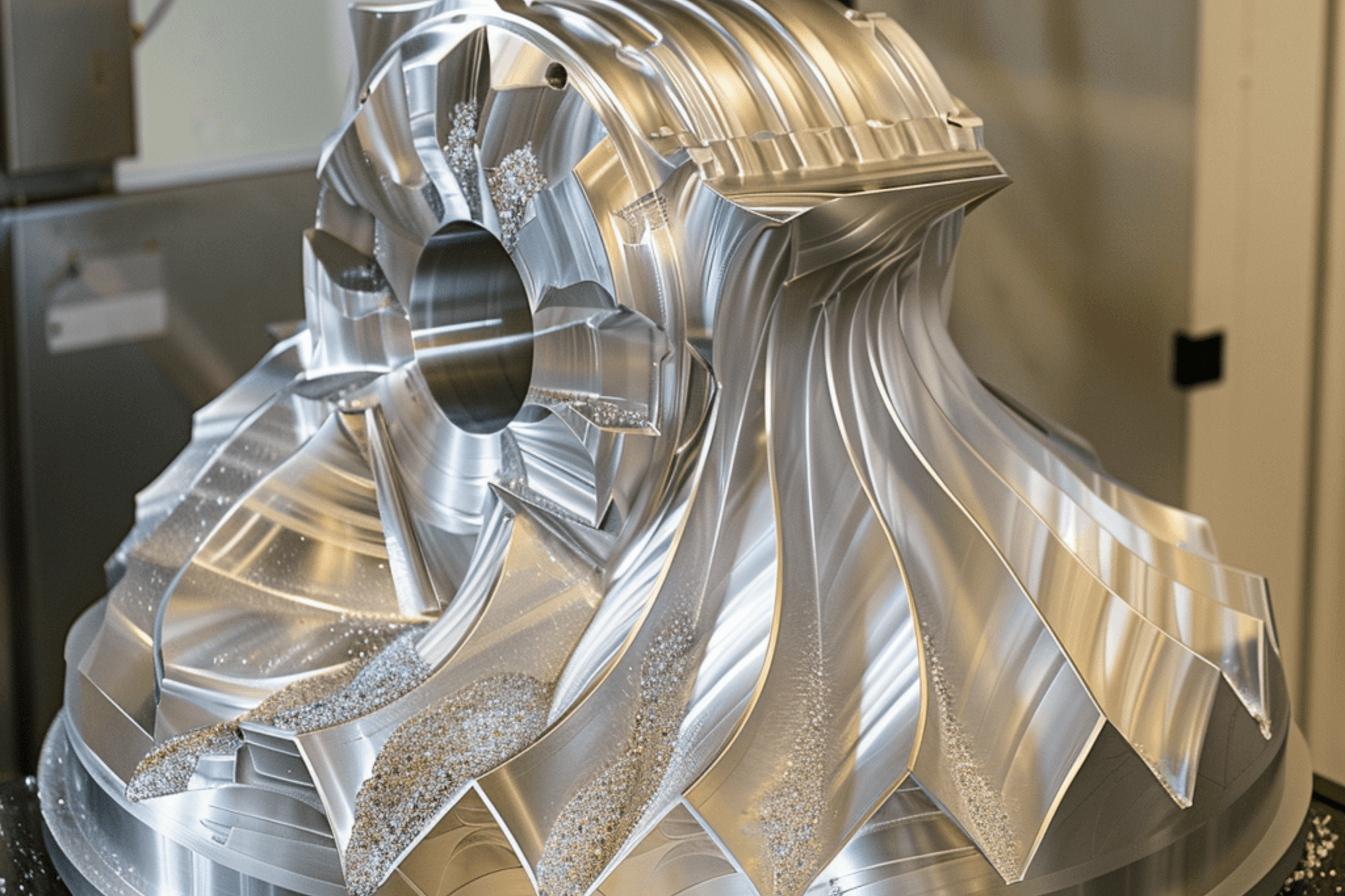

precision 5-Axis CNC Machining Service

Witcool’s 5-axis CNC machining produces complex, precise parts with tight tolerances, faster setup, and high accuracy—ideal for aerospace, automotive, and medical industries.

