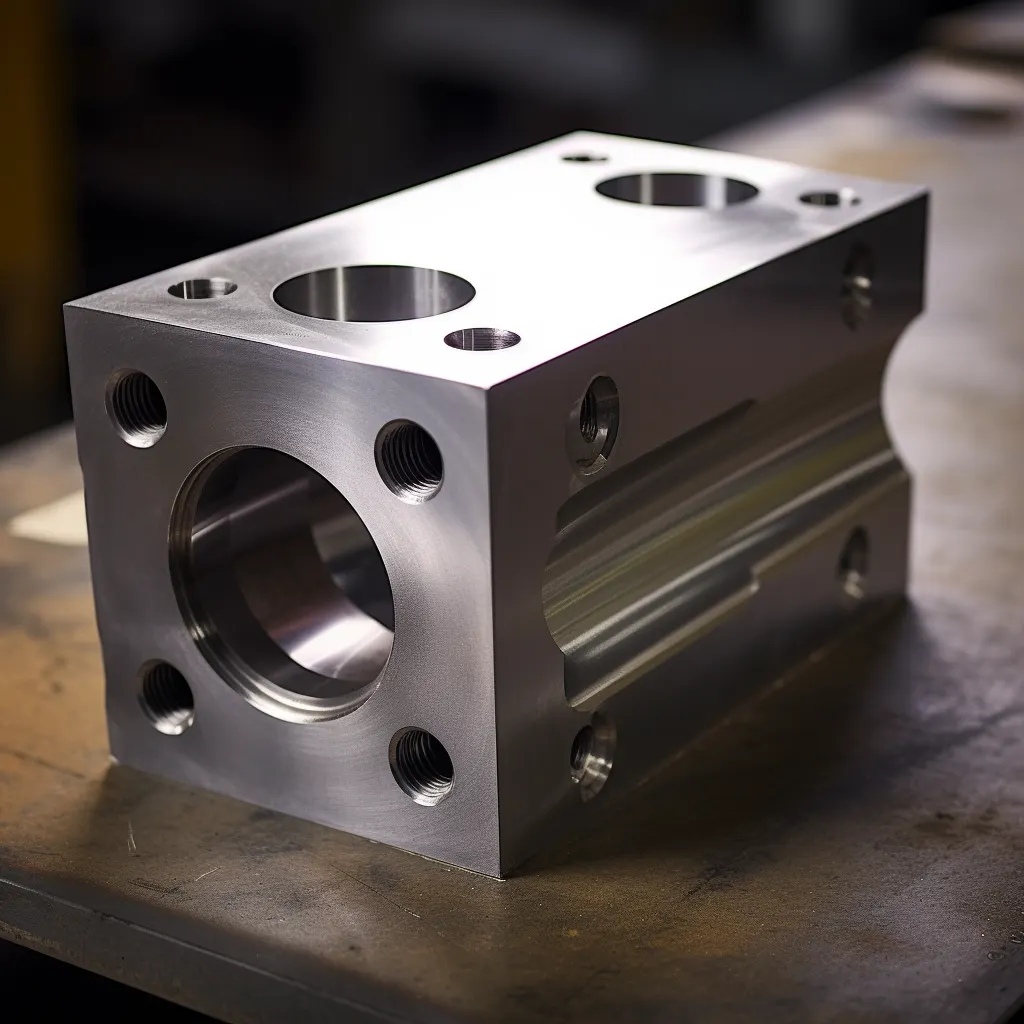

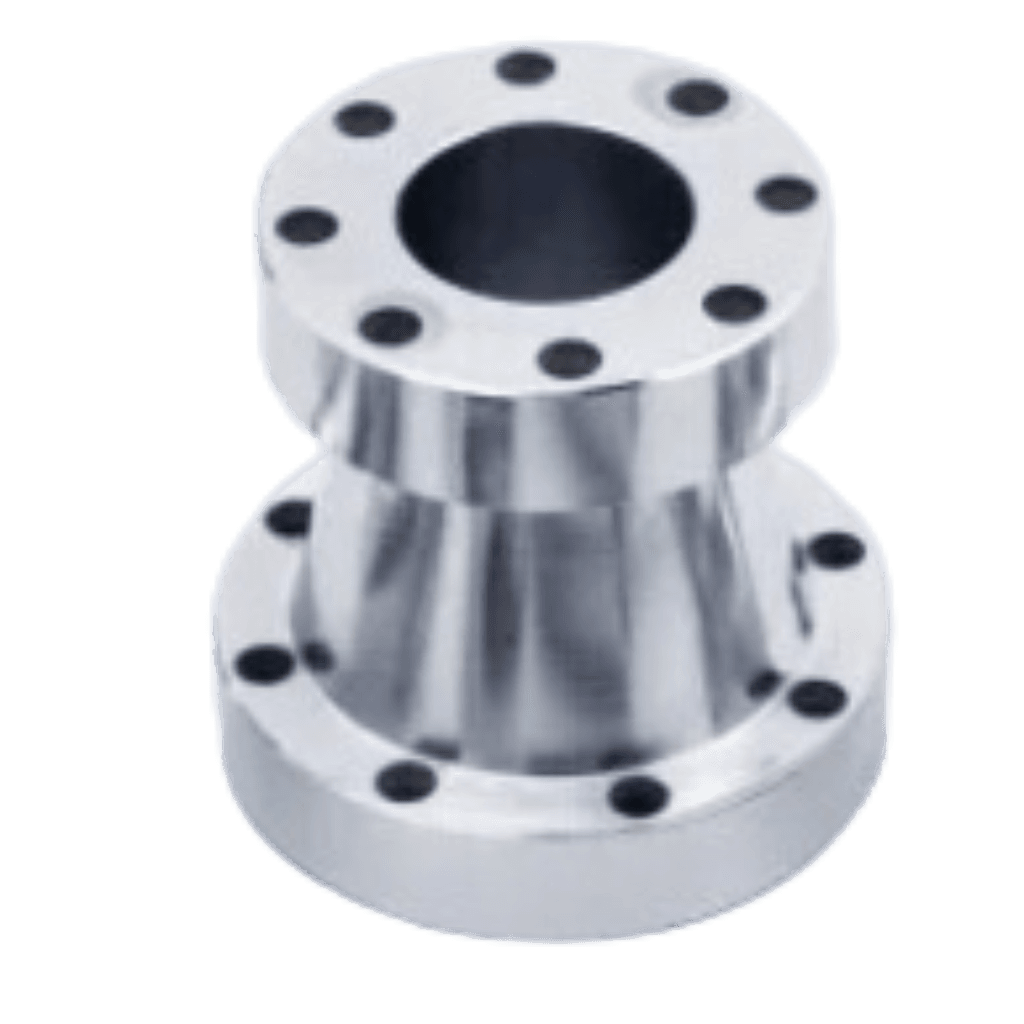

Gallery of CNC Machined Parts

Why Choose Us for CNC Turning Services

-1.png)

Precision & Accuracy

CNC turning ensures precision and quality in manufacturing, delivering accurate, high-quality parts with consistent tight tolerances for various applications.

).png)

Speed & Efficiency

CNC turning offers exceptional speed and efficiency, enabling rapid production of high-precision parts with consistent quality and minimal waste.

Versatility in Materials and Complexity

CNC turning offers versatility in materials and complexity, handling metals, plastics, and composites with precision. It excels in producing intricate designs and complex geometries, meeting diverse manufacturing needs.