- Advanced Multi-Axis Machining

- Quick Production Turnaround

- Cost-Effective for High-Volume Production

- Experienced and Skilled Workforce

Trusted by

Professional Team

Our professional team delivers exceptional expertise and dedication to meet all your project needs.

One-Stop Service

One-stop service from prototyping to finishing, streamlining your sourcing process.

Top Quality

We provide high-quality 5-Axis Machining services with precision, durability, and exceptional craftsmanship.

Fast Delivery

Enjoy fast delivery with Witcool, ensuring your orders arrive quickly and efficiently every time.

Low Cost

We offer low-cost 5-Axis CNC machining services with guaranteed precision, quality, and reliable delivery.

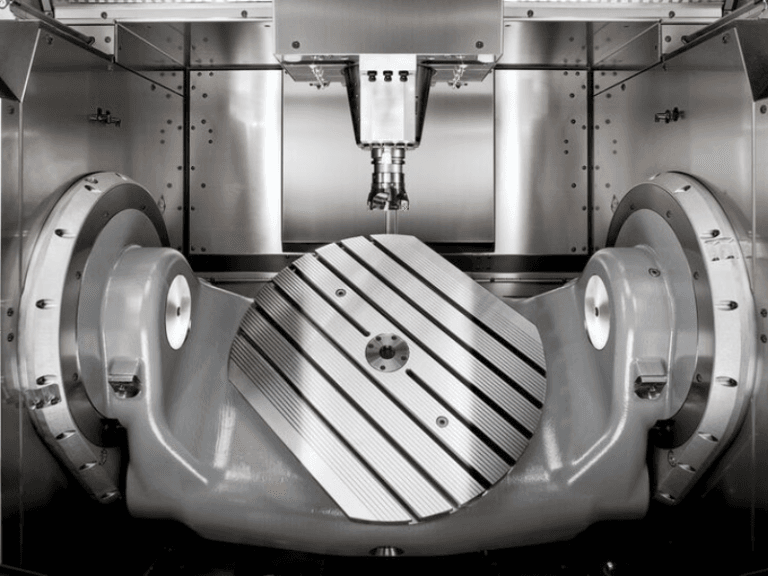

Introduction to 5-Axis Machining

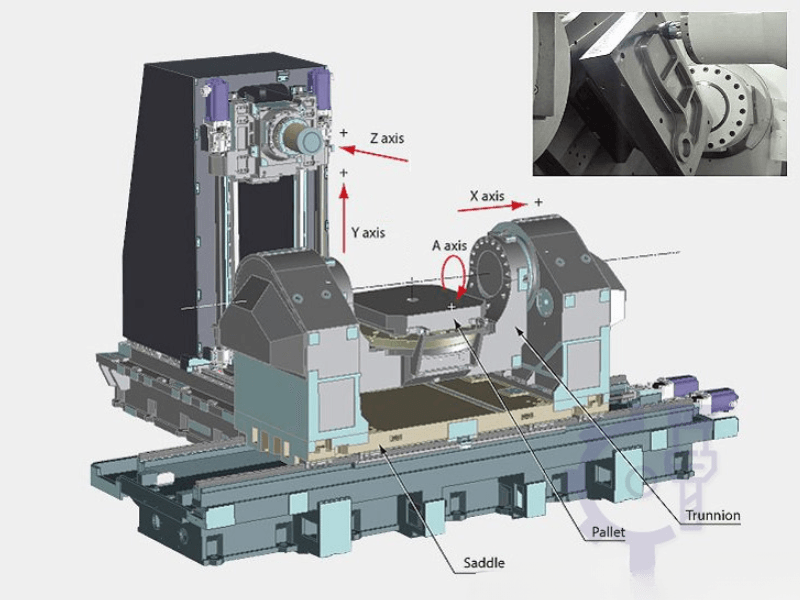

The height of precision engineering, 5-axis machining lets one create intricate shapes with until unheard-of accuracy. Our five-axis machines can move a cutting tool or part along five separate axes concurrently, unlike conventional three-axis machining, therefore facilitating the effective manufacture of complex components.

5-axis CNC machining is the technique whereby a piece of material is shaped by use of a cutting tool capable of five directions of motion. Approaching the workpiece from anywhere, the tool travels along the X, Y, and Z linear axes and spins on the A and B axes. Over three-axis machining, in which the tool travels just along the X, Y, and Z axes, this adaptability offers major benefits.

5-axis machining offers mostly enhanced accuracy, efficiency, and speed. It reduces machining time by allowing complicated cuts in one configuration, therefore removing the need for several setups. Higher quality components with closer tolerances and a smoother finish follow from this. 5-axis machines also fit sectors including aerospace, automotive, and medical devices as they can manage more complicated geometries and forms.

An adaptable technique that enhances the precision, efficiency, and speed of the produced product is 5-axis CNC machining It reduces machining time by allowing complicated cuts in one configuration, therefore removing the need for several setups. Parts requiring precise motions or where GD&T datums and features gain from minimum setups are best suited for 5-axis machines.

5-axis machining presents a better answer for clients trying to improve their production capacity. In the competitive manufacturing scene of today, its ability to create intricate components with great accuracy and low lead times is priceless.

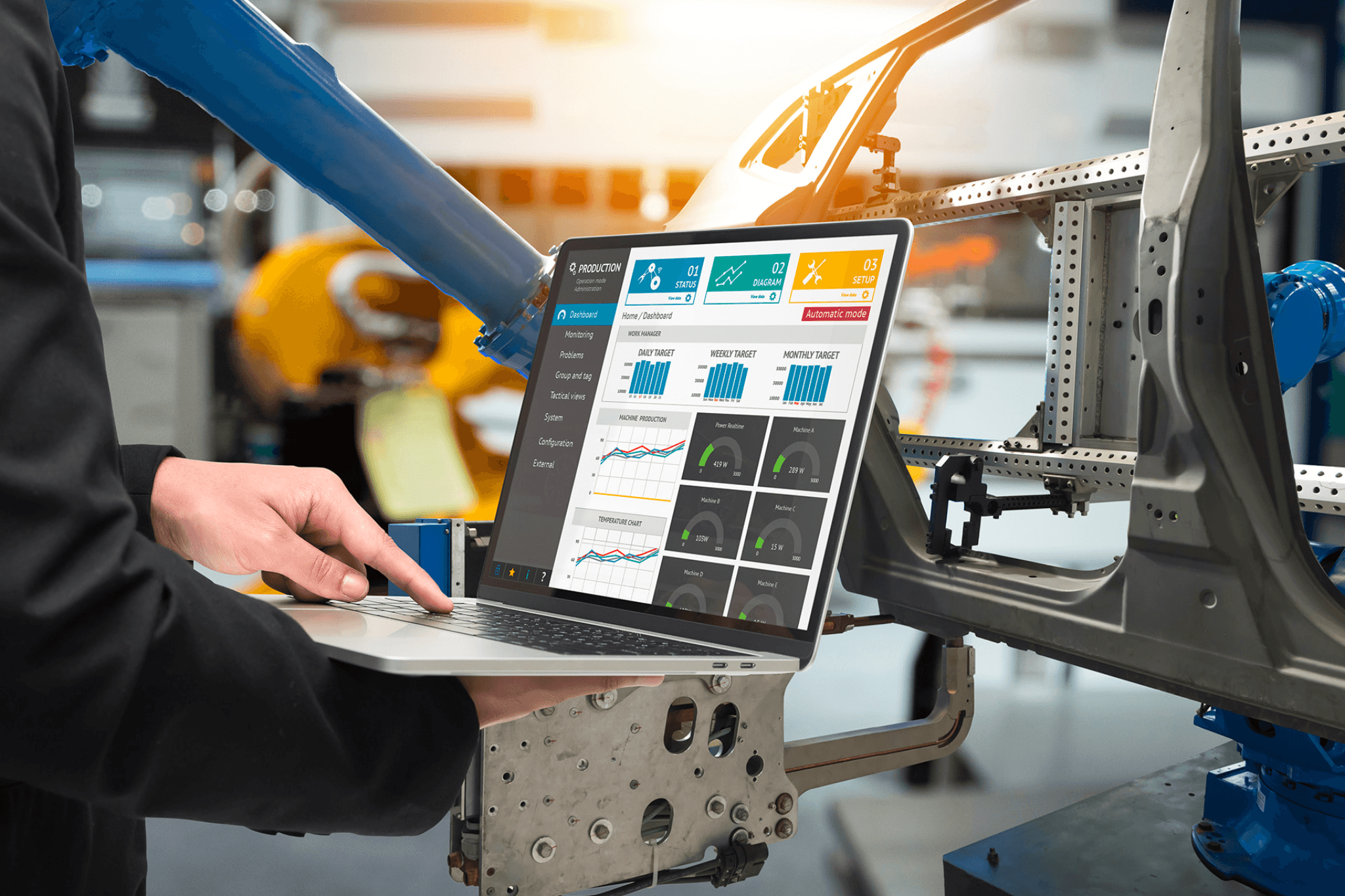

5-Axis CNC Machining Capabilities

Our 5-axis CNC machining delivers precise, complex components quickly and efficiently, meeting exacting industry standards.

Simultaneous 5 Axis CNC Machining

Experience simultaneous 5-axis CNC machining for unparalleled precision and efficiency, producing intricate parts with minimal setups and reduced lead times.

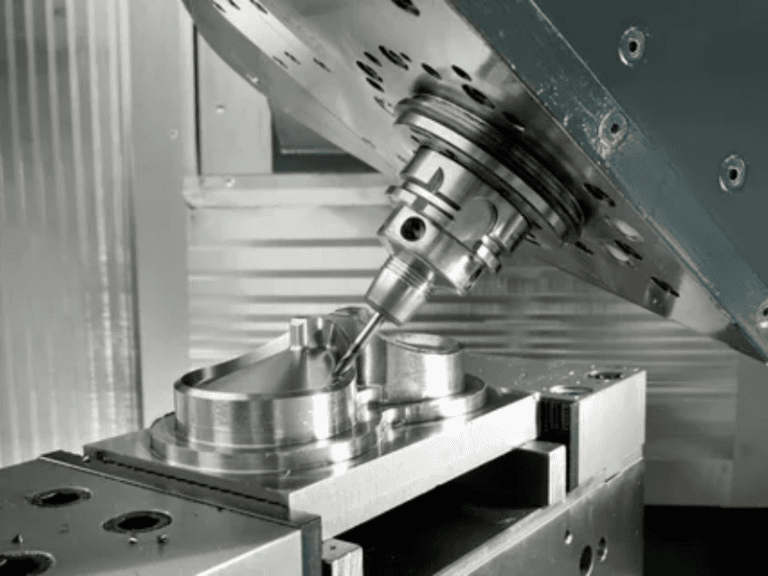

3+2 Axis CNC Machining

Our 3+2 axis CNC machining combines flexibility and precision, allowing for efficient production of complex parts with reduced setups.

Our Feauture in 5-Axis CNC Machining

Tight Tolerance

Our 5-axis CNC machining ensures tight tolerances, providing exceptional precision for complex parts, meeting stringent industry specifications and standards.

Quick Lead Times

Experience quick lead times with our advanced 5-axis CNC machining, ensuring rapid production of complex parts with exceptional precision and efficiency.

Fast Response Capabilities

Benefit from our rapid response capabilities in 5-axis CNC machining, ensuring quick turnaround and high-quality production for complex components.