Cost- Effectiveness for Low and High Volume

CNC turning offers cost-effectiveness for both low and high volume production. It ensures precision and efficiency, reducing material waste and labor costs.

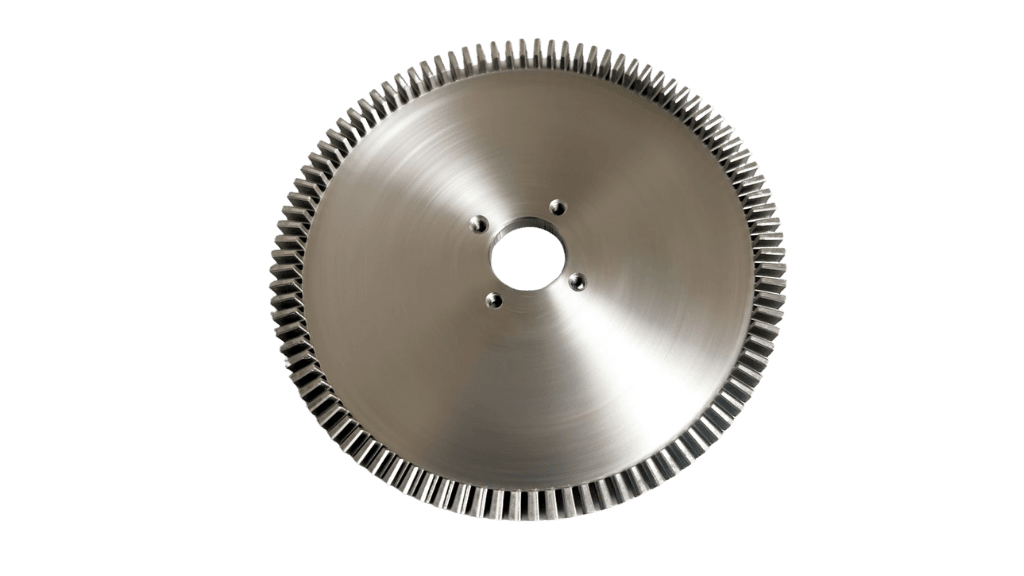

PART STUDY

High-Precision Stainless Steel Gear

Material: 1.4305 (SUS 303)

Surface Treatment: Passivation

Qty: 220 Pcs

Application: This product can be used in mechanical and automotive industries for making gears, shafts, and cutting tools due to its excellent machinability and corrosion resistance.

Explore CNC Turning Resources

CNC Turning

Home CNC Turning Services Our CNC turning service offers precise, efficient machining for various components. Using advanced equipment, we produce accurate parts tailored to your