Innovative Problem Solving

Utilizing 5-axis CNC machining for innovative problem solving results in precise, versatile solutions for complex engineering challenges with exceptional efficiency.

Why Choose 5-Axis CNC Machining

Achieve unmatched precision and efficiency with simultaneous multi-axis movement, enabling complex geometries, reduced setups, and superior quality for demanding industries like aerospace, automotive, and medical.

Precision & Quality

5-axis CNC machining ensures unparalleled precision and quality in manufacturing, delivering intricate, high-quality parts with consistent tight tolerances for various complex applications. This advanced technology allows for the creation of highly detailed and accurate components, minimizing errors and ensuring superior quality.

Complex Geometries & Flexibility

5-axis CNC machining enables the production of complex geometries and shapes that are difficult or impossible to achieve with traditional 3-axis machining. This flexibility allows for the efficient manufacturing of intricate designs, reducing the need for multiple setups and ensuring a higher degree of accuracy.

Efficiency & Reduced Lead Times

With 5-axis CNC machining, multiple faces of a part can be machined in a single setup, significantly reducing lead times and increasing production efficiency. This capability minimizes downtime between operations and enhances throughput, ensuring faster turnaround times for complex projects.

Cost-Effectiveness & Material Savings

By reducing the number of setups and operations required, 5-axis CNC machining can lower labor costs and material waste. This efficiency translates into cost savings for both low and high-volume production runs, making it a cost-effective solution for producing complex, high-precision parts.

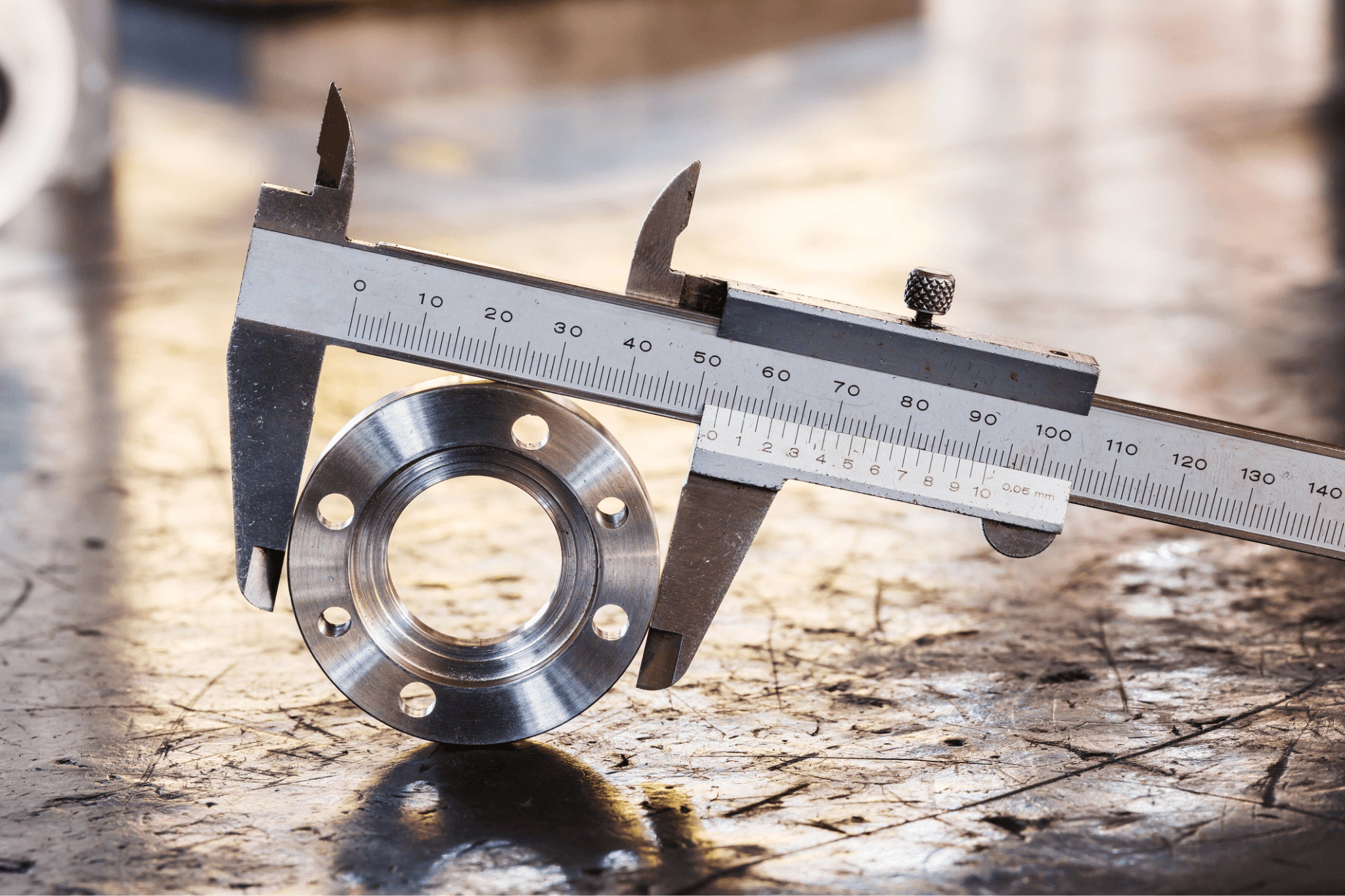

5-Axis CNC Machining Tolerances

Capable of achieving extremely tight tolerances, often within ±0.0004 mm, ensuring exceptional accuracy, consistency, and quality for complex parts across aerospace, medical, and high-precision industries.

Standards

Tolerance

Common Tolerance

0.0004” (±10μm / ±0.01mm)

Standard Tolerance

Metals: ISO2768-f Plastics: ISO 2768-m

Linear Dimension

Φ 0.5mm

Hole Dimension (notreamed)

±0.025mm

Shaft Diameters

±0.025mm

Edge Condition

Sharp corner will be removed in the form of a chamler or radius. The size of the chamler, or resulting radii, must be indicated on the drawing.

Threads and Tapped Holes

Diameter: Φ 5 mm or more Depth: 4-6×diameter

Text / Engraving Content

Sharp corner will be removed in the form of a chamler or radius. The size of the chamler, or resulting radii, must be indicated on the drawing.

Lead Time

10 business days <100 Pcs

PART STUDY

5 Axis Stator Back Cover For Drone Accessories

Material: Aluminum 6082 T

Surface Treatment: Bead Blasted+ Anodized Black

Qty: 10Pcs

Application: Used in the manufacturing of aviation and aerospace components, particularly for drone accessories, where high precision, durability, and lightweight properties are critical.

Questions & Answers

At Witcool, we maintain strict control over every stage of the 3D Printing process, ensuring high product quality and precision. We deliver reliable solutions by adhering to standards and implementing innovations to enhance every project.

How does 3D printing work?

The digital model is sliced into layers, and the printer deposits material sequentially—melting or curing—to build the object from the bottom up.

What are the most common types of 3D printing technologies?

Common processes include FDM (FFF), SLA, SLS, DLP, MJF, and DMLS/EBM, each suited for different materials and precision levels.

What materials can be used?

Printers commonly use PLA, ABS, PETG, TPU, Nylon, polycarbonate, resins, and even metals, ceramics, or bio-materials.

STL file format: what is it and why is it used?

The STL format, developed in 1987, encodes the object’s surface geometry using triangles and remains the most widely accepted format for slicing and printing.

What are the key advantages and disadvantages of 3D printing?

Advantages: custom geometries, reduced material waste, rapid prototyping, manufacturing flexibility.

Disadvantages: slower for large parts, size constraints, limited scalability, high cost for some processes.

Which industries use 3D printing the most?

It’s used in aerospace, automotive, medicine, education, architecture, consumer products, and defense, especially for prototyping and custom parts.